SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si subatrate sebopeho

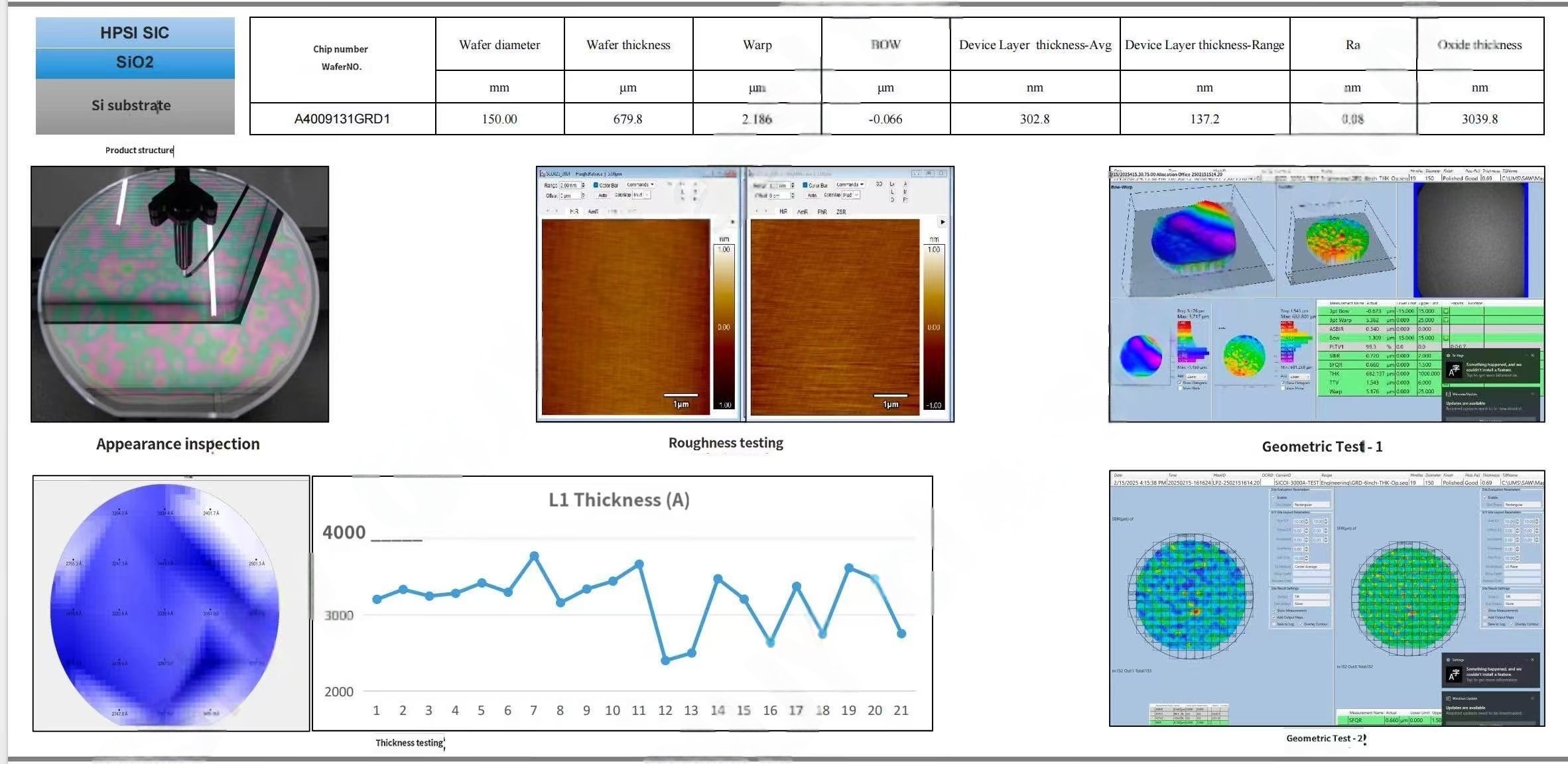

Sebopeho sa sephaphatha sa SiCOI

HPB (High-Performance Bonding) BIC (Bonded Integrated Circuit) le SOD (Silicon-on-Diamond kapa theknoloji e kang Silicon-on-Insulator-like). E kenyelletsa:

Melemo ea Ts'ebetso:

E thathamisa liparamente tse kang ho nepahala, mefuta ea liphoso (mohlala, "Ha ho phoso," "Bohole ba boleng"), le litekanyo tsa botenya (mohlala, "Direct-Layer thickness/kg").

Tafole e nang le litekanyetso tsa linomoro (mohlomong tsa liteko kapa tsa ts'ebetso) tlasa lihlooho tse kang "ADDR/SYGBDT," "10/0," joalo-joalo.

Lintlha tsa Botenya ba Lera:

Maikutlo a mangata a pheta-phetoang a ngotsoeng "L1 Thickness (A)" ho "L270 Thickness (A)" (mohlomong ho Ångströms, 1 Å = 0.1 nm).

E fana ka tlhahiso ea sebopeho se nang le lilae tse ngata se nang le taolo e nepahetseng ea botenya bakeng sa lera ka leng, le tloaelehileng ho li-wafers tse tsoetseng pele tsa semiconductor.

Sebopeho sa SiCOI Wafer

SiCOI (Silicon Carbide on Insulator) ke mohaho o khethehileng oa sephaphatha o kopanyang silicon carbide (SiC) e nang le lesela le sireletsang, le ts'oanang le SOI (Silicon-on-Insulator) empa e ntlafalitsoe bakeng sa lisebelisoa tse phahameng tsa matla / mocheso o phahameng. Lintlha tsa bohlokoa:

Sebopeho sa Lera:

Lera le ka Holimo: Silicon Carbide e le 'ngoe ea kristale (SiC) bakeng sa motsamao o phahameng oa elektronike le botsitso ba mocheso.

Insulator e patiloeng: Ka tloaelo SiO₂ (oxide) kapa daemane (ka SOD) ho fokotsa capacitance ea parasitic le ho ntlafatsa ho itšehla thajana.

Base Substrate: Silicon kapa polycrystalline SiC bakeng sa tšehetso ea mochini

Lisebelisoa tsa SiCOI

Thepa ea Motlakase Wide Bandgap (3.2 eV bakeng sa 4H-SiC): E nolofalletsa matla a phahameng a ho senya (> 10 × ho feta silicon) .E fokotsa maqhubu a ho lutla, ho ntlafatsa bokhoni ba lisebelisoa tsa matla.

High Electron Mobility:~900 cm²/V·s (4H-SiC) khahlano le ~1,400 cm²/V·s (Si), empa tšebetso e ntlafetseng ea sebaka se phahameng.

Boikutlo bo fokolang:Li-transistors tse thehiloeng ho SiCOI (mohlala, li-MOSFET) li bonts'a tahlehelo e tlase ea ho tsamaisa.

Insulation e ntle haholo:oxide e patiloeng (SiO₂) kapa lera la daemane le fokotsa matla a parasitic le crosstalk.

- Thermal PropertiesHigh Thermal Conductivity:SiC (~490 W/m·K for 4H-SiC) vs. Si (~150 W/m·K) .Taemane (haeba e sebelisoa e le insulator) e ka feta 2,000 W/m·K, e matlafatsa ho qhala ha mocheso.

Thermal Stability:E sebetsa ka botshepehi ho >300°C (vs. ~ 150°C bakeng sa silicon) .E fokotsa ditlhoko tsa ho phodisa mahlaleng a motlakase.

3. Mechanical & Chemical PropertiesBothata bo Feteletseng (~ 9.5 Mohs): E hana ho apara, e etsa hore SiCOI e tšoarelle nako e telele bakeng sa tikoloho e thata.

Inertness ea lik'hemik'hale:E hanana le oxidation le corrosion, leha e le maemong a acidic/alkaline.

Katoloso e Tlase ea Thermal:E lumellana hantle le lisebelisoa tse ling tsa mocheso o phahameng (mohlala, GaN).

4. Melemo ea Sebopeho (ha e bapisoa le Bulk SiC kapa SOI)

Litahlehelo tsa Substrate tse Fokotseng:Insulating layer e thibela ho lutla ha hona joale ho substrate.

Ts'ebetso e ntlafetseng ea RF:Theko e tlase ea parasitic capacitance e nolofalletsa ho fetoha ka potlako (e molemo bakeng sa lisebelisoa tsa 5G/mmWave).

Moralo o Fetohang:Thin SiC top layer e lumella lisebelisoa tse ntlafalitsoeng (mohlala, likanale tse tšesaane haholo ho li-transistors).

Papiso le SOI & Bulk SiC

| Thepa | SiCOI | SOI (Si/SiO₂/Si) | Bulk SiC |

| Lekhalo | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Thermal Conductivity | Holimo (SiC + taemane) | Tlase (SiO₂ e fokotsa ho phalla ha mocheso) | Holimo (SiC feela) |

| Ho senyeha ha Voltage | Holimo Haholo | E itekanetseng | Holimo Haholo |

| Litšenyehelo | E phahameng | Tlase | Phahameng ka ho Fetisisa (Pure SiC) |

Lisebelisoa tsa SiCOI

Matla a Elektronike

Li-wafers tsa SiCOI li sebelisoa haholo lisebelisoa tsa semiconductor tse matla a phahameng le a phahameng joalo ka li-MOSFET, Schottky diode le li-switches tsa motlakase. Lekhalo le pharalletseng le li-voltage tse phahameng tsa SiC li thusa ho fetolela matla hantle ka tahlehelo e fokotsehileng le ts'ebetso e ntlafalitsoeng ea mocheso.

Lisebelisoa tsa Radio Frequency (RF).

Sekoaelo sa li-wafers tsa SiCOI se fokotsa bokhoni ba likokoana-hloko, se etsa hore se tšoanelehe bakeng sa li-transistors tse phahameng le li-amplifiers tse sebelisoang mehala ea puisano, radar le theknoloji ea 5G.

Lisebelisoa tsa Microelectromechanical (MEMS)

Li-wafers tsa SiCOI li fana ka sethala se matla sa ho etsa li-sensor tsa MEMS le li-activator tse sebetsang ka ts'epo maemong a thata ka lebaka la ho se sebetse ha lik'hemik'hale tsa SiC le matla a mochini.

Lisebelisoa tsa Elektronike tsa Mocheso o Phahameng

SiCOI e thusa lisebelisoa tsa elektronike tse bolokang ts'ebetso le ho tšepahala ha mocheso o phahameng, ho ruisa likoloi, lifofane le lisebelisoa tsa indasteri moo lisebelisoa tse tloaelehileng tsa silicon li hlōlehang.

Lisebelisoa tsa Photonic le Optoelectronic

Motsoako oa thepa ea optical ea SiC le lera la insulating li thusa ho kopanngoa ha lipotoloho tsa photonic le tsamaiso e ntlafetseng ea mocheso.

Mahlaseli a Elektronike a Hardened

Ka lebaka la mamello ea tlhaho ea mahlaseli a SiC, li-wafers tsa SiCOI li loketse sebaka le lisebelisoa tsa nyutlelie tse hlokang lisebelisoa tse mamellang tikoloho ea mahlaseli a phahameng.

Lipotso le Likarabo tsa SiCOI oafer

Q1: Sephaphatha sa SiCOI ke eng?

A: SiCOI e emetse Silicon Carbide-on-Insulator. Ke sebopeho sa semiconductor wafer moo lesela le tšesaane la silicon carbide (SiC) le hokeloang holim'a lera le sireletsang (hangata silicon dioxide, SiO₂), e tšehetsoeng ke silicon substrate. Sebopeho sena se kopanya thepa e babatsehang ea SiC le ho itšehla thajana ha motlakase ho tloha ho insulator.

Q2: Melemo ea mantlha ea li-wafers tsa SiCOI ke life?

A: Melemo e ka sehloohong e kenyelletsa matla a ho senyeha ha motlakase, li-bandgap tse pharaletseng, conductivity e ntle ea mocheso, boima bo phahameng ba mochine, le ho fokotsa matla a parasitic ka lebaka la lera la insulating. Sena se lebisa ts'ebetsong e ntlafetseng ea lisebelisoa, ts'ebetso, le ho tšepahala.

Q3: Ke lisebelisoa life tse tloaelehileng tsa li-wafers tsa SiCOI?

A: Li sebelisoa ho lisebelisoa tsa motlakase tsa motlakase, lisebelisoa tsa RF tsa maqhubu a phahameng, li-sensor tsa MEMS, lisebelisoa tsa elektronike tse nang le mocheso o phahameng, lisebelisoa tsa photonic, le lisebelisoa tsa motlakase tse thatafalitsoeng ke mahlaseli.

Setšoantšo se qaqileng