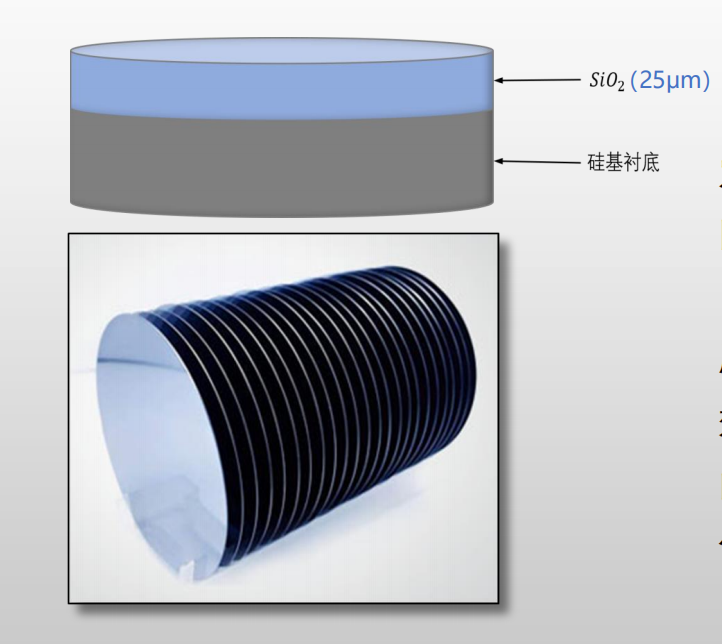

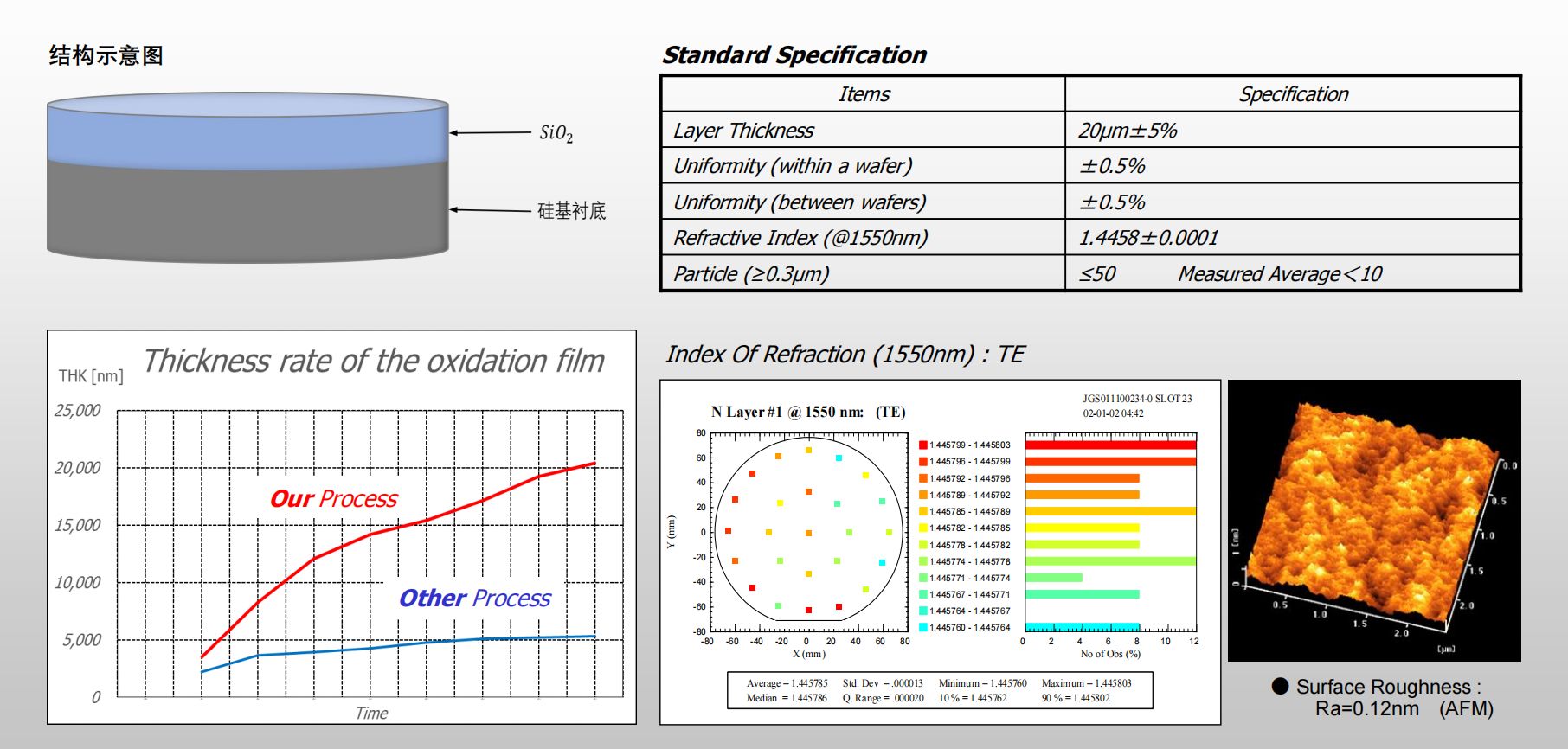

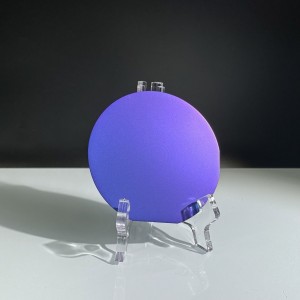

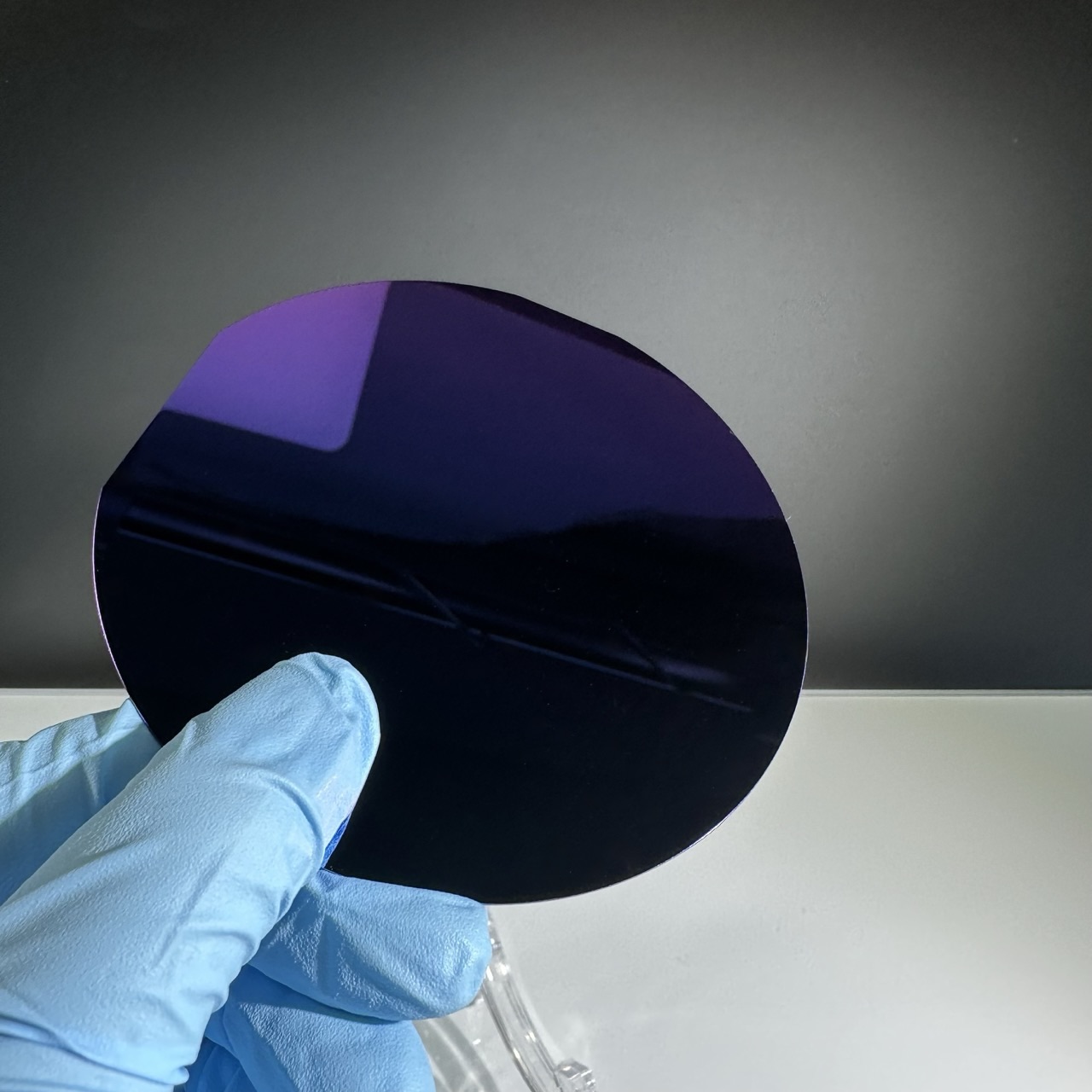

SiO2 Thin Film Thermal Oxide Silicon wafer 4inch 6inch 8inch 12inch

Hlahisa lebokose la wafer

Mokhoa o ka sehloohong oa ho etsa li-wafers tsa silicon tse nang le oxidized hangata o kenyelletsa mehato e latelang: kholo ea silicon ea monocrystalline, ho itšeha ka li-wafers, polishing, hloekisa le oxidation.

Khōlo ea silicon ea monocrystalline: Ntlha ea pele, silicon ea monocrystalline e lengoa ka mocheso o phahameng ka mekhoa e kang mokhoa oa Czochralski kapa mokhoa oa Float-zone. Mokhoa ona o nolofalletsa ho lokisoa ha likristale tse le 'ngoe tsa silicon tse nang le bohloeki bo phahameng le botšepehi ba lesela.

Dicing: Silicone e ntseng e hola ea monocrystalline hangata e na le sebopeho sa cylindrical mme e hloka ho khaoloa hore e be liphaphatha tse tšesaane hore li sebelisoe joalo ka sephaphatha. Ho khaola hangata ho etsoa ka sehahi sa taemane.

Ho pholisa: Bokaholimo ba sephaphatha se sehiloeng bo ka 'na ba se lekane 'me bo hloka ho belisoa ka lik'hemik'hale ho fumana bokaholimo bo boreleli.

Ho hloekisa: Sephaphatha se bentšitsoeng se hloekisoa ho tlosa litšila le lerōle.

Oxidizing: Qetellong, liphaphatha tsa silicon li kenngoa ka sebōping sa mocheso o phahameng oa mocheso bakeng sa phekolo ea oxidizing ho etsa lera le sireletsang la silicon dioxide ho ntlafatsa thepa ea eona ea motlakase le matla a mochine, hammoho le ho sebetsa e le lera le sireletsang lipotolohong tse kopantsoeng.

Tšebeliso e ka sehloohong ea li-wafers tsa silicon tse nang le oxidized li kenyelletsa ho etsa lipotoloho tse kopantsoeng, ho etsoa ha lisele tsa letsatsi, le ho etsa lisebelisoa tse ling tsa elektroniki. Li-wafers tsa silicon oxide li sebelisoa haholo tšimong ea lisebelisoa tsa semiconductor ka lebaka la thepa ea tsona e ntle ea mechine, botsitso ba dimensional le lik'hemik'hale, bokhoni ba ho sebetsa ka mocheso o phahameng le likhatello tse phahameng, hammoho le thepa e ntle ea insulating le optical.

Melemo ea eona e kenyelletsa sebopeho se feletseng sa kristale, motsoako o hloekileng oa lik'hemik'hale, litekanyo tse nepahetseng, lisebelisoa tse ntle tsa mechine, joalo-joalo Likarolo tsena li etsa hore li-wafers tsa silicon oxide li tšoanelehe ka ho khetheha bakeng sa ho etsa lipotoloho tse kopantsoeng tse sebetsang hantle le lisebelisoa tse ling tsa microelectronic.

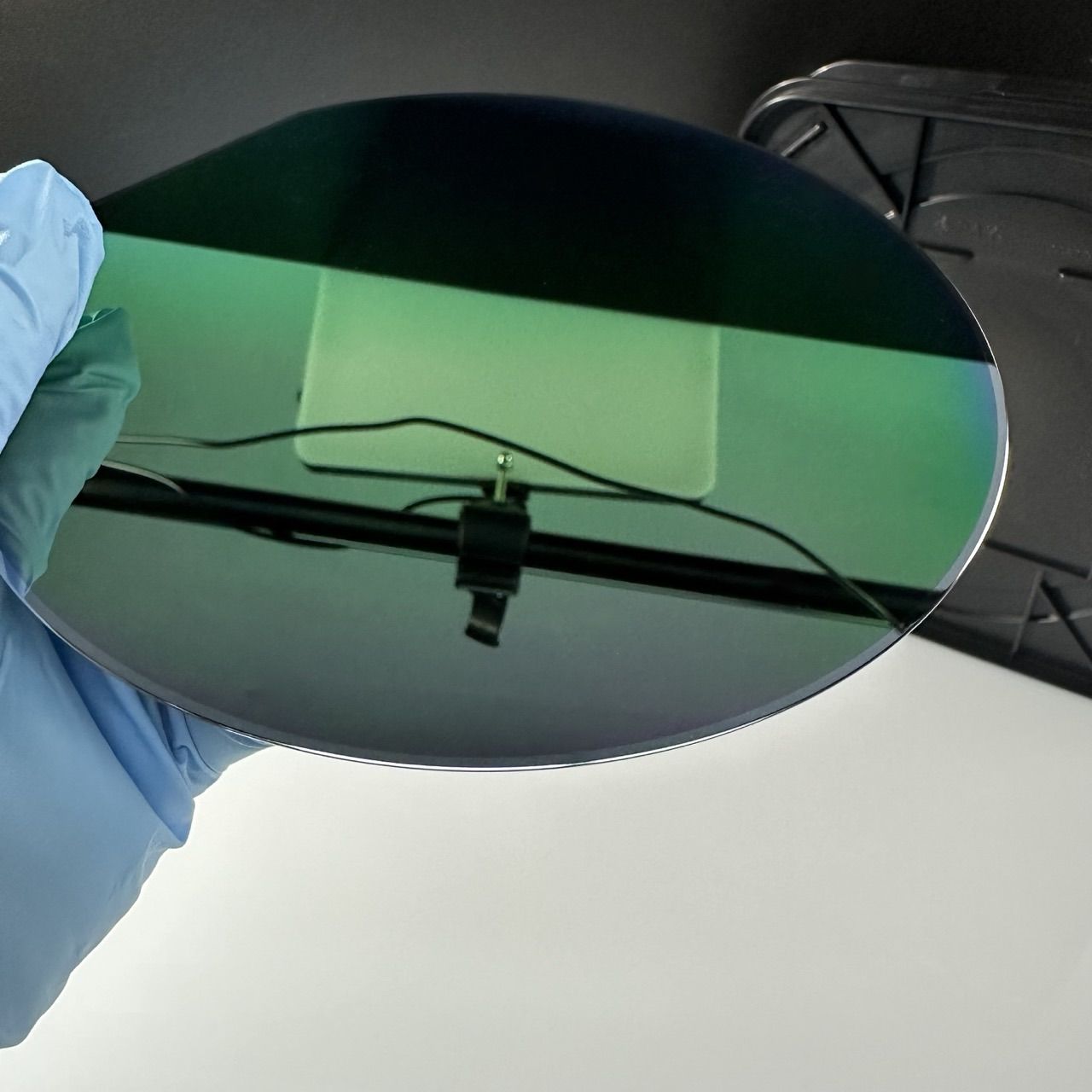

Setšoantšo se qaqileng