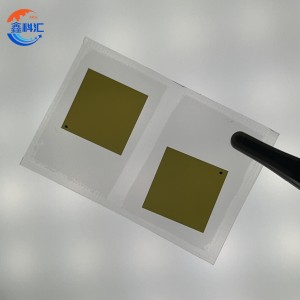

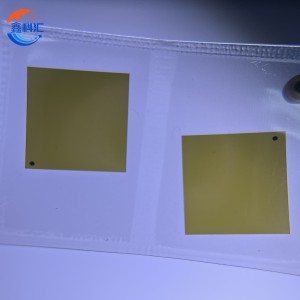

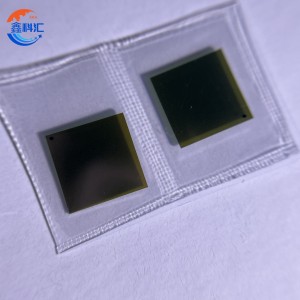

Silicon Carbide (SiC) E le 'ngoe-Crystal Substrate - 10×10mm Wafer

Setšoantšo se qaqileng sa Silicon Carbide (SiC) substrate wafer

Kakaretso ea Silicon Carbide (SiC) substrate wafer

The10 × 10mm Silicon Carbide (SiC) sephaphatha sa kristale e le 'ngoeke sesebelisoa sa semiconductor se sebetsang hantle haholo se etselitsoeng moloko o latelang oa lisebelisoa tsa motlakase tsa motlakase le lisebelisoa tsa optoelectronic. E na le conductivity e ikhethang ea mocheso, bandgap e pharaletseng, le botsitso bo botle ba lik'hemik'hale, Silicon Carbide (SiC) substrate wafer e fana ka motheo oa lisebelisoa tse sebetsang hantle tlas'a mocheso o phahameng, maqhubu a phahameng le maemo a phahameng a motlakase. Li-substrates tsena li khaotsoe ka nepo10 × 10mm lisekoere li-chips, e loketse bakeng sa lipatlisiso, prototyping, le tlhahiso ea lisebelisoa.

Molao-motheo oa Tlhahiso ea Silicon Carbide (SiC) substrate wafer

Silicon Carbide (SiC) substrate wafer e etsoa ka Physical Vapor Transport (PVT) kapa mekhoa ea kholo ea sublimation. Mokhoa ona o qala ka phofo e phahameng ea SiC e kentsoeng ka har'a crucible ea graphite. Tlas'a mocheso o feteletseng o fetang 2,000 ° C le tikoloho e laoloang, phofo e theohela ka har'a mouoane ebe e beha hape holim'a kristale ea peō e shebileng ka hloko, e etsa kristale e kholo, e nang le sekoli e fokolang e le 'ngoe ea kristale.

Hang ha SiC boule e se e hōlile, e tsoela pele:

- Ingot slicing: Lisaha tsa terata tsa daemane tsa Precision li khaola ingot ea SiC hore e be li-wafers kapa chips.

- Ho phunya le ho sila: Libaka li batalatsoa ho tlosa matšoao a sakha le ho fihlela botenya bo lekanang.

- Chemical Mechanical Polishing (CMP): E fihlella seipone se lokiselitsoeng epi se nang le mahoashe a tlase haholo.

- Doping ea boikhethelo: Nitrogen, aluminium, kapa boron doping e ka hlahisoa ho lokisa thepa ea motlakase (mofuta oa n kapa p-mofuta).

- Tlhahlobo ea boleng: Metroloji e tsoetseng pele e netefatsa ho batalla ha liphaephe, ho lekana ha botenya, le ho teteana ha sekoli ho fihlela litlhoko tse thata tsa boemo ba semiconductor.

Ts'ebetso ena ea mehato e mengata e fella ka li-chips tse matla tsa 10 × 10mm Silicon Carbide (SiC) tse seng li loketse kholo ea epitaxial kapa ho etsoa ha sesebelisoa ka kotloloho.

Litšobotsi tsa lintho tse bonahalang tsa Silicon Carbide (SiC) substrate wafer

Silicon Carbide (SiC) substrate wafer e entsoe haholo ka4H-SiC or 6H-SiCpolytypes:

-

4H-SiC:E na le motsamao o phahameng oa elektronike, e etsa hore e be e loketseng lisebelisoa tsa motlakase tse kang MOSFET le Schottky diode.

-

6H-SiC:E fana ka thepa e ikhethang bakeng sa RF le likarolo tsa optoelectronic.

Lintho tsa bohlokoa tsa 'mele tsa Silicon Carbide (SiC) substrate wafer:

-

Bandgap e pharaletseng:~ 3.26 eV (4H-SiC) - e thusa ho fokotsa matla a ho senya le ho lahleheloa ke ho fetoha ha tlaase.

-

Thermal conductivity:3-4.9 W / cm·K - e senya mocheso ka katleho, ho netefatsa botsitso tsamaisong ea matla a phahameng.

-

Ho thatafala:~ 9.2 ka tekanyo ea Mohs - e tiisa ho tšoarella ha mechine nakong ea ts'ebetso le ts'ebetso ea lisebelisoa.

Lisebelisoa tsa Silicon Carbide (SiC) substrate wafer

Ho feto-fetoha ha liphaephe tsa Silicon Carbide (SiC) ho li etsa tsa bohlokoa liindastering tse ngata:

Motlakase oa Motlakase: Motheo oa li-MOSFET, li-IGBT, le li-diode tsa Schottky tse sebelisoang likoloing tsa motlakase (EVs), phepelo ea matla a indasteri, le li-inverters tsa matla a ka nchafatsoang.

Lisebelisoa tsa RF & Microwave: E ts'ehetsa li-transistors, li-amplifiers, le likarolo tsa radar bakeng sa 5G, satellite, le lits'ebetso tsa ts'ireletso.

Optoelectronics: E sebelisoa ho li-LED tsa UV, li-photodetectors, le laser diode moo pepenene e phahameng ea UV le botsitso li leng bohlokoa.

Aerospace & Defense: Substrate e ka tšeptjoang bakeng sa mocheso o phahameng, lisebelisoa tsa elektronike tse thatafalitsoeng ke mahlaseli.

Mekhatlo ea Lipatlisiso le Liunivesithi: E loketse lithuto tsa mahlale a lintho tse bonahalang, nts'etsopele ea lisebelisoa tsa prototype, le liteko tse ncha tsa epitaxial.

Litlhaloso tsa Silicon Carbide (SiC) substrate Wafer Chips

| Thepa | Boleng |

|---|---|

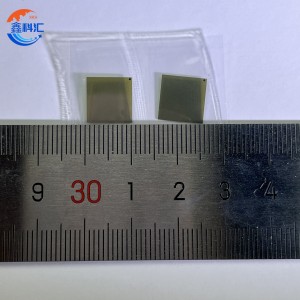

| Boholo | 10mm × 10mm lisekoere |

| Botenya | 330–500 μm (e ka tloaeleha) |

| Polytype | 4H-SiC kapa 6H-SiC |

| Boitloaelo | C-plane, off-axis (0°/4°) |

| Surface Finish | Lehlakore le le leng kapa le bentšitsoeng ka mahlakoreng a mabeli; epi-ready e fumaneha |

| Likhetho tsa Doping | Mofuta oa N kapa P-mofuta |

| Kereiti | Kereiti ea lipatlisiso kapa kereiti ea sesebelisoa |

FAQ ea Silicon Carbide (SiC) substrate wafer

Q1: Ke eng e etsang hore Silicon Carbide (SiC) substrate e phahamisitsoeng e phahametse liphaphatha tsa setso tsa silicon?

SiC e fana ka matla a 10 × a phahameng a ho senya matla, ho hanyetsa mocheso o phahameng, le tahlehelo e fokolang ea ho fetola, e leng se etsang hore e be se loketseng bakeng sa lisebelisoa tse phahameng, tse matla haholo tseo silicon e ke keng ea li tšehetsa.

Q2: Na sephaphatha sa 10 × 10mm Silicon Carbide (SiC) se ka fanoa ka likarolo tsa epitaxial?

Ee. Re fana ka li-epi-ready substrates 'me re ka fana ka li-wafers tse nang le mekhahlelo e tloaelehileng ea epitaxial ho finyella lisebelisoa tse khethehileng tsa motlakase kapa litlhoko tsa tlhahiso ea LED.

Q3: Na boholo ba tloaelo le maemo a doping a teng?

Ruri. Le ha li-chips tsa 10 × 10mm e le tse tloaelehileng bakeng sa lipatlisiso le sampole ea sesebelisoa, boholo ba tloaelo, botenya, le li-profile tsa doping li fumaneha ha u kopa.

Q4: Li-wafers tsee li tšoarella hakae maemong a feteletseng?

SiC e boloka botšepehi ba sebopeho le ts'ebetso ea motlakase ka holimo ho 600 ° C le tlas'a mahlaseli a phahameng, e leng se etsang hore e be se loketseng bakeng sa lisebelisoa tsa elektronike tsa boemo ba sesole.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.