Soda-Lime Glass Substrates – E Nepisitsoe ka nepo ebile e na le Litšenyehelo Bakeng sa Indasteri ea Rona.

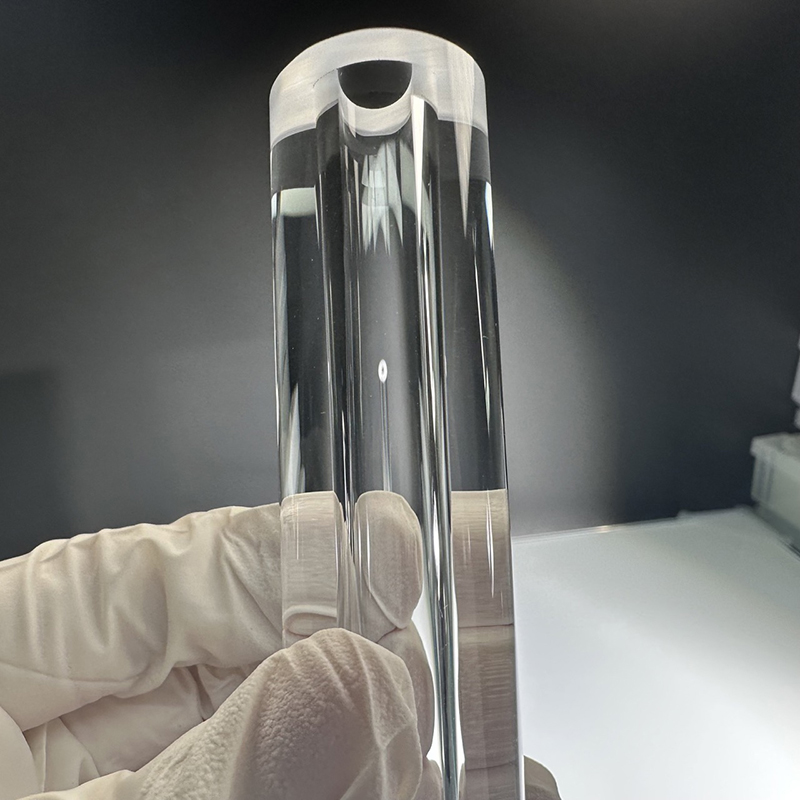

Setšoantšo se qaqileng

Kakaretso ea Khalase ea Quartz

Soda-lime substrateske likhalase tse nepahetseng tsa khalase tse entsoeng ka khalase ea silicate ea boleng bo holimo ea soda-lime - thepa e feto-fetohang le e theko e tlaase e sebelisoang haholo indastering ea optical, electronic and coating. E tsebahala ka phetisetso ea eona e ntle ea khanya, boleng ba holim'a sephara, le botsitso ba mochini, khalase ea soda-kalaka e fana ka motheo o tšepahalang bakeng sa ho beha lifilimi tse tšesaane tse fapaneng, photolithography le lits'ebetso tsa laboratori.

Ts'ebetso ea eona e leka-lekaneng ea 'mele le ea optical e etsa hore e be khetho e sebetsang bakeng sa R&D le tikoloho ea tlhahiso ea molumo.

Lintlha tsa Bohlokoa le Melemo

-

Ho Hlakola ho Hoholo ha Optical:Phetiso e ikhethang ka bongata bo bonahalang (400-800 nm), e loketseng tlhahlobo ea mahlo le litšoantšo.

-

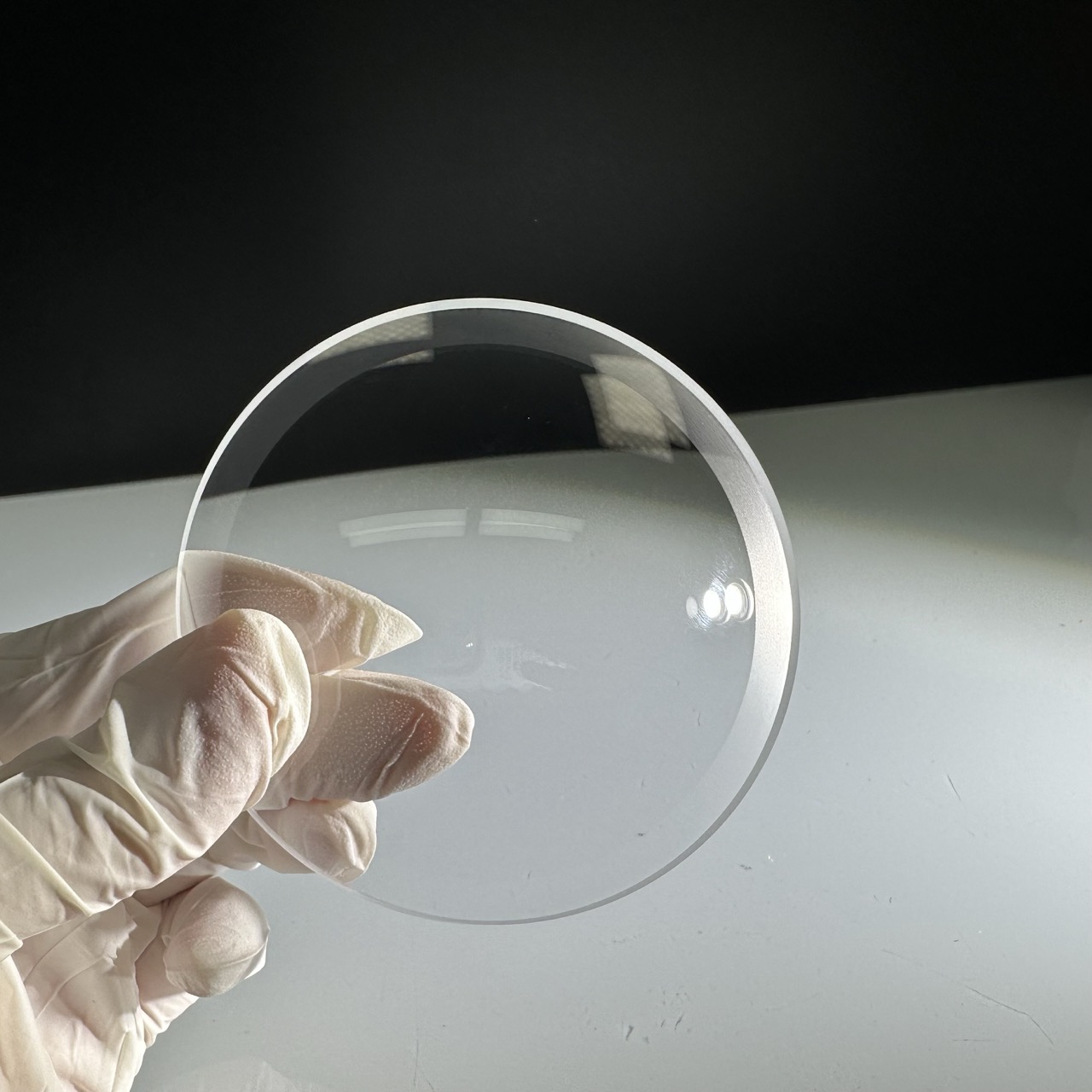

Sebaka se Boreleli se Boreleli:Mahlakore ka bobeli a ka belisoa ka mokhoa o khabane ho fihlela boima bo tlase ba holim'a metsi (<2 nm), ho etsa bonnete ba hore ho khomarela hantle bakeng sa liphahlo.

-

Dimensional Stability:E boloka ho bata le ho bapisa ho ts'oanang, ho tsamaellana le tlhophiso e nepahetseng le litlhophiso tsa metrology.

-

Thepa e Kholofatsang Litšenyehelo:E fana ka mefuta e meng e theko e tlase ho li-borosilicate kapa li-silica tse kopantsoeng bakeng sa lisebelisoa tse tloaelehileng tsa mocheso.

-

Boikemisetso:E khaotsoe habonolo, e chekiloe, kapa e entsoe ka sebopeho bakeng sa meralo e ikhethileng ea optical le elektroniki.

-

Tšebelisano ea Lik'hemik'hale:E lumellana le li-photoresists, li-adhesive, le lisebelisoa tse ngata tse tšesaane tsa ho beha lifilimi (ITO, SiO₂, Al, Au).

Ka motsoako oa eona oa ho hlaka, matla le ho khoneha,khalase ea soda-kalakae ntse e le e 'ngoe ea lisebelisoa tsa substrate tse sebelisoang ka ho fetisisa lilaboratoring, lithupelo tsa mahlo, le lisebelisoa tsa ho roala lifilimi tse tšesaane.

Tlhahiso le Boleng ba Sefahleho

Emong le emongmotsoako oa soda-limee entsoe ka ho sebelisa likhalase tsa boleng bo holimo tse phunyeletsoang ka nepo, ho phunya, le ho bentša ka mahlakoreng a mabeli ho fihlela sebaka se sephara sa optically.

Mehato e tloaelehileng ea tlhahiso e kenyelletsa:

-

Mokhoa oa ho phaphamala:Ho hlahisa likhalase tse sephara, tse tšoanang ka theknoloji ea float tin e qhibilihisitsoeng.

-

Ho Seha le ho Bopa:Laser kapa taemane e seha ka lifomate tse chitja kapa tse khutlonnetsepa.

-

Ho benya hamonate:Ho fihlella botenya bo phahameng le boreleli ba boemo bo holimo ka lehlakoreng le le leng kapa ka bobeli.

-

Ho Hloekisa le ho Pakaletsa:Ho hloekisoa ka mokhoa oa Ultrasonic ka metsing a hloekisitsoeng, tlhahlobo e se nang likaroloana, le liphutheloana tsa kamore e hloekileng.

Ts'ebetso ena e netefatsa ho tsitsisa ho hoholo le ho qeta holimo holimo ho loketseng bakeng sa ho roala optical kapa mosebetsi oa microfabrication.

Lisebelisoa

Soda-lime substratesli sebelisoa mefuteng e pharaletseng ea lits'ebetso tsa mahlale, tsa mahlo le tsa semiconductor, ho kenyelletsa:

-

Windows le liipone tsa Optical:Lipoleiti tsa motheo bakeng sa liphahlo tsa optical le tlhahiso ea filthara.

-

Thin-Film Deposition:Li-substrates tse loketseng tsa ITO, SiO₂, TiO₂, le lifilimi tsa tšepe.

-

Bontša Theknoloji:E sebelisoa ka khalase ea mokokotlo, tšireletso ea pontšo, le lisampole tsa calibration.

-

Patlisiso ea Semiconductor:Bajari ba theko e tlase kapa li-wafers tsa liteko lits'ebetsong tsa photolithography.

-

Lisebelisoa tsa Laser & Sensor:Sesebediswa sa tshehetso se pepeneneng bakeng sa ho tsamaisana ha optical le diteko tsa probe.

-

Tšebeliso ea Thuto le Teko:E sebelisoa hangata li-lab bakeng sa liteko tsa ho koahela, ho etching le ho kopanya.

Litlhaloso Tse Tloaelehileng

| Paramethara | Tlhaloso |

|---|---|

| Lintho tse bonahalang | Khalase ea Silicate ea Soda-Lime |

| Diameter | 2", 3", 4", 6", 8" (e fumanehang ka mokhoa o ikhethileng) |

| Botenya | 0.3-1.1 limilimithara tse tloaelehileng |

| Surface Finish | E bentšitsoeng ka mahlakoreng a mabeli kapa e bentšitsoeng ka lehlakoreng le le leng |

| Bophatlalatsi | ≤15µm |

| Bokhopo ba Sefahleho (Ra) | <2 nm |

| Phetiso | ≥90% (Mofuta o bonahalang: 400–800 nm) |

| Botenya | 2.5 g/cm³ |

| Coefficient ea Katoloso ea Thermal | ~9 × 10⁻⁶ /K |

| Ho thatafala | ~ 6 Mohs |

| Refractive Index (nD) | ~ 1,52 |

LBH

Q1: Li-substrates tsa soda-lime hangata li sebelisetsoa eng?

A: Li sebelisoa e le lisebelisoa tsa motheo bakeng sa ho roala lifilimi tse tšesaane, liteko tsa optical, tlhahlobo ea photolithography, le tlhahiso ea lifensetere tsa optical ka lebaka la ho hlaka le ho bata ha tsona.

Q2: Na li-substrates tsa soda-lime li ka mamella mocheso o phahameng?

A: Li ka sebetsa ho fihlela ho 300°C. Bakeng sa ho hanyetsa mocheso o phahameng, li-borosilicate kapa li-silica tse kopantsoeng li buelloa.

Q3: Na li-substrates li loketse bakeng sa ho roala?

K: E, bokaholimo ba tsona bo boreleli ebile bo hloekile bo loketse bakeng sa ho beha mouoane oa 'mele (PVD), k'hemik'hale ea mouoane oa lik'hemik'hale (CVD), le lits'ebetso tsa sputtering.

Q4: Na ho ka khoneha ho iketsetsa?

A: Ho joalo. Boholo ba tloaelo, libopeho, botenya, le likhakanyo tse felletseng li fumaneha ho ipapisitse le litlhoko tse ikhethang tsa kopo.

Q5: Li bapisoa joang le li-substrates tsa borosilicate?

A: Khalase ea soda-lime e na le chelete e ngata ebile e bonolo ho sebetsa empa e na le khanyetso e fokolang ea mocheso le lik'hemik'hale ha e bapisoa le khalase ea borosilicate.

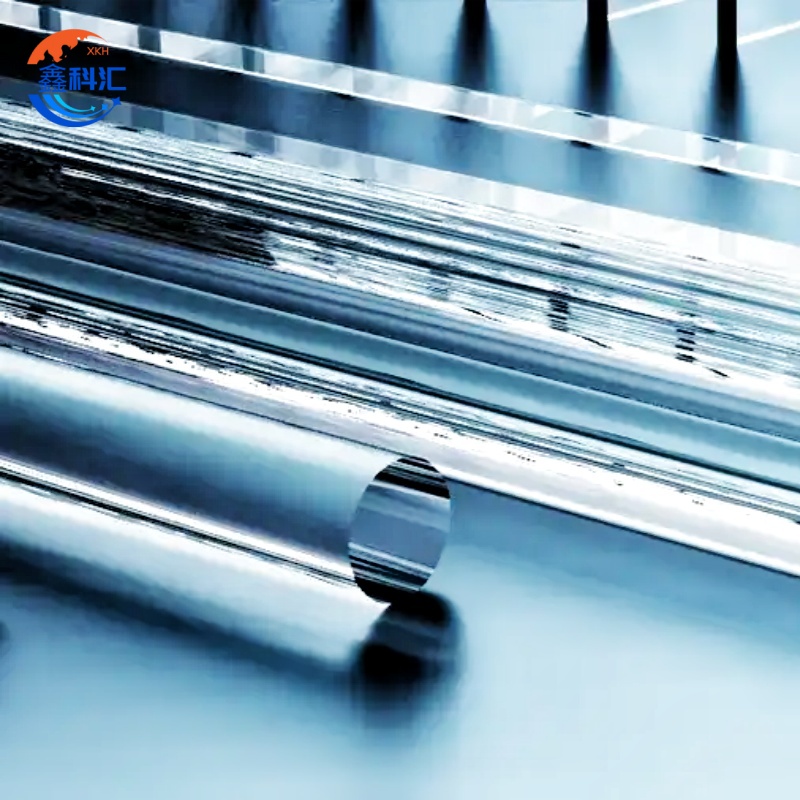

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.