SICOI (Silicon Carbide ka Insulator) Liphaephe tsa SiC Film KA Silicon

Setšoantšo se qaqileng

Kenyelletso ea li-wafers tsa Silicon Carbide ho Insulator (SICOI).

Li-wafers tsa Silicon Carbide on Insulator (SICOI) ke li-semiconductor substrates tsa moloko o latelang tse kopanyang thepa e phahameng ea 'mele le ea elektroniki ea silicon carbide (SiC) le litšobotsi tse ikhethang tsa motlakase tsa lera le sireletsang, joalo ka silicon dioxide (SiO₂) kapa silicon nitride (Si₃N₄). Sephaphatha se tloaelehileng sa SICOI se na le lesela le tšesaane la SiC ea epitaxial, filimi e kenang lipakeng, le substrate e tšehetsang, e ka bang silicon kapa SiC.

Sebopeho sena sa lebasetere se entsoe ho fihlela litlhoko tse thata tsa lisebelisoa tsa elektronike tse matla, tse phahameng, le tse nang le mocheso o phahameng. Ka ho kenyelletsa lera le sireletsang, li-wafers tsa SICOI li fokotsa matla a parasitic le ho hatella maqhubu a lutlang, ka hona li netefatsa maqhubu a phahameng a ts'ebetso, ts'ebetso e ntle le taolo e ntlafalitsoeng ea mocheso. Melemo ena e ba etsa ba bohlokoa haholo makaleng a kang likoloi tsa motlakase, lisebelisoa tsa mehala ea puisano ea 5G, litsamaiso tsa sefofane, lisebelisoa tsa elektroniki tsa RF tse tsoetseng pele, le theknoloji ea sensor ea MEMS.

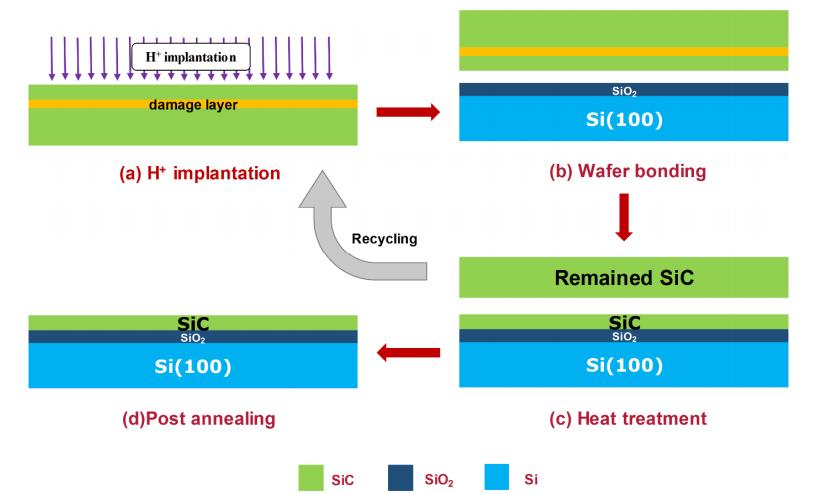

Molao-motheo oa Tlhahiso ea SICOI Wafers

Li-wafers tsa SICOI (Silicon Carbide on Insulator) li etsoa ka mokhoa o tsoetseng pelesephaphatha bonding le thinning tshebetso:

-

Khōlo ea SiC Substrate- Sephaphatha sa boleng bo phahameng ba kristale ea SiC (4H / 6H) se lokiselitsoe e le thepa ea bafani.

-

Insulating Layer Deposition- Filimi e sireletsang (SiO₂ kapa Si₃N₄) e thehoa holim'a sejana sa thepa (Si kapa SiC).

-

Wafer Bonding- Sephaphatha sa SiC le sephaphatha se tsamaisang li hokahantsoe hammoho tlas'a mocheso o phahameng kapa thuso ea plasma.

-

Ho tšesaane le ho benya- The SiC donor wafer e tšesaane ho isa ho li-micrometer tse 'maloa' me e bentšitsoe ho fihlela sebaka se boreleli sa athomo.

-

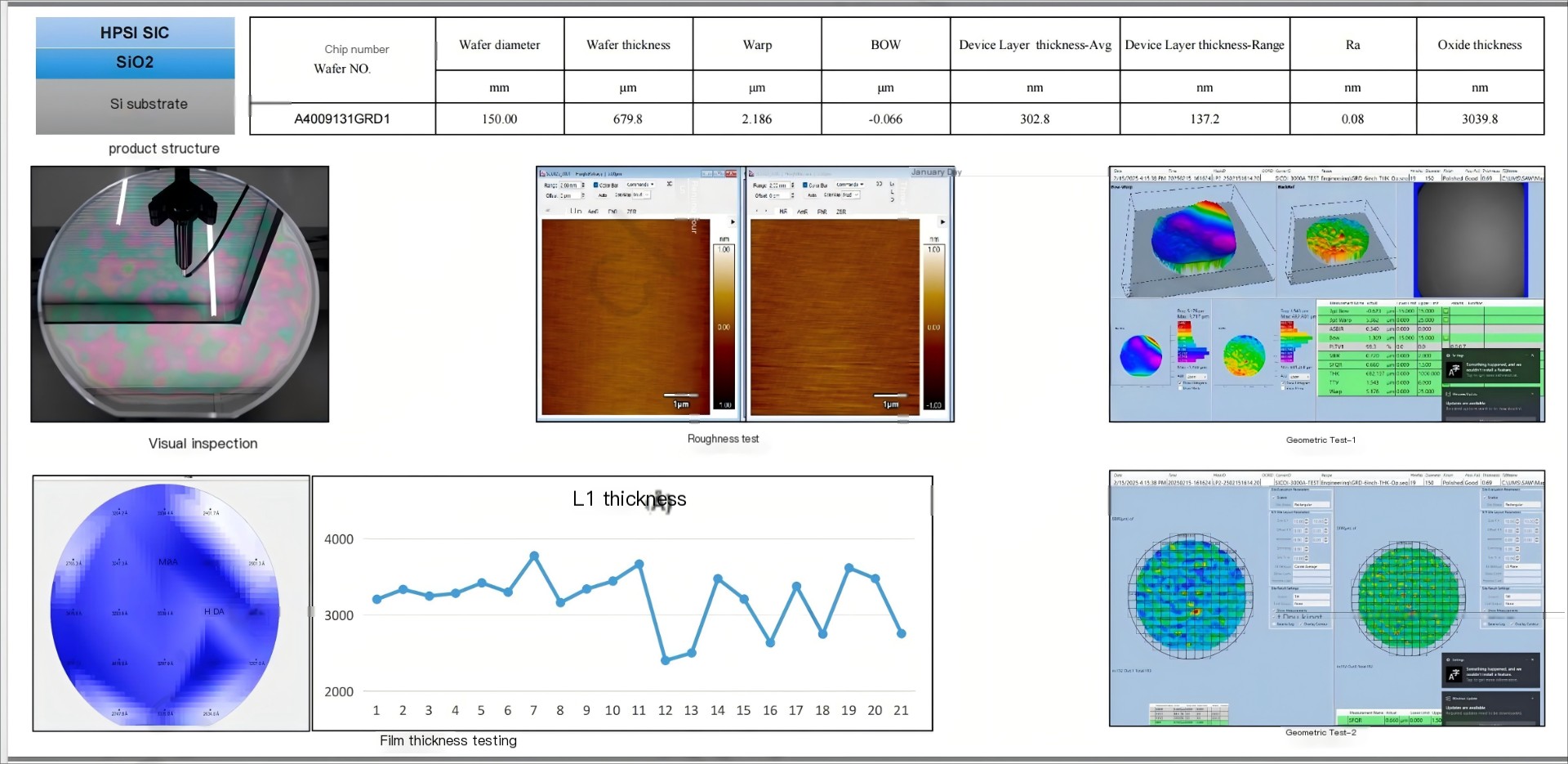

Tlhahlobo ea ho Qetela- Sephaphatha sa SICOI se phethiloeng se lekoa bakeng sa ho lekana ha botenya, ho ba mahoashe holimo, le ts'ebetso ea ho pata.

Ka mokhoa ona, alera le tšesaane le sebetsang la SiCe nang le thepa e babatsehang ea motlakase le ea mocheso e kopantsoe le filimi e sireletsang le substrate ea tšehetso, ho theha sethala se phahameng sa ts'ebetso ea matla a moloko o latelang le lisebelisoa tsa RF.

Melemo ea Bohlokoa ea SICOI Wafers

| Sehlopha sa Feature | Litšobotsi tsa Theknoloji | Melemo ea Konokono |

|---|---|---|

| Sebopeho sa Lintho | 4H/6H-SiC e sebetsang lera + filimi e sireletsang (SiO₂/Si₃N₄) + Si kapa SiC carrier | E fihlella karohano e matla ea motlakase, e fokotsa tšitiso ea likokoana-hloko |

| Thepa ea Motlakase | Matla a matla a ho senya (> 3 MV / cm), tahlehelo e tlaase ea dielectric | E etselitsoe ts'ebetso ea maqhubu a phahameng le maqhubu a phahameng |

| Thermal Properties | Thermal conductivity ho fihla ho 4.9 W/cm·K, e tsitsitseng ka holimo ho 500°C | Ho senya mocheso ka katleho, ts'ebetso e babatsehang tlas'a meroalo e matla ea mocheso |

| Thepa ea Mechini | Boima bo feteletseng (Mohs 9.5), coefficient e tlase ea katoloso ea mocheso | E matla khahlanong le khatello ea maikutlo, e ntlafatsa bophelo bo bolelele ba sesebelisoa |

| Boleng ba Sefahleho | Bokaholimo bo boreleli (Ra <0.2 nm) | E khothaletsa epitaxy e se nang sekoli le ho etsa lisebelisoa tse tšepahalang |

| Insulation | Ho hanyetsa >10¹⁴ Ω·cm, ho dutla ho tlase hona jwale | Ts'ebetso e tšepahalang ho RF le lits'ebetso tsa ho itšehla thajana tse phahameng haholo |

| Size & Customization | E fumaneha ka mefuta ea 4, 6, le 8-inch; Botenya ba SiC 1-100 μm; insulation 0.1-10 μm | Moralo o feto-fetohang bakeng sa litlhoko tse fapaneng tsa kopo |

Libaka tsa Kopo tsa Konokono

| Lekala la Kopo | Maemo a Tloaelehileng a Tšebeliso | Melemo ea Ts'ebetso |

|---|---|---|

| Matla a Elektronike | Li-inverters tsa EV, liteishene tsa ho tjhaja, lisebelisoa tsa motlakase tsa indasteri | Matla a phahameng a ho senya, ho fokotsa tahlehelo ea ho fetola |

| RF & 5G | Li-amplifiers tsa setsi sa motheo, likarolo tsa millimeter-wave | Li-parasitics tse tlase, li tšehetsa ts'ebetso ea GHz-range |

| Li-Sensors tsa MEMS | Li-sensor tsa khatello ea tikoloho e thata, MEMS ea boemo ba ho tsamaea | Botsitso bo phahameng ba mocheso, bo hanyetsanang le mahlaseli |

| Sefofane le Tšireletso | Lipuisano tsa satellite, li-module tsa matla a avionics | Ho tšepahala mochesong o feteletseng le ho pepesehela mahlaseli |

| Smart Grid | Li-converter tsa HVDC, li-circuit breakers tse tiileng | Insulation e phahameng e fokotsa tahlehelo ea matla |

| Optoelectronics | Li-LED tsa UV, li-laser substrates | Boleng bo phahameng ba kristale bo tšehetsa tlhahiso e sebetsang ea khanya |

Ho etsoa ha 4H-SiCOI

Tlhahiso ea li-wafers tsa 4H-SiCOI e finyelloa ka howafer bonding le thinning process, e nolofalletsang li-interfaces tsa boleng bo holimo le likarolo tse sebetsang tsa SiC tse se nang sekoli.

-

a: Schematic ea 4H-SiCOI e entsoeng ka sethaleng sa lisebelisoa.

-

b: Setšoantšo sa 4-inch 4H-SiCOI sephaphatha se sebelisa ho kopanya le ho fokotsa; libaka tse nang le bokooa tse tšoailoeng.

-

c: Botenya bo ts'oanang ba sebopeho sa substrate ea 4H-SiCOI.

-

d: Setšoantšo sa Optical sa 4H-SiCOI die.

-

e: Phallo ea ts'ebetso ea ho etsa resonator ea SiC microdisk.

-

f: SEM ea resonator e phethiloeng ea microdisk.

-

g: SEM e atolositsoeng e bonts'ang lebota la resonator; AFM e bonts'a boreleli ba nanoscale.

-

h: SEM e nang le likarolo tse fapaneng e bonts'ang bokaholimo ba sebopeho sa parabolic.

FAQ ka SICOI Wafers

Q1: Ke melemo efe eo li-wafer tsa SICOI li nang le tsona ho feta li-wafers tsa setso tsa SiC?

A1: Ho fapana le li-substrates tse tloaelehileng tsa SiC, li-wafers tsa SICOI li kenyelletsa lera le sireletsang le fokotsang matla a likokoana-hloko le maqhubu a lutlang, e leng se lebisang katlehong e phahameng, karabelo e ntle ea maqhubu, le ts'ebetso e phahameng ea mocheso.

Q2: Ke mefuta efe ea li-wafer e fumanehang hangata?

A2: Li-wafers tsa SICOI hangata li hlahisoa ka liforomo tsa 4-inch, 6-inch, le 8-inch, tse nang le SiC e ikhethileng le botenya ba lera la insulating le fumanehang ho latela litlhoko tsa sesebelisoa.

Q3: Ke liindasteri life tse ruang molemo haholo ho li-wafers tsa SICOI?

A3: Liindasteri tsa bohlokoa li kenyelletsa matla a motlakase bakeng sa likoloi tsa motlakase, lisebelisoa tsa elektronike tsa RF bakeng sa marang-rang a 5G, MEMS bakeng sa li-sensor tsa aerospace, le optoelectronics tse kang UV LEDs.

Q4: Lera la insulating le ntlafatsa ts'ebetso ea sesebelisoa joang?

A4: Filimi e sireletsang (SiO₂ kapa Si₃N₄) e thibela ho lutla ha hona joale le ho fokotsa puisano ea motlakase, e leng se nolofalletsang ho mamella motlakase o phahameng, ho fetoha ka mokhoa o sebetsang haholoanyane, le ho fokotsa tahlehelo ea mocheso.

Q5: Na li-wafers tsa SICOI li loketse lits'ebetso tsa mocheso o phahameng?

A5: E, ka conductivity e phahameng ea mocheso le ho hanyetsa ho feta 500 ° C, li-wafers tsa SICOI li etselitsoe ho sebetsa ka botšepehi tlas'a mocheso o feteletseng le libakeng tse thata.

Q6: Na li-wafers tsa SICOI li ka etsoa ka mokhoa o ikhethileng?

A6: Ho joalo. Baetsi ba fana ka meralo e hlophisitsoeng bakeng sa botenya bo itseng, maemo a doping, le motsoako oa substrate ho fihlela litlhoko tse fapaneng tsa lipatlisiso le indasteri.