Diamond-Copper Composite Thermal Management Materials

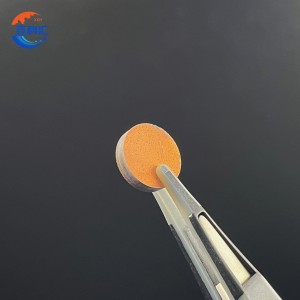

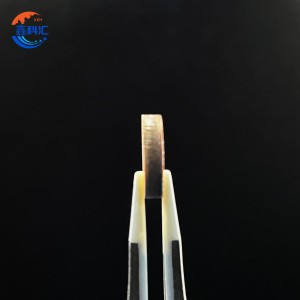

Setšoantšo se qaqileng

Kenyelletso ea Sehlahisoa

TheMotsoako oa Diamond-Copper (Cu-Diamond)ke anultra-high-performance thermal management materiale kopanyang motlakase o motle ka ho fetisisa lefatšeng -taemane- ka thepa e phahameng ea motlakase le ea mochini eakoporo.

E etselitsoe bakeng sa lisebelisoa tsa elektronike le lisebelisoa tsa motlakase, motsoako ona o finyella tekanyo e ikhethang eaho feteletseng ha mocheso oa mocheso, katoloso ea mocheso e laolehang, lebotsitso ba mochini, e nolofalletsang ts'ebetso e ka tšeptjoang esita le tlas'a maemo a boima ka ho fetisisa a mocheso.

Ho fapana le likaroloana tse tloaelehileng tsa koporo, tungsten, kapa molybdenum, metsoako ea Diamond-Copper e fana ka thepa.ho fihlela makhetlo a mabeli a mocheso oa mochesoha a ntse a fokotsa boima ba 'mele haholo, ho ba etsa khetho e ratoang bakeng saliphutheloana tsa semiconductor, litsamaiso tsa laser, lisebelisoa tsa elektroniki tsa sefofane, le li-module tsa LED tse matla haholo.

Molao-motheo oa Lintho

Bohareng ba mashano a kopantsoenglikaroloana tsa taemaneka tsela e ts'oanang e kentsoeng ka hare ho amatrix a koporo.

Karolo e 'ngoe le e' ngoe ea daemane e sebetsa e le teba ea mocheso o monyenyane, o jala mocheso ka potlako, ha matrix ea koporo e tiisa ho tsamaisoa ha motlakase le botšepehi ba sebopeho.

Ka mekhoa e tsoetseng pele ea tlhahiso - ho kenyelletsaho kenella ka vacuum, ho roala ka lik'hemik'hale, lespark plasma sintering (SPS)- ho thehoa bond e matla le e tsitsitseng ea sebopeho, e tiisang ho tšepahala ha nako e telele tlas'a libaesekele tse sa khaotseng tsa mocheso.

Lintlha-khōlō Tsa Theknoloji

| | |

|---|---|

| | |

| | |

| | |

| | |

| | |

Lisebelisoa

-

Li-Module tsa Semiconductor tse Matla a Phahameng(GBT, MOSFET, RF & liphutheloana tsa microwave)

-

Lisebelisoa tsa Laser Diode le Optoelectronic Devices

-

Aerospace le Ts'ireletso ea ho Pholisa Sistimi

-

Lisebelisoa tsa Mocheso oa LED tse Phahameng ka ho Fetisisa

-

IC le CPU Heat Sinks bakeng sa Advanced Computing

-

Li-amplifiers le lisebelisoa tsa puisano tsa Optical

Ke Hobane'ng ha U Khetha Motsoako oa Diamond-Copper?

Hobanelitaba tsa mocheso.

Nakong ea miniaturization le matla a phahameng a matla, ho laola mocheso ka katleho ho hlalosa bophelo le ts'ebetso ea sesebelisoa se seng le se seng.

Motsoako oa Cu-Diamond o netefatsa:

-

Nako e telele ea bophelo ba sesebelisoa

-

Botsitso bo matlafalitsoeng ba ts'ebetso

-

Matla a matla a ntlafetseng

-

Mokhathala o fokotsehileng oa mocheso

FAQ ea Likhalase tsa Quartz

Q1: Na li-composite tsa Cu-Diamond li ka etsoa bakeng sa lisebelisoa tse khethehileng tsa chip?

Ee. Karolo ea bophahamo ba daemane le CTE e ka hlophisoa hantle hore e bapise lisebelisoa tse thehiloeng ho Si, GaN kapa SiC.

Q2: Na metallization ea hlokahala pele ho soldering?

Ee. Surface metallization (Ni/Au, Ti/Ni/Au) e khothaletsoa ho netefatsa tlamahano e ntle haholo le ho hanyetsa mocheso o fokolang.

Q3: E sebetsa joang tlas'a maemo a mocheso a phahameng-frequency kapa pulsed?

Phatlalatso e phahameng ea mocheso oa Diamond e tiisa ho lekana ha mocheso ka potlako, ho etsa hore e be e loketseng bakeng sa likarolo tse phahameng tsa maqhubu le tse nang le pulse.

Q4: Mocheso o phahameng ka ho fetisisa oa ho sebetsa ke ofe?

The composite e ntse e tsitsitse ho fihlela600°Cmaemong a inert kapa a vacuum, ho ipapisitse le sebopeho sa ho roala le ho kopanya.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.