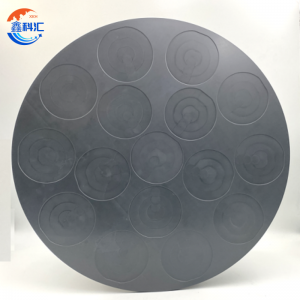

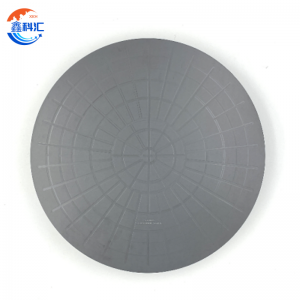

Silicon Carbide Ceramic Tray - Literei tse tšoarellang, tse sebetsang hantle haholo bakeng sa lits'ebetso tse futhumatsang le tsa lik'hemik'hale.

Setšoantšo se qaqileng

Kenyelletso ea Sehlahisoa

Silicon carbide (SiC) literei tsa ceramic ke likarolo tse sebetsang hantle tse sebelisoang haholo tikolohong ea liindasteri tse nang le mocheso o phahameng, mojaro o moholo le o thata oa lik'hemik'hale. E entsoe ka lisebelisoa tse tsoetseng pele tsa silicon carbide ceramic, literei tsena li etselitsoe ho fana ka matla a ikhethang a mochini, ho tsamaisa mocheso o phahameng, le ho hanyetsa ka mokhoa o tsotehang ho ts'oenyeha ha mocheso, oxidation le corrosion. Sebopeho sa bona se matla se etsa hore li tšoanelehe haholo bakeng sa lits'ebetso tse fapaneng tsa indasteri ho kenyelletsa tlhahiso ea semiconductor, photovoltaic process, sintering of powder metallurgy parts, le tse ling.

Li-trays tsa silicon carbide li sebetsa e le lijari tsa bohlokoa kapa litšehetso nakong ea ts'ebetso ea kalafo ea mocheso moo ho nepahala ha boholo, bots'epehi ba sebopeho, le ho hanyetsa lik'hemik'hale ho bohlokoa. Ha ho bapisoa le lisebelisoa tsa khale tsa ceramic tse kang alumina kapa mullite, literei tsa SiC li fana ka ts'ebetso e phahameng haholo, haholo-holo maemong a kenyelletsang ho palama baesekele e futhumetseng khafetsa le maemo a leholimo a mabifi.

Mokhoa oa Tlhahiso le Sebopeho sa Lintho

Tlhahiso ea li-tray tsa SiC ceramic e kenyelletsa boenjiniere bo nepahetseng le mahlale a tsoetseng pele a sintering ho netefatsa hore ho na le sekhahla se phahameng, sebopeho sa microstructure se ts'oanang, le ts'ebetso e tsitsitseng. Mehato e akaretsang e kenyelletsa:

-

Khetho ea Lintho tse tala

Ho khethiloe phofo e phahameng ea silicon carbide (≥99%), hangata e nang le taolo e khethehileng ea boholo ba likaroloana le litšila tse fokolang ho tiisa thepa e phahameng ea mechine le ea mocheso. -

Mekhoa ea ho Etsa

Ho ipapisitse le lintlha tsa tray, mekhoa e fapaneng ea ho etsa e sebelisoa:-

Cold Isostatic Pressing (CIP) bakeng sa li-compact tse ngata tse phahameng, tse tšoanang

-

Extrusion kapa slip casting bakeng sa dibopeho tse rarahaneng

-

Ho etsa ente bakeng sa lijeometri tse nepahetseng, tse qaqileng

-

-

Sintering Techniques

'Mele o motala o tšeloa ka mocheso o phahameng haholo, hangata o le ka har'a 2000 ° C, tlas'a moea o sa tsitsang kapa oa vacuum. Mekhoa e tloaelehileng ea sintering e kenyelletsa:-

Reaction Bonded SiC (RB-SiC)

-

Pressureless Sintered SiC (SSiC)

-

Recrystallized SiC (RBSiC)

Mokhoa o mong le o mong o fella ka thepa e fapaneng hanyane, joalo ka porosity, matla le conductivity ea mocheso.

-

-

Precision Machining

Kamora ho chesoa, literei li entsoe ka mochini ho fihlela mamello e tiileng, pheletso e boreleli le ho bata. Liphekolo tsa holim'a metsi tse kang ho phunya, ho sila le ho bentša li ka sebelisoa ho latela litlhoko tsa bareki.

Lisebelisoa tse Tloaelehileng

Li-tray tsa ceramic tsa silicon carbide li sebelisoa liindastering tse fapaneng ka lebaka la ho feto-fetoha ha tsona le ho tiea ha tsona. Lisebelisoa tse tloaelehileng li kenyelletsa:

-

Indasteri ea Semiconductor

Li-trays tsa SiC li sebelisoa e le lijari nakong ea li-wafer annealing, diffusion, oxidation, epitaxy, le mekhoa ea ho kenngoa. Ho tsitsa ha bona ho tiisa kabo e tšoanang ea mocheso le tšilafalo e fokolang. -

Indasteri ea Photovoltaic (PV).

Tlhahisong ea lisele tsa letsatsi, li-trays tsa SiC li tšehetsa li-ingots kapa li-wafers tsa silicon nakong ea mocheso o phahameng oa mocheso le mehato ea sintering. -

Metallurgy ea phofo le Ceramics

E sebelisoa bakeng sa likarolo tse tšehetsang nakong ea ho chesoa ha phofo ea tšepe, lirafshoa le lisebelisoa tse kopaneng. -

Liphanele tsa Khalase le Pontšo

E sebelisoa e le li-trays kapa sethala sa ho etsa likhalase tse khethehileng, li-substrates tsa LCD, kapa lisebelisoa tse ling tsa optical. -

Tšebetso ea Lik'hemik'hale le Libeiso tsa Thermal

Sebetsa joalo ka lijari tse sa jeng ka har'a li-reactor tsa lik'hemik'hale kapa joalo ka literei tse tšehetsang mocheso ka har'a libopi tse se nang moea le tse laoloang tsa sepakapaka.

Lintlha tsa Ts'ebetso ea Bohlokoa

-

✅Thermal Stability e ikhethang

E mamella ts'ebeliso e tsoelang pele mochesong o fihlang ho 1600-2000 ° C ntle le ho kheloha kapa ho senyeha. -

✅Matla a Phahameng a Mechini

E fana ka matla a phahameng a ho feto-fetoha (hangata> 350 MPa), ho netefatsa hore nako e telele e tšoarella esita le tlas'a maemo a phahameng a boima. -

✅Thermal Shock Resistance

Ts'ebetso e babatsehang libakeng tse nang le ho fetoha ha mocheso ka potlako, ho fokotsa kotsi ea ho senya. -

✅Corrosion le Oxidation Resistance

E tsitsitse ka lik'hemik'hale ho li-acids tse ngata, li-alkalis, le likhase tse oxidizing / tse fokotsang, tse loketseng lits'ebetso tse matla tsa lik'hemik'hale. -

✅Ho Nepaha ha Dimensional le Flatness

E entsoe ka nepo e phahameng, e netefatsa ts'ebetso e ts'oanang le e tsamaellanang le litsamaiso tse ikemetseng. -

✅Nako e Telele ea Bophelo & Tšebeliso ea Litšenyehelo

Litefiso tse tlase tsa ho nchafatsa le ho fokotsa litšenyehelo tsa tlhokomelo li etsa hore e be tharollo e sa jeng chelete e ngata ha nako e ntse e ea.

Litlhaloso tsa Tekheniki

| Paramethara | Boleng bo Tlwaelehileng |

|---|---|

| Lintho tse bonahalang | Reaction Bonded SiC / Sintered SiC |

| Max. Mocheso oa ho sebetsa | 1600–2000°C |

| Flexural Matla | ≥350 MPa |

| Botenya | ≥3.0 g/cm³ |

| Thermal Conductivity | ~120–180 W/m·K |

| Bophahamo bo Sephara | ≤ 0.1 limilimithara |

| Botenya | 5–20 limilimithara (ka tloaelo) |

| Litekanyo | Standard: 200×200 limilimithara, 300×300 limilimithara, joalo-joalo. |

| Surface Finish | E entsoe ka mochini, e bentšitsoe (ka kopo) |

Lipotso tse atisang ho botsoa (FAQ)

Q1: Na li-trays tsa silicon carbide li ka sebelisoa liboping tsa vacuum?

A:Ee, literei tsa SiC li loketse tikoloho ea li-vacuum ka lebaka la ho tsoa ha tsona ho tlase, botsitso ba lik'hemik'hale, le ho hanyetsa mocheso o phahameng.

Q2: Na libopeho tsa tloaelo kapa li-slots li teng?

A:Ruri. Re fana ka lits'ebeletso tse ikhethileng ho kenyelletsa boholo ba terei, sebopeho, likarolo tsa bokaholimo (mohlala, li-grooves, masoba), le ho bentša bokaholimo ho fihlela litlhoko tse ikhethang tsa bareki.

Q3: SiC e bapisoa joang le literei tsa alumina kapa tsa quartz?

A:SiC e na le matla a phahameng, conductivity e betere ea mocheso, le ho hanyetsa ho hoholo ha mocheso oa mocheso le ho bola ha lik'hemik'hale. Le ha alumina e na le litšenyehelo tse ngata, SiC e sebetsa betere maemong a boima.

Q4: Na ho na le botenya bo tloaelehileng bakeng sa literei tsee?

A:Botenya hangata bo maemong a 5-20 mm, empa re ka bo fetola ho latela kopo ea hau le litlhoko tsa ho jara mojaro.

Q5: Ke nako efe e tloaelehileng ea ho etella pele bakeng sa literei tsa SiC tse ikhethileng?

A:Linako tsa ho etella pele li fapana ho latela ho rarahana le bongata empa hangata li tloha libeke tse 2 ho isa ho tse 4 bakeng sa liodara tse ikhethileng.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.