Silicon carbide ceramic tray sucker Silicon carbide ceramic tube e fana ka mocheso o phahameng oa sintering custom process

Lintlha tse ka sehloohong:

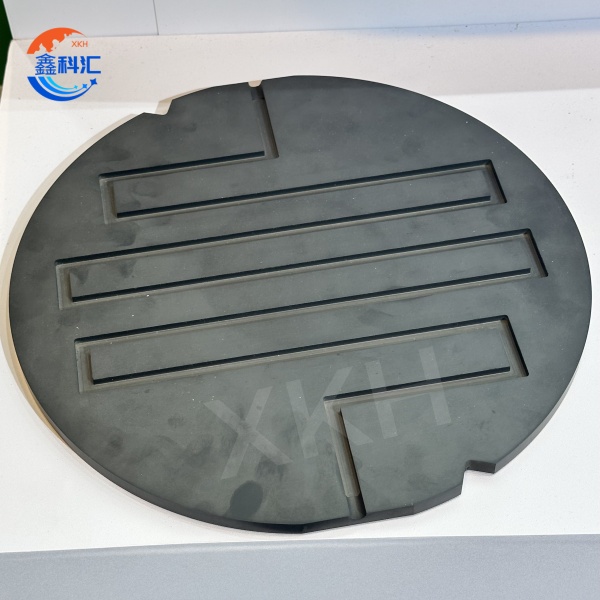

1. Silicon carbide ceramic tray

- Boima bo phahameng le ho hanyetsa ho roala: boima bo haufi le daemane, 'me bo ka mamella ho roala ha mochini ha ho etsoa li-wafer nako e telele.

- Ts'ebetso e phahameng ea mocheso le coefficient e tlase ea ho atolosa mocheso: ho senya mocheso ka potlako le botsitso ba dimensional, ho qoba deformation e bakoang ke khatello ea mocheso.

- Bophahamo bo phahameng le pheletso ea bokaholimo: Bophahamo ba bokaholimo bo fihla boemong ba micron, ho netefatsa hore ho kopana ka botlalo lipakeng tsa sephaphatha le disk, ho fokotsa tšilafalo le tšenyo.

Ho tsitsa ha lik'hemik'hale: Ho hanyetsa kutu ho matla, ho loketse bakeng sa ho hloekisa metsi le mekhoa ea etching tlhahisong ea semiconductor.

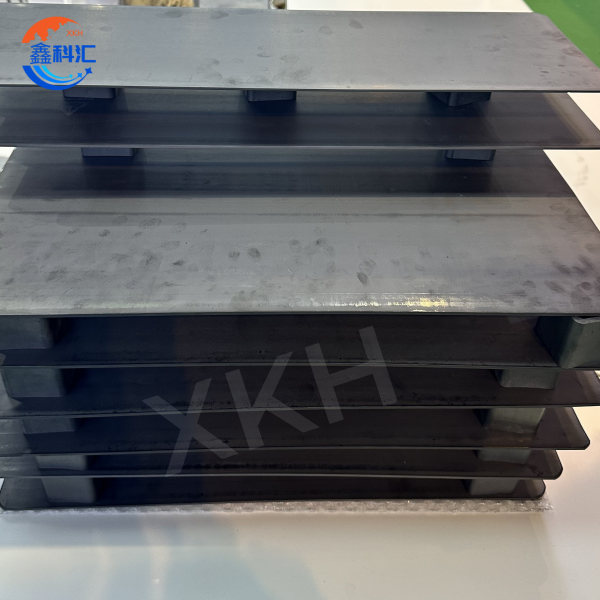

2. Silicon carbide ceramic tube

- Ho hanyetsa mocheso o phahameng: E ka sebetsa sebakeng sa mocheso o phahameng ka holimo ho 1600 ° C ka nako e telele, e loketseng mokhoa oa mocheso o phahameng oa semiconductor.

Ho hanyetsa kutu e ntle haholo: e hanyetsanang le li-acids, alkalis le mefuta e fapaneng ea metsoako ea lik'hemik'hale, e loketseng maemo a thata a ts'ebetso.

- Ho thatafala ho hoholo le ho hanyetsa ho roala: hanela khoholeho ea likaroloana le ho roala ha mochini, ho lelefatsa bophelo ba ts'ebeletso.

- Ts'ebetso e phahameng ea mocheso le coefficient e tlase ea ho atolosoa ha mocheso: ho tsamaisa ka potlako mocheso le botsitso ba dimensional, ho fokotsa deformation kapa ho phunyeha ho bakoang ke khatello ea mocheso.

Parameter ea sehlahisoa:

Silicon carbide ceramic tray parameter:

| (Thepa) | (Yuniti) | (sic) | |

| (Litaba tsa SiC) | (Wt)% | >99 | |

| (Karolelano ea boholo ba lijo-thollo) | micron | 4-10 | |

| (Density) | kg/dm3 | >3.14 | |

| (Ho bonahala porosity) | Vo1% | <0.5 | |

| (Vickers hardness) | HV 0.5 | GPA | 28 |

| *() Flexural matla* (lintlha tse tharo) | 20ºC | MPa | 450 |

| (Matla a hatellang) | 20ºC | MPa | 3900 |

| (Modulus ea Elastic) | 20ºC | GPA | 420 |

| (Bothata ba ho robeha) | MPa/m'% | 3.5 | |

| (Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Ho hanyetsa) | 20°C | Ohm.cm | 106-108 |

(Coefficient ea ho eketsa mocheso) | a(RT**...80ºC) | K-1*10-6 | 4.3 |

(Boholo ba mocheso o sebetsang) | oºC | 1700 | |

Silicon carbide ceramic tube parameter:

| Lintho | Index |

| α-SIC | 99% mets |

| Porosity e bonahalang | 16% boholo |

| Boima ba Bongata | 2.7g/cm3 mets |

| Matla a Kobehang ka Mocheso o Phahameng | 100 Mpa mets |

| Coefficient ea Katoloso ea Thermal | K-1 4.7x10 -6 |

| Coefficient of Thermal Conductivity(1400ºC) | 24 W/mk |

| Max. Mocheso oa Mosebetsi | 1650ºC |

Lisebelisoa tsa mantlha:

1. Silicon carbide ceramic plate

- Ho itšeha le ho belisoa: e sebetsa e le sethala se behang ho netefatsa ho nepahala le botsitso bo phahameng nakong ea ho itšeha le ho bentša.

- Ts'ebetso ea Lithography: Mokotla o tsitsitse mochining oa lithography ho netefatsa boemo bo nepahetseng bo phahameng nakong ea ho pepeseha.

- Chemical Mechanical Polishing (CMP) : e sebetsa e le sethala sa ts'ehetso bakeng sa liphahlo tsa polishing, ho fana ka khatello e tšoanang le kabo ea mocheso.

2. Silicon carbide ceramic tube

- Mocheso o phahameng oa sebōpi: o sebelisoa bakeng sa lisebelisoa tsa mocheso o phahameng joalo ka sebōpi sa phallo le sebōpi sa oxidation ho jara liphaphatha bakeng sa kalafo e phahameng ea mocheso.

- Ts'ebetso ea CVD / PVD: E le tube e behang ka phaposing ea karabelo, e hanyetsanang le mocheso o phahameng le likhase tse senyang.

- Lisebelisoa tsa lisebelisoa tsa semiconductor: bakeng sa lisebelisoa tsa mocheso, liphaephe tsa khase, joalo-joalo, ho ntlafatsa ts'ebetso ea tsamaiso ea mocheso ea lisebelisoa.

XKH e fana ka mefuta e mengata ea litšebeletso tse tloaelehileng bakeng sa literei tsa silicon carbide ceramic, likopi tse monyang le li-tubes tsa silicon carbide ceramic. Li-trays tsa silicon carbide ceramic le linoelo tse monyang, XKH e ka etsoa ho latela litlhoko tsa bareki ba boholo bo fapaneng, libopeho le bohloeki ba holim'a metsi, le ho tšehetsa phekolo e khethehileng ea ho roala, ho matlafatsa ho hanyetsa le ho thibela kutu; Bakeng sa li-tubes tsa silicon carbide ceramic, XKH e ka iketsetsa mefuta e sa tšoaneng ea bophara ba ka hare, bophara ba ka ntle, bolelele le mohaho o rarahaneng (joaloka tube e bōpehileng kapa ea porous tube), le ho fana ka polishing, anti-oxidation coating le mekhoa e meng ea phekolo ea holim'a metsi. XKH e etsa bonnete ba hore bareki ba ka sebelisa melemo e feletseng ea melemo ea ts'ebetso ea lihlahisoa tsa silicon carbide ceramic ho finyella litlhoko tse boima tsa masimo a phahameng a ho etsa lihlahisoa tse kang li-semiconductors, li-leds le photovoltaics.

Setšoantšo se qaqileng