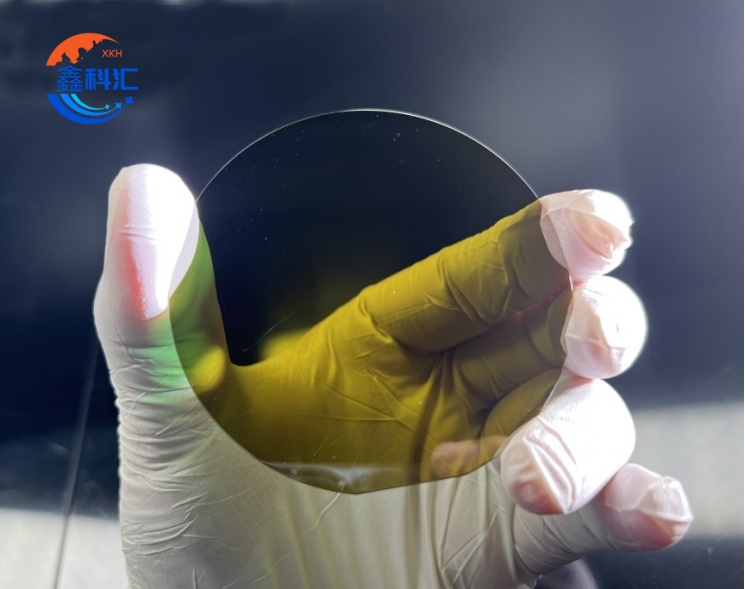

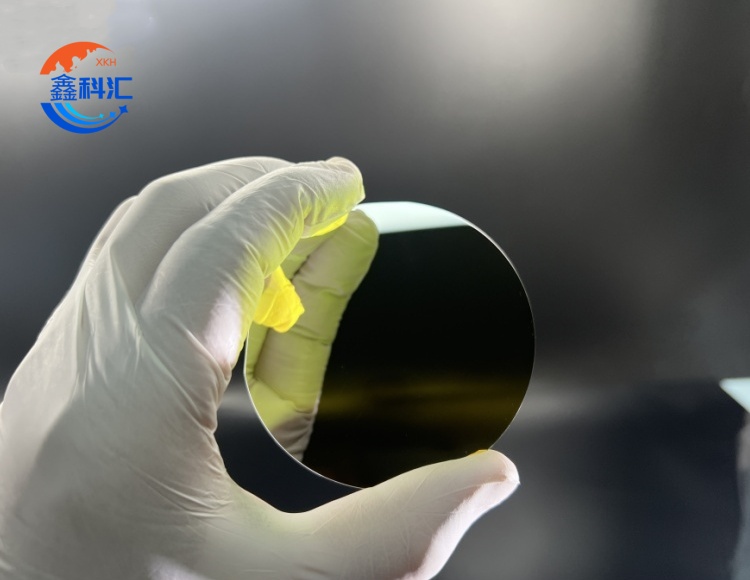

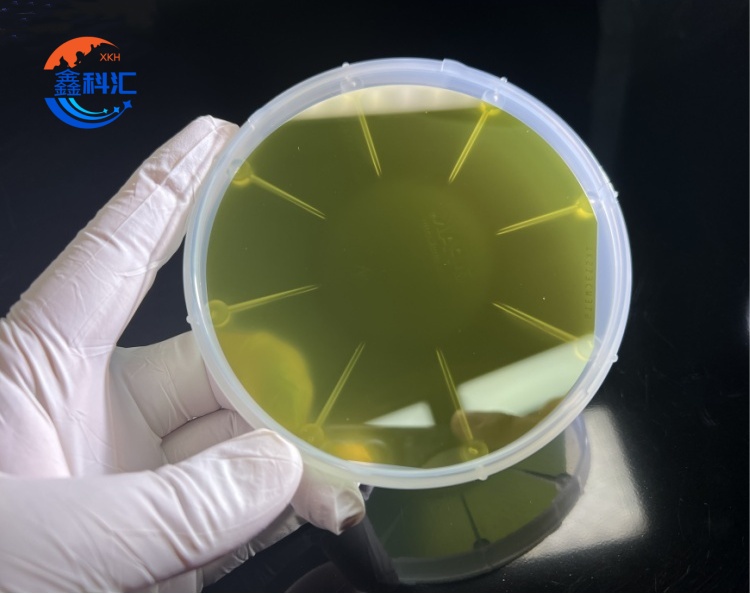

Sic Substrate Silicon Carbide Wafer 4H-N Type High Hardness Corrosion Resistance Prime Grade Polishing

Lintlha tse latelang ke litšobotsi tsa silicon carbide wafer

1. Mocheso o phahameng oa mocheso: Thermal conductivity ea SIC wafers e phahame haholo ho feta ea silicon, e bolelang hore li-wafers tsa SIC li ka senya mocheso ka katleho 'me li loketse ho sebetsa libakeng tse phahameng tsa mocheso.

2. Ho tsamaea ha elektronike e phahameng: Li-wafers tsa SIC li na le ho tsamaea ha elektronike ho feta silicon, ho lumella lisebelisoa tsa SIC hore li sebetse ka lebelo le phahameng.

3. Matla a phahameng a ho senya: lisebelisoa tsa SIC tsa wafer li na le matla a phahameng a ho senya, a etsang hore e be a loketseng ho etsa lisebelisoa tse phahameng tsa semiconductor.

4. Botsitso bo phahameng ba lik'hemik'hale: Li-wafers tsa SIC li na le khanyetso e matla ea lik'hemik'hale, e thusang ho ntlafatsa ho tšepahala le ho tšoarella ha sesebelisoa.

5. Lekhalo le pharaletseng la lihlopha: Li-wafers tsa SIC li na le lekhalo le pharaletseng la lihlopha ho feta silicon, li etsa hore lisebelisoa tsa SIC li be betere le tse tsitsitseng haholoanyane mochesong o phahameng.

Silicon carbide wafer e na le lisebelisoa tse 'maloa

1.Mechanical tšimo: lisebelisoa tsa ho itšeha le lisebelisoa tsa ho sila; Likarolo tse manganga le lihlahla; Li-valve tsa indasteri le litiiso; Li-bearings le libolo

2.Lebala la matla a elektronike: lisebelisoa tsa semiconductor tsa matla; High frequency microwave element; matla a phahameng a motlakase le mocheso o phahameng oa motlakase oa motlakase; Thepa ea tsamaiso ea mocheso

3.Indasteri ea lik'hemik'hale: mochine oa lik'hemik'hale le lisebelisoa; Liphaephe tse sa jeng le litanka tsa polokelo; Tšehetso ea lik'hemik'hale tsa lik'hemik'hale

4.Lefapha la Matla: turbine ea khase le likarolo tsa turbocharger; Likarolo tsa mantlha tsa matla a nyutlelie le likarolo tsa sebopeho sa mocheso o phahameng oa mocheso oa mafura

5.Aerospace: mekhoa ea ho sireletsa mocheso bakeng sa limisaele le likoloi tsa sebaka; Li-blades tsa turbine ea jet; Motsoako o tsoetseng pele

6.Libaka tse ling: Li-sensor tse phahameng tsa mocheso le li-thermopiles; Dies le lisebelisoa bakeng sa sintering tshebetso; Ho sila le ho bentša le ho seha masimo

ZMKJ e ka fana ka sephaphatha sa kristale se le seng sa boleng bo holimo ( Silicon Carbide ) indastering ea elektroniki le ea optoelectronic. SiC wafer ke thepa ea semiconductor ea moloko o latelang, e nang le thepa e ikhethang ea motlakase le thepa e ntle ea mocheso, ha e bapisoa le sephaephe sa silicon le sephaephe sa GaAs, sephaphatha sa SiC se loketse haholoanyane mocheso o phahameng le sesebelisoa sa matla a phahameng. SiC wafer e ka fanoa ka bophara ba 2-6 inch, ka bobeli 4H le 6H SiC, mofuta oa N, Nitrogen doped, le mofuta oa semi-insulating o fumanehang. Ka kopo ikopanye le rona bakeng sa lintlha tse ling mabapi le sehlahisoa.

Feme ea rona e na le lisebelisoa tse tsoetseng pele tsa tlhahiso le sehlopha sa botekgeniki, se ka khonang ho etsa litlhaloso tse fapaneng, botenya le libopeho tsa sephaphatha sa SiC ho latela litlhoko tse khethehileng tsa bareki.

Setšoantšo se qaqileng