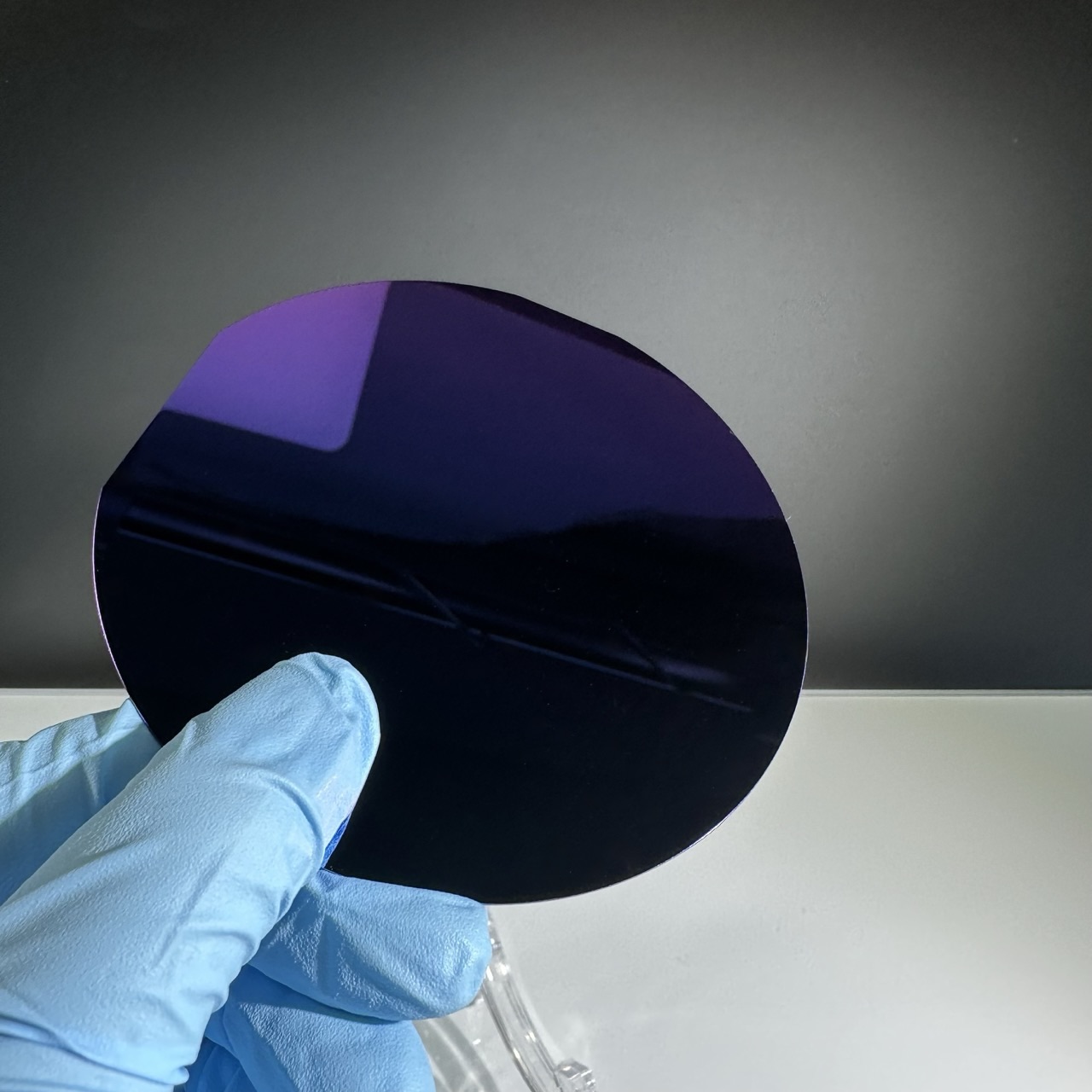

Sephaephe sa Silicon Dioxide sa SiO2 se tenya se hloekisitsoeng, se phahameng le sa Tlhahlobo

Hlahisa lebokose la wafer

| Sehlahisoa | Li-wafers tsa Thermal Oxide (Si+SiO2). |

| Mokhoa oa Tlhahiso | LPCVD |

| Ho benya ha Bokaholimo | SSP/DSP |

| Diameter | 2inch/3inch/4inch/5inch/6inch |

| Mofuta | Mofuta oa P / N |

| Botenya ba Lera la Oxidation | 100nm ~ 1000nm |

| Boitloaelo | <100> <111> |

| Restivity ea motlakase | 0.001-25000(Ω•cm) |

| Kopo | E sebelisetsoa ho tsamaisa sampole ea mahlaseli a synchrotron, ho roala ha PVD/CVD joalo ka substrate, sampole ea kholo ea magnetron sputtering, XRD, SEM,Matla a atomic, spectroscopy ea infrared, fluorescence spectroscopy le likaroloana tse ling tsa tlhahlobo ea tlhahlobo, li-molecular beam epitaxial growth substrates, tlhahlobo ea X-ray ea crystalline semiconductors. |

Li-wafers tsa Silicon oxide ke lifilimi tsa silicon dioxide tse hōlileng holim'a liphaphatha tsa silicon ka ho sebelisa oksijene kapa mouoane oa metsi mochesong o phahameng (800 ° C ~ 1150 ° C) ho sebelisoa mokhoa oa ho futhumatsa oxidation ka thepa ea sebōpi sa khatello ea sepakapaka. Botenya ba ts'ebetso bo tloha ho li-nanometers tse 50 ho isa ho li-microns tse 2, mocheso oa ts'ebetso o fihla ho likhato tse 1100 tsa Celsius, mokhoa oa ho hōla o arotsoe ka "oksijene e metsi" le "oksijene e omileng" mefuta e 'meli. Thermal Oxide ke "khōlō" ea oxide layer, e nang le ho tšoana ho holimo, ho teteana ho molemo le matla a phahameng a dielectric ho feta CVD deposited layers oxide, e hlahisang boleng bo holimo.

Oxygen Oxidation e omileng

Silicon e sebetsana le oksijene 'me lesela la oxide le lula le lebile ho substrate layer. Oxidation e omileng e hloka ho etsoa ka mocheso ho tloha ho 850 ho isa ho 1200 ° C, ka sekhahla sa kholo e tlase, 'me e ka sebelisoa bakeng sa kholo ea heke e sirelelitsoeng ea MOS. Oxidation e ommeng e ratoa ho feta ea oxidation e metsi ha ho hlokahala lesela la boleng bo holimo, le tšesaane haholo la silicon. Matla a oxidation a omileng: 15nm ~ 300nm.

2. Metsi a Oxidation

Mokhoa ona o sebelisa mouoane oa metsi ho etsa lera la oxide ka ho kenya tube ea sebōpi tlas'a maemo a phahameng a mocheso. The densification ea metsi oksijene oxidation e mpe hanyenyane ho feta oksijene e omeletseng ea oksijene, empa ha e bapisoa le oxidation e omeletseng ea oksijene molemo oa eona ke hore e na le sekhahla se phahameng sa khōlo, se loketseng ho feta khōlo ea filimi ea 500nm. Bokhoni ba oxidation ea metsi: 500nm ~ 2µm.

AEMD's atmospheric pressure oxidation furnace tube ke sebopi sa Czech se otlolohileng, se khetholloang ka botsitso bo phahameng ba ts'ebetso, ho tšoana hantle ha filimi le taolo e phahameng ea likaroloana. Thepa ea silicon oxide sebōpi e ka sebetsa ho fihla ho li-wafers tse 50 ka tube ka 'ngoe, e nang le ts'ebetso e ntle ea intra- le inter-wafers.

Setšoantšo se qaqileng