SiO₂ Quartz Wafer Quartz Wafers SiO₂ MEMS Mocheso 2″ 3″ 4″ 6″ 8″ 12″

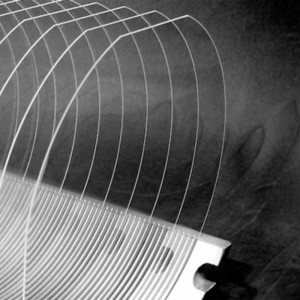

Setšoantšo se qaqileng

Selelekela

Li-wafer tsa quartz li bapala karolo ea bohlokoa ho nts'etsopele ea indasteri ea elektroniki, ea semiconductor le ea optics. E fumanoa ho li-smartphones tse tataisang GPS ea hau, tse kentsoeng liteisheneng tse phahameng tsa maqhubu tse matlafatsang marang-rang a 5G, 'me li kopantsoe le lisebelisoa tse etsang li-microchip tsa mofuta o latelang, li-wafer tsa quartz lia hlokahala. Li-substrates tsena tse nang le bohloeki bo phahameng li thusa ho nchafatsa ntho e 'ngoe le e 'ngoe ho tloha ho quantum computing ho ea ho photonics e tsoetseng pele. Leha a nkiloe ho e 'ngoe ea liminerale tse ngata ka ho fetesisa Lefatšeng, li-wafer tsa quartz li entsoe ka maemo a makatsang a ho nepahala le ts'ebetso.

Li-Wafers tsa Quartz ke eng

Li-wafers tsa quartz ke li-disc tse tšesaane, tse chitja tse entsoeng ka kristale ea quartz e hloekileng haholo. E fumaneha ka li-diameter tse tloaelehileng ho tloha ho 2 ho isa ho 12 inches, li-wafers tsa quartz hangata li fapana ka botenya ho tloha ho 0.5 mm ho ea ho 6 mm. Ho fapana le quartz ea tlhaho, e etsang likristale tse sa tloaelehang tsa prismatic, quartz ea maiketsetso e holisoa tlasa maemo a lab a laoloang ka thata, e hlahisa meaho e ts'oanang ea kristale.

Bokhabane ba tlhaho ba li-wafers tsa quartz bo fana ka khanyetso ea lik'hemik'hale e ke keng ea lekanngoa, pepeneneng ea optical, le botsitso tlas'a mocheso o phahameng le khatello ea mochine. Likarolo tsena li etsa hore li-wafers tsa quartz e be karolo ea motheo bakeng sa lisebelisoa tse nepahetseng tse sebelisoang phetisong ea data, sensing, computation, le theknoloji e thehiloeng ho laser.

Litlhaloso tsa Quartz Wafer

| Mofuta oa Quartz | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Boholo | ||||

| Diameter (inch) | 4 | 6 | 8 | 12 |

| Botenya (mm) | 0.05–2 | 0.25–5 | 0.3–5 | 0.4–5 |

| Mamello ea Diameter (inch) | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Mamello ea Botenya (mm) | Customizable | Customizable | Customizable | Customizable |

| Thepa ea Optical | ||||

| Refractive Index @365 nm | 1.474698 | 1.474698 | 1.474698 | 1.474698 |

| Refractive Index @546.1 nm | 1.460243 | 1.460243 | 1.460243 | 1.460243 |

| Refractive Index @1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| Phetiso ea ka Hare (1250–1650 nm) | >99.9% | >99.9% | >99.9% | >99.9% |

| Kakaretso ea Phetiso (1250–1650 nm) | >92% | >92% | >92% | >92% |

| Boleng ba ho sebetsa | ||||

| TTV (Total Thickness Variation, µm) | <3 | <3 | <3 | <3 |

| Bophahamo (µm) | ≤15 | ≤15 | ≤15 | ≤15 |

| Bokhopo ba Sekaho (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Bow (µm) | <5 | <5 | <5 | <5 |

| Thepa ea 'Mele | ||||

| Boima ba 'mele (g/cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| Young's Modulus (GPA) | 74.20 | 74.20 | 74.20 | 74.20 |

| Mohs Hardness | 6–7 | 6–7 | 6–7 | 6–7 |

| Shear Modulus (GPA) | 31.22 | 31.22 | 31.22 | 31.22 |

| Karolelano ea Poisson | 0.17 | 0.17 | 0.17 | 0.17 |

| Compressive Strength (GPA) | 1.13 | 1.13 | 1.13 | 1.13 |

| Tensile Strength (MPa) | 49 | 49 | 49 | 49 |

| Dielectric Constant (1 MHz) | 3.75 | 3.75 | 3.75 | 3.75 |

| Thermal Properties | ||||

| Strain Point (10¹⁴.⁵ Pa·s) | 1000°C | 1000°C | 1000°C | 1000°C |

| Annealing Point (10¹³ Pa·s) | 1160°C | 1160°C | 1160°C | 1160°C |

| Bonolo (10⁷.⁶ Pa·s) | 1620°C | 1620°C | 1620°C | 1620°C |

Lisebelisoa tsa Quartz Wafers

Li-wafer tsa quartz li entsoe ka tloaelo ho kopana le lits'ebetso tse hlokang liindasteri ho kenyelletsa:

Lisebelisoa tsa elektroniki le tsa RF

- Li-wafer tsa quartz ke tsa mantlha ho li-quartz crystal resonator le li-oscillator tse fanang ka matšoao a oache bakeng sa li-smartphones, likarolo tsa GPS, likhomphutha le lisebelisoa tsa puisano tse se nang mohala.

- Katoloso ea bona e tlase ea mocheso le Q-factor e phahameng li etsa hore li-wafers tsa quartz li phethahale bakeng sa li-circuits tsa nako tse tsitsitseng le li-filters tsa RF.

Optoelectronics le litšoantšo

- Li-wafer tsa quartz li fana ka phetisetso e ntle ea UV le IR, e li etsang hore e be tse loketseng lilense tsa mahlo, li-splitter, lifensetere tsa laser le li-detectors.

- Ho hanyetsa ha bona mahlaseli a kotsi ho etsa hore ho sebelisoe fisiks e matla le lisebelisoa tsa sebaka.

Semiconductor le MEMS

- Li-wafer tsa quartz li sebetsa e le likaroloana tsa li-circuits tsa semiconductor tse phahameng haholo, haholo lits'ebetsong tsa GaN le RF.

- Ho MEMS (Micro-Electro-Mechanical Systems), li-wafers tsa quartz li fetolela matšoao a mochini hore e be a motlakase ka phello ea piezoelectric, e nolofalletsang li-sensor tse kang gyroscopes le accelerometers.

Tlhahiso e tsoetseng pele le Labs

- Li-wafer tsa quartz tse hloekileng haholo li sebelisoa haholo ho li-labs tsa lik'hemik'hale, tsa biomedical le tsa photonic bakeng sa lisele tsa mahlo, li-cuvettes tsa UV, le ho tšoara sampole ea mocheso o phahameng.

- Ho lumellana ha tsona le libaka tse feteletseng ho li etsa hore li tšoanele likamore tsa plasma le lisebelisoa tsa ho beha.

Kamoo Li-Wafers tsa Quartz li Etsoang Kateng

Ho na le litsela tse peli tsa mantlha tsa tlhahiso ea li-wafers tsa quartz:

Li-Wafers tsa Quartz tse Fuselitsoeng

Li-wafers tsa quartz tse kopantsoeng li entsoe ka ho qhibilihisa li-granules tsa tlhaho tsa quartz ka khalase ea amorphous, ebe e seha le ho bentša boloko bo tiileng hore e be liphaphatha tse tšesaane. Li-wafers tsena tsa quartz li fana ka:

- Ponaletso e ikhethang ea UV

- Sebaka se pharaletseng sa tšebetso ea mocheso (> 1100°C)

- E babatsehang ho hanyetsa mocheso oa mocheso

Li loketse lisebelisoa tsa lithography, libōpi tsa mocheso o phahameng, le lifensetere tsa optical empa ha li tšoanelehe bakeng sa lisebelisoa tsa piezoelectric ka lebaka la ho hloka taelo ea kristale.

Li-Wafers tsa Quartz tse hlophisitsoeng

Li-wafers tsa quartz tse hlahisitsoeng li lengoa ka mokhoa oa maiketsetso ho hlahisa likristale tse se nang sekoli tse nang le sebopeho se nepahetseng sa lattice. Li-wafers tsena li etselitsoe lisebelisoa tse hlokang:

- Li-angles tse sehiloeng hantle (X-, Y-, Z-, AT-cut, joalo-joalo)

- Li-oscillator tsa maqhubu a phahameng le li-filters tsa SAW

- Optical polarizers le lisebelisoa tse tsoetseng pele tsa MEMS

Ts'ebetso ea tlhahiso e kenyelletsa kholo ea peo ka har'a li-autoclave, 'me e lateloe ke ho seha, ho lebisoa, ho fafatsa le ho bentša.

Ea etellang pele Quartz Wafer Suppliers

Barekisi ba lefats'e ba sebetsanang le li-wafers tsa quartz tse nepahetseng haholo ba kenyelletsa:

- Heraeus(Jeremane) - quartz e kopantsoeng le ea maiketsetso

- Shin-Etsu Quartz(Japan) - litharollo tse phahameng tsa sephaphatha

- WaferPro(USA) - li-wafers tsa quartz tse bophara ba bophara le li-substrates

- Korth Kristalle(Jeremane) - liphaphatha tsa kristale tsa maiketsetso

Karolo e Fetohang ea Li-Wafers tsa Quartz

Li-wafer tsa quartz li ntse li tsoela pele ho fetoha e le likarolo tsa bohlokoa libakeng tse ntseng li hlaha tsa theknoloji:

- Miniaturization- Li-wafer tsa quartz li ntse li etsoa ka mamello e matla bakeng sa ho kopanya lisebelisoa tse kopanetsoeng.

- Maqhubu a Elektronike a Phahameng- Meetso e mecha ea quartz wafer e ntse e kenella libakeng tsa mmWave le THz bakeng sa 6G le radar.

- Next-Gen Sensing- Ho tloha likoloing tse ikemetseng ho ea ho IoT ea indasteri, li-sensor tse thehiloeng ho quartz li fetoha tsa bohlokoa le ho feta.

Lipotso tse botsoang khafetsa mabapi le li-wafers tsa quartz

1. Sephaphatha sa quartz ke eng?

Sephaphatha sa quartz ke disc e tšesaane, e bataletseng e entsoeng ka crystalline silicon dioxide (SiO₂), eo hangata e entsoeng ka boholo bo tloaelehileng ba semiconductor (mohlala, 2", 3", 4", 6", 8", kapa 12 "). E tsebahala ka bohloeki ba eona bo phahameng, botsitso ba mocheso, le ho pepeseha ha optical, sephaphatha sa quartz se sebelisoa e le substrate kapa sejari lits'ebetsong tse fapaneng tse nepahetseng tse kang semiconductor fabrication, lisebelisoa tsa MEMS, optical systems le vacuum systems.

2. Phapang ke efe pakeng tsa quartz le silica gel?

Quartz ke mofuta o tiileng oa crystalline oa silicon dioxide (SiO₂), ha gel ea silica e le mofuta oa amorphous le porous oa SiO₂, o atisang ho sebelisoa e le desiccant ho monya mongobo.

- Quartz e thata, e pepenene ebile e sebelisoa lits'ebetsong tsa elektroniki, tsa mahlo le tsa indasteri.

- Silika gel e hlaha e le lifaha tse nyane kapa granules mme e sebelisoa haholo ho laola mongobo ka har'a liphutheloana, lisebelisoa tsa elektroniki le polokelo.

3. Likristale tsa quartz li sebelisetsoa eng?

Likristale tsa Quartz li sebelisoa haholo ho elektronike le optics ka lebaka la thepa ea tsona ea piezoelectric (li hlahisa tefiso ea motlakase tlas'a khatello ea mochine). Lisebelisoa tse tloaelehileng li kenyelletsa:

- Li-oscillator le taolo ea maqhubu(mohlala, lioache tsa quartz, lioache, li-microcontroller)

- Likarolo tsa Optical(mohlala, lilense, li-waveplates, lifensetere)

- Li-resonator le li-filterska RF le lisebelisoa tsa puisano

- Li-sensorbakeng sa kgatello, ho potlakisa, kapa matla

- Tlhahiso ea semiconductorjoalo ka li-substrates kapa lifensetere tsa tšebetso

4. Ke hobane'ng ha quartz e sebelisoa li-microchips?

Quartz e sebelisoa lits'ebetsong tse amanang le microchip hobane e fana ka:

- Ho tsitsa ha mochesonakong ea ts'ebetso ea mocheso o phahameng joalo ka ho hasana le ho annealing

- Tšireletso ea motlakaseka lebaka la thepa ea eona ea dielectric

- Ho hanyetsa lik'hemik'haleho li-acids le li-solvents tse sebelisoang ha ho etsoa semiconductor

- Ho nepahala ha dimensionalle katoloso e tlase ea mocheso bakeng sa ho tsamaisana le lithography e tšepahalang

- Le hoja quartz ka boeona e sa sebelisoe e le lisebelisoa tse sebetsang tsa semiconductor (joaloka silicon), e bapala karolo ea bohlokoa ea ts'ehetso tikolohong ea masela-haholo-holo liboping, likamoreng le li-substrates tsa photomask.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.