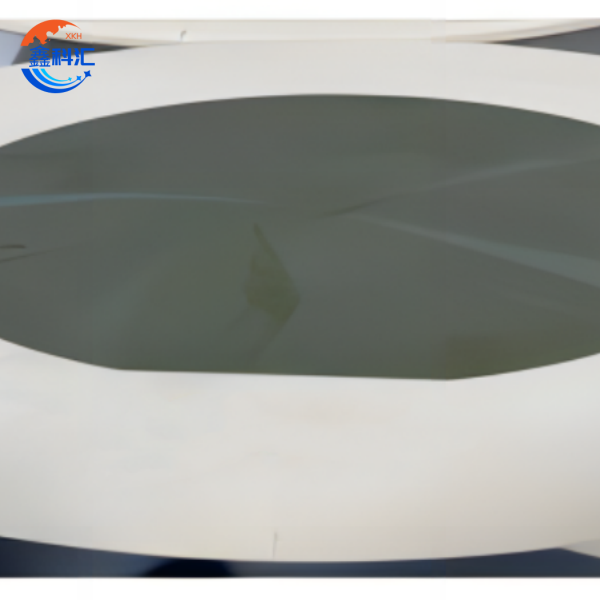

Thepa ea Wafer Thinning bakeng sa 4 Inch-12 Inch Sapphire/SiC/Si Wafers Processing

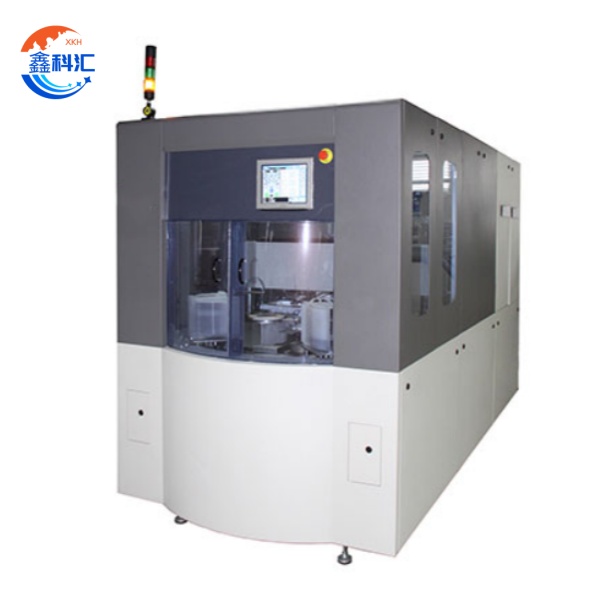

Molao-motheo oa ho Sebetsa

Ts'ebetso ea ho fokotsa li-wafer e sebetsa ka mekhahlelo e meraro:

Ho Sila ka Matla: Lebili la daemane (saese ea grit 200–500 μm) le tlosa 50-150 μm ea thepa ka 3000–5000 rpm ho fokotsa botenya ka potlako.

Ho Sila hamonate: Lebili le letle haholoanyane (boholo ba grit 1–50 μm) bo fokotsa botenya ho isa ho 20-50 μm ho <1 μm/s ho fokotsa tšenyo e ka tlas’a lefatše.

Ho hloekisoa (CMP): slurry ea lik'hemik'hale tsa lik'hemik'hale li felisa tšenyo e setseng, ho finyella Ra <0.1 nm.

Lintho Tse Lumellanang

Silicon (Si): E tloaelehileng bakeng sa li-wafers tsa CMOS, tse tšesaane ho isa ho 25 μm bakeng sa 3D stacking.

Silicon Carbide (SiC): E hloka mabili a khethehileng a daemane (80% ea daemane concentration) bakeng sa botsitso ba mocheso.

Sapphire (Al₂O₃): E tšesaane ho isa ho 50 μm bakeng sa lisebelisoa tsa UV LED.

Likarolo tsa Core System

1. Sistimi ea ho sila

Dual-Axis Grinder: E kopanya ho sila e mahoashe / e ntle sethaleng se le seng, ho fokotsa nako ea potoloho ka 40%.

Aerostatic Spindle: lebelo la lebelo la 0–6000 rpm le <0.5 μm radial runout.

2. Sistimi ea ho sebetsana le Wafer

Vacuum Chuck: > 50 N e ts'oereng matla a ± 0.1 μm ka nepo.

Robotic Arm: E tsamaisa liphaephe tse 4-12-inch ka 100 mm/s.

3. Sistimi ea taolo

Laser Interferometry: Tekolo ea botenya ba nako ea 'nete (qeto 0.01 μm).

AI-Driven Feedforward: E bolela esale pele ka ho roaloa ha mabili le ho fetola liparamente ka bo eona.

4. Ho Pholisa le ho Hloekisa

Ho hloekisa ka Ultrasonic: E tlosa likaroloana> 0.5 μm ka katleho ea 99.9%.

Metsi a Deionized: A pholisa sephaphatha ho fihla ho <5°C ka holim'a tikoloho.

Melemo ea Konokono

1. Ultra-High Precision: TTV (Total Thickness Variation) <0.5 μm, WTW (Kahare-Wafer Thickness Variation) <1 μm.

2. Multi-Process Integration: E kopanya ho sila, CMP, le plasma etching mochine o le mong.

3. Tšebelisano 'moho:

Silicon: Phokotso ea botenya ho tloha ho 775 μm ho isa ho 25 μm.

SiC: E fihlella <2 μm TTV bakeng sa lits'ebetso tsa RF.

Li-wafers tsa Doped: Li-wafers tsa phosphorus-doped InP tse nang le <5% resistivity drift.

4. Smart Automation: Ho kopanya MES ho fokotsa liphoso tsa batho ka 70%.

5. Tšebeliso ea Matla a Matla: 30% ea tšebeliso e tlase ea matla ka braking e nchafatsang.

Lisebelisoa tsa Bohlokoa

1. Packaging e tsoetseng pele

• 3D ICs: Wafer thinning e thusa ho bokellana ka ho otloloha ha logic/memory chips (mohlala, HBM stacks), ho fihlella 10× high bandwidth le 50% e fokotsehileng tšebeliso ea matla ha e bapisoa le tharollo ea 2.5D. Thepa e ts'ehetsa bonding ba hybrid bonding le TSV (Through-Silicon Via) kopanyo, e bohlokoa bakeng sa li-processor tsa AI/ML tse hlokang <10 μm interconnect pitch. Mohlala, li-wafers tse 12-inch tse tšesaane ho isa ho 25 μm li lumella ho bokella likarolo tse 8+ ha li ntse li boloka <1.5% warpage, e bohlokoa bakeng sa litsamaiso tsa likoloi tsa LiDAR.

• Sephutheloana sa Fan-Out: Ka ho fokotsa botenya ba wafer ho 30 μm, bolelele ba khokahanyo bo khutsufatsoa ka 50%, ho fokotsa tieho ea matšoao (<0.2 ps/mm) le ho nolofalletsa 0.4 mm li-chiplets tse tšesaane haholo bakeng sa li-SoC tse tsamaeang. Ts'ebetso e phahamisa li-algorithms tsa ho sila tse lefelloang ke khatello ea maikutlo ho thibela warpage (> 50 μm TTV control), ho netefatsa ts'epahalo lits'ebetsong tse phahameng tsa RF.

2. Motlakase oa elektroniki

• IGBT Modules: Ho tšesaane ho 50 μm ho fokotsa ho hanyetsa mocheso ho <0.5 ° C / W, ho nolofalletsa 1200V SiC MOSFETs ho sebetsa mocheso oa 200 ° C. Lisebelisoa tsa rona li sebelisa ho sila ka mekhahlelo e mengata(mahoashe: 46 μm grit → e ntle: 4 μm grit) ho felisa tšenyo e ka tlas'a lefatše, ho fihlela> 10,000 cycles ea ho tšepahala ha libaesekele tse futhumetseng. Sena se bohlokoa bakeng sa li-inverters tsa EV, moo li-wafers tsa SiC tse 10 μm tse teteaneng li ntlafatsang lebelo la ho fetoha ka 30%.

• Lisebelisoa tsa Matla a GaN-on-SiC: Wafer e tšesaane ho isa ho 80 μm e ntlafatsa ho tsamaea ha elektronike (μ > 2000 cm²/V·s) bakeng sa 650V GaN HEMTs, ho fokotsa tahlehelo ea conduction ka 18%. Ts'ebetso ena e sebelisa "laser-assisted dicing" ho thibela ho phatloha nakong ea ho ota, ho fihlela <5 μm edge chipping bakeng sa liamplifi tsa matla tsa RF.

3. Optoelectronics

• Li-LED tsa GaN-on-SiC: Li-substrates tsa 50 μm tsa safire li ntlafatsa bokhoni ba ho ntša leseli (LEE) ho ea ho 85% (vs. 65% bakeng sa li-wafers tsa 150 μm) ka ho fokotsa ho tšoasoa ha photon. Taolo ea rona ea TTV e tlase haholo (<0.3 μm) e netefatsa tlhahiso e ts'oanang ea LED ho pholletsa le li-wafers tse 12-inch, e leng ea bohlokoa bakeng sa lipontšo tsa Micro-LED tse hlokang <100nm wavelength ho ts'oana.

• Silicon Photonics: Li-wafers tsa silicon tse teteaneng tsa 25μm li nolofalletsa 3 dB / cm tahlehelo e fokolang ea ho phatlalatsoa ho li-waveguides, tse hlokahalang bakeng sa 1.6 Tbps transceivers optical. Ts'ebetso e kopanya CMP boreleli ho fokotsa ho hlaba holimo ho Ra <0.1 nm, ho ntlafatsa katleho ea ho kopanya ka 40%.

4. Li-Sensors tsa MEMS

• Accelerometers: 25 μm silicon wafers finyella SNR > 85 dB (vs. 75 dB bakeng sa 50 μm wafers) ka ho eketsa bopaki-boima ba displacement kutlo. Sistimi ea rona ea li-axis tse peli e lefella likhatello tsa khatello ea maikutlo, e netefatsa hore <0.5% ea kutlo e hoholeha ho feta -40°C ho isa ho 125°C. Lisebelisoa li kenyelletsa ho lemoha ha likoloi li soahlamane le ho latedisa motsamao wa AR/VR.

• Li-Sensors tsa Khatello: Ho tšesaane ho isa ho 40 μm ho nolofaletsa 0–300 methapo ea ho metha ka <0.1% FS hysteresis. U sebelisa li-bonding tsa nakoana (lijari tsa khalase), ts'ebetso e qoba ho robeha ha sephaephe nakong ea etching e ka morao, ho fihlela <1 μm ho mamella khatello e feteletseng bakeng sa li-sensor tsa IoT tsa indasteri.

• Tekheniki Synergy: Thepa ea rona e tšesaane e kopanya ho sila ka mochini, CMP, le plasma etching ho rarolla mathata a fapaneng a thepa (Si, SiC, Sapphire). Mohlala, GaN-on-SiC e hloka ho sila ka lebasetere (mabili a daemane + plasma) ho leka-lekanya ho thatafala le ho atolosoa ha mocheso, ha li-sensor tsa MEMS li batla bokhopo ba bokaholimo ba 5 nm ka ho belisoa ha CMP.

• Phello ea Indasteri: Ka ho nolofalletsa li-wafers tse tšesaane, tse sebetsang hantle haholo, theknoloji ena e khanna mekhoa e mecha ho li-chips tsa AI, 5G mmWave modules, le lisebelisoa tsa motlakase tse feto-fetohang, tse nang le mamello ea TTV <0.1 μm bakeng sa lipontšo tse phuthoang le <0.5 μm bakeng sa lisensara tsa LiDAR tsa likoloi.

Litšebeletso tsa XKH

1. Customized Solutions

Litlhophiso tse Scalable: meralo ea kamore ea 4-12-inch e kenyang / ho laolla.

Tšehetso ea Doping: Litlolo tse tloaelehileng tsa likristale tsa Er/Yb-doped le li-wafers tsa InP/GaAs.

2. Tšehetso ea ho qetela

Nts'etsopele ea Ts'ebetso: Teko ea mahala e sebetsa ka optimization.

Koetliso ea Lefatše: Lithupelo tsa tekheniki selemo le selemo mabapi le tlhokomelo le ho rarolla mathata.

3. Multi-Material Processing

SiC: Wafer e tšesaane ho isa ho 100 μm ka Ra <0.1 nm.

Sapphire: botenya ba 50μm bakeng sa lifensetere tsa laser tsa UV (transmittance>92%@200 nm).

4. Litšebeletso tsa Keketso ea Boleng

Phepelo e ka jeoang: Mabili a daemane (li-wafers tse 2000+ / bophelo) le li-slurries tsa CMP.

Qetello

Sesebediswa sena sa wafer thinning se fana ka ts'ebetso e etelletseng pele indastering, ho sebetsa ka mefuta e mengata ea lintho tse ngata, le automation e bohlale, e etsa hore e be ea bohlokoa bakeng sa ho kopanya 3D le lisebelisoa tsa elektroniki tsa motlakase. Lits'ebeletso tse felletseng tsa XKH - ho tloha ho tlhophiso ho isa ho ts'ebetso ea morao-rao - etsa bonnete ba hore bareki ba fihlella katleho ea litšenyehelo le bokhabane ba ts'ebetso molemong oa tlhahiso ea semiconductor.