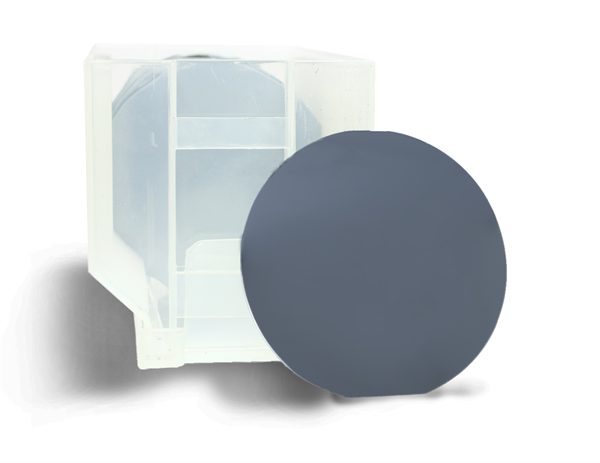

SiC substrate P-mofuta 4H/6H-P 3C-N 4inch e nang le botenya ba 350um Sehlopha sa Tlhahiso ea Dummy

4inch SiC substrate P-mofuta 4H/6H-P 3C-N parameter tafole

4 silika bophara ba lisenthimitharaKarolo e nyenyane ea Carbide (SiC). Tlhaloso

| Kereiti | Zero MPD Tlhahiso Kereiti (Z Kereiti) | Tlhahiso e Tloaelehileng Kereiti (P Kereiti) | Sehlopha sa Dummy (D Kereiti) | ||

| Diameter | 99.5 limilimithara ~ 100.0 limilimithara | ||||

| Botenya | 350 μm ± 25 μm | ||||

| Wafer Orientation | Ka thoko: 2.0°-4.0° ho leba [1120] ± 0.5° bakeng sa 4H/6H-P, On axis:〈111〉± 0.5° bakeng sa 3C-N | ||||

| Boima ba Micropipe | 0cm-2 | ||||

| Ho hanyetsa | mofuta oa 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-mofuta 3C-N | ≤0.8 mΩꞏcm | ≤1 m Ωꞏcm | |||

| Maemo a Motheo a Flat | 4H/6H-P | - {1010} ± 5.0° | |||

| 3C-N | - {110} ± 5.0° | ||||

| Bolelele ba Phatlalatso ba Pele | 32.5 limilimithara ± 2.0 limilimithara | ||||

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ± 2.0 limilimithara | ||||

| Boemo ba Bobeli ba Flat | Sefahleho sa silicon holimo: 90° CW. ho tloha ho Prime flat±5.0° | ||||

| Kenyelletso ea Edge | 3 limilimithara | 6 limilimithara | |||

| LTV/TTV/Bow /Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Boqhobane | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Leseli | Ha ho letho | Bolelele bo akaretsang ≤ 10 mm, bolelele bo le bong≤2 mm | |||

| Hex Plates By High Intensity Light | Kakaretso ≤0.05% | Kakaretso ≤0.1% | |||

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Ha ho letho | Kakaretso≤3% | |||

| Likakaretso tsa Carbon tse bonoang | Kakaretso ≤0.05% | Kakaretso ≤3% | |||

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Ha ho letho | Bolelele ba kakaretso≤1× bophara ba wafer | |||

| Edge Chips Phahameng ka ho Matla Leseli | Ha ho e lumelletsoeng ≥0.2mm bophara le botebo | 5 e lumelletsoe, ≤1 mm ka 'ngoe | |||

| Tšilafalo ea Sefahleho sa Silicon Ka Matla a Phahameng | Ha ho letho | ||||

| Sephutheloana | Multi-wafer Cassette kapa Single Wafer Container | ||||

Lintlha:

※ Meeli ea bofokoli e sebetsa sebakeng sohle sa wafer ntle le sebaka se ka thoko. # Mengoallo e lokela ho hlahlojoa ho Si face feela.

Mofuta oa P-mofuta oa 4H/6H-P 3C-N 4-inch SiC substrate e nang le botenya ba 350 μm e sebelisoa haholo tlhahisong e tsoetseng pele ea lisebelisoa tsa elektroniki le lisebelisoa tsa matla. Ka conductivity e ntle ea mocheso, matla a phahameng a ho senyeha, le khanyetso e matla ea tikoloho e feteletseng, substrate ena e loketse lisebelisoa tsa motlakase tse sebetsang hantle tse kang li-switches tse phahameng, li-inverters le lisebelisoa tsa RF. Li-substrates tsa boemo ba tlhahiso li sebelisoa tlhahisong e kholo, ho netefatsa ts'ebetso ea lisebelisoa tse tšepahalang, tse nepahetseng haholo, tse bohlokoa bakeng sa lisebelisoa tsa elektronike tsa matla le lisebelisoa tse phahameng tsa maqhubu. Ka lehlakoreng le leng, li-substrates tsa dummy-grade li sebelisoa haholo bakeng sa ho lekanya tšebetso, tlhahlobo ea lisebelisoa, le nts'etsopele ea prototype, ho thusa ho boloka taolo ea boleng le ts'ebetso e tsitsitseng tlhahisong ea semiconductor.

SpecificationMelemo ea N-mofuta oa SiC composite substrates e kenyeletsa

- High Thermal Conductivity: Ho senya mocheso o sebetsang hantle ho etsa hore substrate e be e loketseng bakeng sa lisebelisoa tse phahameng tsa mocheso le matla a phahameng.

- Motlakase o phahameng oa ho senya: E ts'ehetsa ts'ebetso ea matla a phahameng, ho netefatsa ho ts'epahala ho lisebelisoa tsa elektronike le lisebelisoa tsa RF.

- Ho Hanyetsa Litikoloho tse Hloahloa: E tšoarella maemong a feteletseng joalo ka mocheso o phahameng le tikoloho e senyang, e netefatsang ts'ebetso e tšoarellang nako e telele.

- Tlhahiso-Kereiti Precision: E netefatsa ts'ebetso ea boleng bo holimo le e tšepahalang tlhahisong e kholo, e loketseng matla a tsoetseng pele le lits'ebetso tsa RF.

- Dummy-Grade bakeng sa Tlhahlobo: E thusa ho lekanya ts'ebetso e nepahetseng, tlhahlobo ea lisebelisoa, le prototyping ntle le ho senya li-wafers tsa boemo ba tlhahiso.

Ka kakaretso, mofuta oa P-mofuta oa 4H/6H-P 3C-N 4-inch SiC substrate e nang le botenya ba 350 μm e fana ka melemo e mengata bakeng sa lisebelisoa tsa elektronike tse sebetsang hantle. Mocheso oa eona o phahameng oa mocheso le motlakase oa ho senya o etsa hore e be o loketseng bakeng sa libaka tse phahameng tsa matla le mocheso o phahameng, ha ho hanyetsa maemo a thata ho tiisa ho tšoarella le ho tšepahala. Substrate ea boemo ba tlhahiso e netefatsa ts'ebetso e nepahetseng le e tsitsitseng tlhahisong e kholo ea lisebelisoa tsa motlakase le lisebelisoa tsa RF. Ho sa le joalo, substrate ea boemo ba dummy e bohlokoa bakeng sa ho lekanya ts'ebetso, tlhahlobo ea lisebelisoa, le prototyping, e ts'ehetsang taolo ea boleng le botsitso tlhahisong ea semiconductor. Likarolo tsena li etsa hore li-substrates tsa SiC li fetohe haholo bakeng sa lits'ebetso tse tsoetseng pele.

Setšoantšo se qaqileng