Tafole e nyane ea laser punching mochini 1000W-6000W bonyane aperture 0.1MM e ka sebelisoa bakeng sa lisebelisoa tsa tšepe tsa khalase tsa ceramic.

Lisebelisoa tse sebetsang

1. Lisebelisoa tsa tšepe: tse kang aluminium, koporo, alloy ea titanium, tšepe e sa hloekang, joalo-joalo.

2. Lisebelisoa tse se nang tšepe: tse kang polasetiki (ho kenyeletsoa polyethylene PE, polypropylene PP, polyester PET le lifilimi tse ling tsa polasetiki), khalase (ho kenyeletsoa khalase e tloaelehileng, khalase e khethehileng e kang khalase e tšoeu ea ultra-white, khalase ea K9, khalase e phahameng ea borosilicate, khalase ea quartz, joalo-joalo, empa khalase e halefileng ka lebaka la thepa ea eona e khethehileng, 'mele oa ho phunya le pampiri ha o sa tšoanelehe bakeng sa thepa ea eona ea 'mele, ho phunya lesela la ceramic ka lebaka la thepa ea eona e khethehileng le pampiri ea ho phunya. ho.

3. Thepa e kopantsoeng: e entsoe ka lisebelisoa tse peli kapa ho feta tse nang le thepa e fapaneng ka mekhoa ea 'mele kapa ea lik'hemik'hale, e nang le thepa e phethahetseng.

4.Lisebelisoa tse khethehileng: Libakeng tse khethehileng, mechine ea laser punching e ka boela ea sebelisoa ho sebetsana le lisebelisoa tse khethehileng.

Litlhaloso tsa paramente

| Lebitso | Lintlha |

| Matla a Laser: | 1000W-6000W |

| Ho seha ho nepahala: | ±0.03MM |

| Botlaaseng ba aperture: | 0.1MM |

| Bolelele ba ho seha: | 650MM×800MM |

| Ho nepahala ha maemo: | ≤±0.008MM |

| Ho nepahala ho phetoa: | 0.008MM |

| Ho khaola khase: | Moea |

| Mohlala o tsitsitseng: | Pneumatic edge clamping, tšehetso ea fixture |

| Sistimi ea ho khanna: | Magnetic suspension linear motor |

| Ho khaola botenya | 0.01MM-3MM |

Melemo ea tekheniki

1.Ho cheka ka mokhoa o nepahetseng: Tšebeliso ea mahlaseli a laser a matla a matla bakeng sa ts'ebetso e sa amaneng le batho, ka potlako, motsotsoana oa 1 ho qeta ho sebetsa ha likoti tse nyenyane.

2.Ho nepahala ho phahameng: Ka ho laola ka mokhoa o nepahetseng matla, maqhubu a pulse le boemo bo lebisang tlhokomelo ea laser, ts'ebetso ea ho phunya ka ho nepahala ha micron e ka finyelloa.

3. E sebetsa ka ho pharaletseng: e ka sebetsana le mefuta e sa tšoaneng ea brittle, e thata ho sebetsa le lisebelisoa tse khethehileng, tse kang polasetiki, rabara, tšepe (tšepe e sa hloekang, aluminium, koporo, alloy ea titanium, joalo-joalo), khalase, li-ceramics joalo-joalo.

4. Ts'ebetso e bohlale: Mochini oa laser punching o na le tsamaiso e tsoetseng pele ea ho laola lipalo, e bohlale haholo ebile e bonolo ho e kopanya le moralo o thusoang ke k'homphieutha le tsamaiso ea tlhahiso ea k'homphieutha ho hlokomela lenaneo le potlakileng le ho ntlafatsa tsela e rarahaneng ea ho feta le ho sebetsa.

Maemo a mosebetsi

1.Diversity: e ka etsa mefuta e fapaneng ea ts'ebetso ea lesoba la sebopeho se rarahaneng, joalo ka masoba a chitja, masoba a lisekoere, masoba a likhutlo li tharo le masoba a mang a sebopeho se ikhethileng.

2.Boleng bo phahameng: Boleng ba sekoti bo phahame, moeli o boreleli, ha o na maikutlo a mabe, 'me deformation e nyenyane.

3.Automation: E ka phethela ts'ebetso ea micro-hole ka boholo bo lekanang ba aperture le kabo ea junifomo ka nako e le 'ngoe,' me e tšehetsa ts'ebetso ea lesoba la sehlopha ntle le ho kenella ka letsoho.

Likarolo tsa lisebelisoa

■ Boholo bo nyane ba lisebelisoa, ho rarolla bothata ba sebaka se moqotetsane.

■ Ho nepahala ho phahameng, sekoti se phahameng se ka fihla ho 0.005mm.

■ Thepa e sebetsa habonolo ebile e bonolo ho e sebelisa.

■ Mohloli oa leseli o ka nkeloa sebaka ho ea ka lisebelisoa tse fapaneng, 'me ho lumellana ho matlafala.

■ Sebaka se senyane se anngoeng ke mocheso, se na le oxidation e nyane ho potoloha masoba.

Sebaka sa kopo

1. Indasteri ea elektronike

● Printed Circuit Board (PCB) ho otla:

Microhole machining: E sebelisoa bakeng sa ho lokisa li-microholes tse bophara bo ka tlase ho 0.1mm ho PCBS ho fihlela litlhoko tsa liboto tsa high-density interconnect (HDI).

Likoti tse foufetseng le tse patiloeng: Ho sebetsa likoti tse foufetseng le tse patiloeng ka har'a PCBS tse ngata ho ntlafatsa ts'ebetso le kopanyo ea boto.

● Sephutheloana sa semiconductor:

Ho cheka foreimi e etellang pele: Likoti tse nepahetseng li entsoe ka foreimi e etellang pele ea semiconductor bakeng sa ho hokahanya chip ho potoloho ea kantle.

Wafer cutting aid: Phunya masoba ka har'a sephaphatha ho thusa lits'ebetsong tse latelang tsa ho seha le ho paka.

2. Mechini e nepahetseng

● Ho sebetsa ka likarolo tse nyane:

Ho cheka lisebelisuoa tse nepahetseng: Ho cheka masoba a phahameng ka ho fetesisa holim'a likere tse nyane bakeng sa sistimi ea phetisetso e nepahetseng.

Ho cheka karolo ea sensor: Ho etsa li-microholes ho likarolo tsa sensor ho ntlafatsa kutlo le lebelo la karabo ea kutlo.

●Mould Manufacturing:

Sekoti se futhumatsang hlobo: Ho lokisa lesoba le pholileng holim'a hlobo ea ente kapa hlobo ea ho lahla mocheso ho ntlafatsa ts'ebetso ea ho qhala mocheso oa hlobo.

Ts'ebetso ea Vent: Ho lokisa masoba a manyane holim'a hlobo ho fokotsa mefokolo.

3. Lisebelisoa tsa bongaka

●Lisebelisoa tsa ho Buoa tse sa hlaselehang habonolo:

Catheter perforation: Li-microholes li sebetsoa ka har'a li-catheter tsa opereishene tse hlaselang haholo bakeng sa ho fana ka lithethefatsi kapa ho ntša metsi.

Likarolo tsa Endoscope: Likoti tse nepahetseng li entsoe ka lense kapa hlooho ea sesebelisoa ea endoscope ho ntlafatsa ts'ebetso ea sesebelisoa.

●Sistimi ea ho fana ka lithethefatsi:

Microneedle array drilling: Ho cheka li-microholes holim'a patch ea lithethefatsi kapa li-microneedle array ho laola sekhahla sa ho lokolloa ha lithethefatsi.

Ho cheka li-biochip: Li-microholes li sebetsoa ho li-biochips bakeng sa setso sa lisele kapa ho lemoha.

4. Lisebelisoa tsa Optical

● Sehokelo sa Fiber optic:

Ho cheka lesoba la optical fiber: Ho cheka li-microholes sefahlehong sa ho qetela sa sehokelo sa optical ho ntlafatsa katleho ea phetiso ea lets'oao la optical.

Fiber array machining: Ho lokisa masoba a nepahetseng haholo holim'a poleiti ea fiber array bakeng sa puisano ea likanale tse ngata.

●Sesefa sa Optical:

Filter drilling: Ho cheka li-microholes holim'a filthara ea optical ho fihlela khetho ea maqhubu a ikhethang.

Diffractive element machining: Ho cheka li-microholes holim'a lintho tse fapaneng tsa mahlo bakeng sa ho petsoha kapa ho bōptjoa ha lebone la laser.

5. Ho etsa likoloi

●Sistimi ea ente ea mafura:

Ho phunya nozzle ea ente: Ho sebetsa likoti tse nyane ka har'a molomo oa ente ho ntlafatsa phello ea athomo ea mafura le ho ntlafatsa ts'ebetso ea ho tuka.

●Moetso oa sensor:

Ho phunya sensor ea khatello: Ho sebetsa li-microholes ho diaphragm ea sensor ea khatello ho ntlafatsa kutlo le ho nepahala ha kutlo.

●Betri e matla:

Ho chekoa ha betri poleiti: Ho cheka li-microholes ho lithium betri pole chips ho ntlafatsa ho kenella ha electrolyte le lipalangoang tsa ion.

XKH e fana ka mefuta e mengata ea lits'ebeletso tsa setopong se le seng bakeng sa li-perforators tse nyane tsa litafole, ho kenyeletsoa empa ho sa felle feela ho: Boeletsi ba thekiso ea profeshenale, moralo o hlophisitsoeng oa lenaneo, phepelo ea lisebelisoa tsa boleng bo holimo, ts'ebetso e ntle ea ts'ebetso, koetliso e felletseng ea ts'ebetso, ho netefatsa hore bareki ba fumana boiphihlelo bo nepahetseng ka ho fetesisa, bo nepahetseng le bo sa tsotelleng ts'ebetsong ea ho otla.

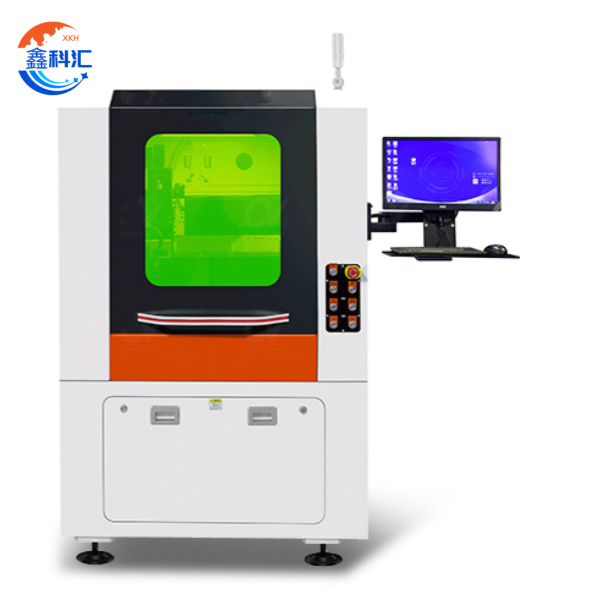

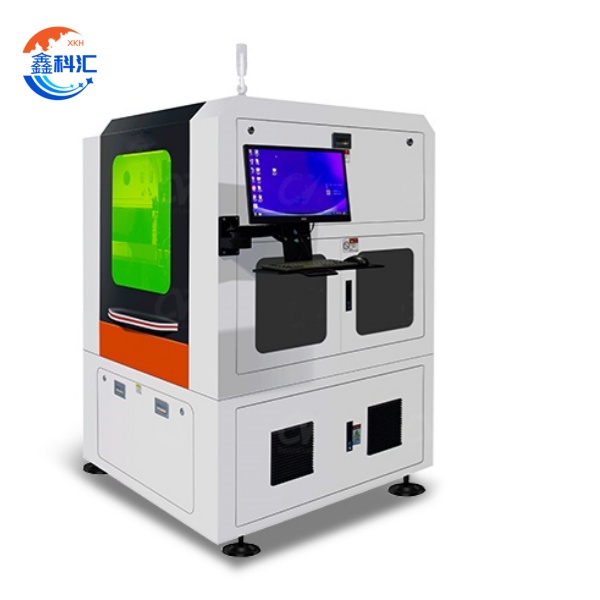

Setšoantšo se qaqileng