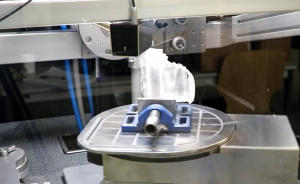

Wafer Orientation System ea Crystal Orientation Measurement

Selelekela sa Thepa

Lisebelisoa tsa Wafer orientation ke lisebelisoa tse nepahetseng tse ipapisitseng le melao-motheo ea X-ray diffraction (XRD), e sebelisoang haholo tlhahisong ea semiconductor, lisebelisoa tsa optical, ceramics le liindasteri tse ling tsa kristale.

Lisebelisoa tsena li khetholla sebopeho sa kristale lattice le ho tataisa mekhoa e nepahetseng ea ho itšeha kapa ho bentša. Lintlha tsa bohlokoa li kenyelletsa:

- Litekanyo tse nepahetseng haholo:E khona ho rarolla lifofane tsa crystallographic tse nang le liqeto tse ka tlase ho 0.001 ° ...

- Mehlala e kholo ea ho lumellana:E tšehetsa li-wafers tse fihlang ho 450 mm bophara le boima ba lik'hilograma tse 30, tse loketseng lisebelisoa tse kang silicon carbide (SiC), safire le silicon (Si).

- Moralo oa modular:Ts'ebetso e atolositsoeng e kenyelletsa tlhahlobo ea li-rocking curve, 'mapa oa sekoli sa 3D, le lisebelisoa tsa ho bokellana bakeng sa ts'ebetso ea mehlala e mengata.

Lintlha tsa bohlokoa tsa Tekheniki

| Sehlopha sa Parameter | Maemo a Tloaelehileng / Tlhophiso |

| Mohloli oa X-ray | Cu-Kα (0.4 × 1 mm sebaka se shebaneng), 30 kV e potlakisang motlakase, 0–5 mA tube e feto-fetohang |

| Angular Range | θ: -10 ° ho +50 °; 2θ: -10° ho ea ho +100° |

| Ho nepahala | Qeto ea angle e sekame: 0.001 °, ho lemoha sekoli holim'a metsi: ± 30 arcseconds (mokokotlo o sisinyehang) |

| Lebelo la ho hlahloba | Sekena sa Omega se phethela sebopeho se felletseng sa lattice ka metsotsoana e 5; Theta scanning e nka ~ motsotso o le mong |

| Sethala sa mohlala | V-groove, ho huloa ha moea, ho potoloha ha li-angle tse ngata, ho tsamaellana le li-wafers tsa 2-8-inch |

| Mesebetsi e Atolositsoeng | Tlhahlobo ea curve curve, 'mapa oa 3D, sesebelisoa sa ho bokella, ho lemoha sekoli sa mahlo (mekhoa, li-GB) |

Molao-motheo oa ho sebetsa

1. Motheo oa X-ray Diffraction

- Li-X-ray li sebelisana le li-nuclei tsa athomo le li-electrone ka har'a lesela la kristale, li hlahisa mekhoa ea ho fapana. Molao oa Bragg ( nλ = 2d sinθ ) o laola kamano pakeng tsa li-angles tsa diffraction (θ) le sebaka sa marang-rang (d).

Li-detectors li tšoara mekhoa ena, e hlahlobiloeng ho tsosolosa sebopeho sa crystallographic.

2. Omega Scanning Technology

- Kristale e potoloha e sa khaotse ho potoloha axis e tsitsitseng ha X-ray e e khantša.

- Li-Detector li bokella mats'oao a phapano ho lifofane tse ngata tsa crystallographic, tse nolofalletsang boikemisetso bo felletseng ba ho shebana le lattice ka metsotsoana e 5.

3. Rocking Curve Analysis

- Sekhutlo se tsitsitseng sa kristale se nang le li-angles tse fapaneng tsa liketsahalo tsa X-ray ho lekanya bophara ba tlhoro (FWHM), ho lekola bofokoli le khatello.

4. Taolo ea Boiketsetso

- PLC le li-touchscreen interfaces li nolofalletsa li-angles tsa ho itšeha esale pele, maikutlo a nako ea nnete, le ho hokahana le mechini ea ho itšeha bakeng sa taolo e koetsoeng.

Melemo le Likarolo

1. Ho nepahala le ho sebetsa ka katleho

- Ho nepahala ha angular ± 0.001 °, tharollo ea ho lemoha sekoli <30 arcseconds.

- Lebelo la scan la Omega le lebelo la 200 × ho feta likheo tsa setso tsa Theta.

2. Modularity le Scalability

- E ka atolosoa bakeng sa lits'ebetso tse ikhethileng (mohlala, li-wafers tsa SiC, li-blade tsa turbine).

- E hokahana le litsamaiso tsa MES bakeng sa tlhahlobo ea tlhahiso ea nako ea nnete.

3. Ho lumellana le botsitso

- E amohela lisampole tse nang le sebopeho se sa tloaelehang (mohlala, li-ingots tsa safire tse phatlohileng).

- Moralo o pholileng ka moea o fokotsa litlhoko tsa tlhokomelo.

4. Ts'ebetso e Bohlale

- Tekanyetso ea ho tobetsa ha 'ngoe le ts'ebetso ea mesebetsi e mengata.

- Ho lekanya ka boits'oaro ka likristale tsa litšupiso ho fokotsa liphoso tsa motho.

Lisebelisoa

1. Semiconductor Manufacturing

- Mokhoa oa ho qoelisa oa Wafer: E khetha Si, SiC, li-wafer tsa GaN bakeng sa ts'ebetso e ntle ea ho itšeha.

- 'Mapa o nang le liphoso: E hloaea mengoallo kapa ho kheloha holimo ho ntlafatsa tlhahiso ea chip.

2. Lisebelisoa tsa Optical

- Likristale tse se nang moeli (mohlala, LBO, BBO) bakeng sa lisebelisoa tsa laser.

- Letšoao la sefahleho sa Sapphire wafer bakeng sa likaroloana tsa LED.

3. Li-Ceramics le Composites

- E sekaseka maemo a lijo-thollo ho Si3N4 le ZrO2 bakeng sa lisebelisoa tsa mocheso o phahameng.

4. Lipatlisiso le Taolo ea Boleng

- Liunivesithi / lilab tsa nts'etsopele ea lisebelisoa tse ncha (mohlala, li-alloys tse phahameng tsa entropy).

- QC ea indasteri ho etsa bonnete ba hore batch ba lumellana.

Litšebeletso tsa XKH

XKH e fana ka ts'ehetso e felletseng ea tekheniki bakeng sa lisebelisoa tse tsamaisang liphaephe, ho kenyeletsoa ho kenya, ts'ebetso ea ts'ebetso ea paramethara, tlhahlobo e sisinyehang, le 'mapa oa bokooa ba 3D. Litharollo tse lokiselitsoeng (mohlala, theknoloji ea ingot stacking) li fanoa ho ntlafatsa katleho ea tlhahiso ea lisebelisoa tsa semiconductor le optical ka ho feta 30%. Sehlopha se inehetseng se etsa koetliso ea sebaka sa marang-rang, ha ts'ehetso e hole ea 24/7 le phetoho e potlakileng ea karolo e setseng e netefatsa ho ts'epahala ha lisebelisoa.