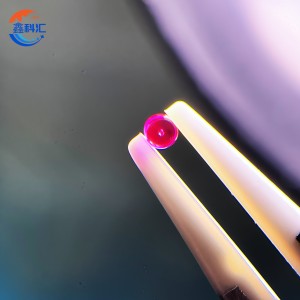

Ka-Hole Ruby Bearing

Setšoantšo se qaqileng

Tlhaloso ea Sehlahisoa

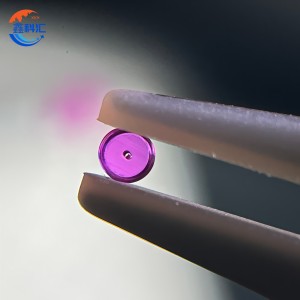

Li-ruby tse nang le lesoba ke likarolo tse entsoeng ka mokhoa o nepahetseng tse entsoeng ka ruby ea maiketsetso ea kristale e le 'ngoe (Al₂O₃ e entsoeng ka Cr₂O₃). Li-bearings tsena li entsoe ka sebopeho se bohareng sa lesoba se lumellang li-shafts, likhoele kapa likhoele tsa optical hore li fete hantle ha li ntse li fokotsa likhohlano le ho roala. Ka lebaka la boima bo feteletseng ba ruby (Mohs 9), botsitso bo ikhethang ba lik'hemik'hale, le pheletso e ntle ea bokaholimo, li-bearings tsena li sebelisoa haholo lisebelisoa tse nepahetseng, lisebelisoa tsa metering, likopano tsa fiber optic, le lisebelisoa tse nyane tsa mochini moo botsitso le nako e telele ea bophelo li leng bohlokoa.

Thepa le Sebopeho

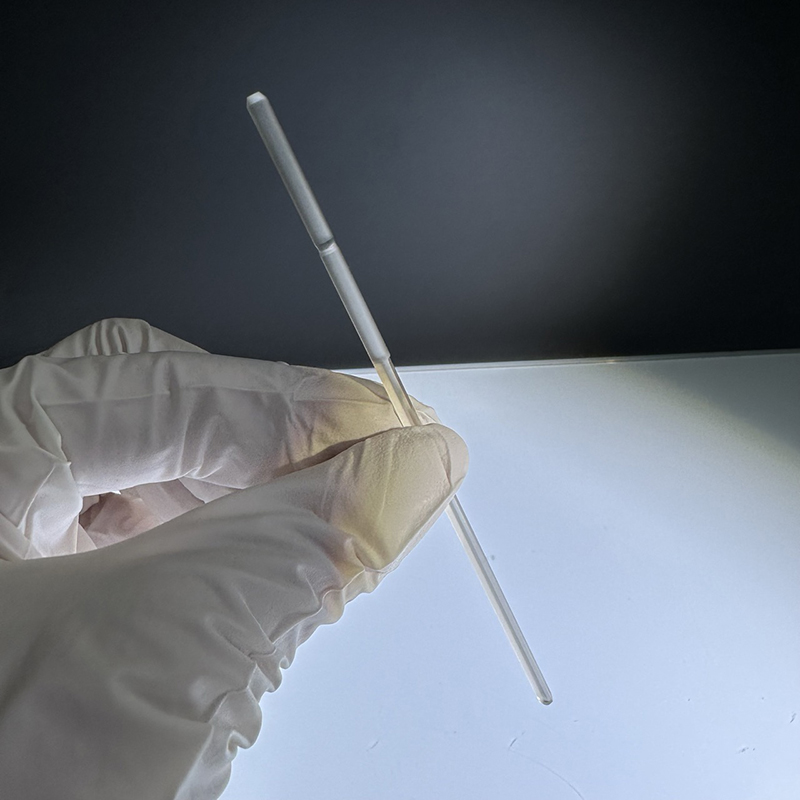

'Mele o jereng o entsoe ka kristale ea maiketsetso ea corundum, e hōlileng tlas'a maemo a laoloang ho etsa bonnete ba hore ho thata ho tšoana le ho hloeka. Chromium doping e fa thepa 'mala oa eona o mofubelu' me e eketsa ho hlaka le ho hanyetsa kutu. The through-hole e entsoe ka nepo le ho belisoa ho fihlela boemo bo nepahetseng ba micron-dimensional le boreleli, ho netefatsa coaxiality e ntle haholo le khohlano e tlase ho motsamao oa rotary kapa oscillating.

Li-Parameters tse Tloaelehileng

| Paramethara | Boleng |

|---|---|

| Lintho tse bonahalang | Synthetic Ruby (Al₂O₃ + trace Cr₂O₃) |

| Ho thatafala | 9 ka tekanyo ea Mohs |

| Botenya | 3.98g/cm³ |

| Mocheso oa Mosebetsi | -60°C ho isa ho 500°C |

| Bore Diameter | 0.05–5.0 limilimithara (ka tloaelo e teng) |

| Kantle Diameter | 0.5-10 limilimithara |

| Mamello ea Roundness | ≤ 0.0025 limilimithara |

| Surface Finish | Ra ≤ 0.02 μm |

Lintlha tsa Setsebi

Boima bo Feteletseng le Botsitso - kristale ea ruby e hanela deformation, abrasion, le tlhaselo ea lik'hemik'hale esita le libakeng tse matla tsa ts'ebetso.

Precision Through-Hole Design - Bore e 'ngoe le e' ngoe e phethetsoe ka polishing ea boemo bo holimo bakeng sa motsamao o boreleli le likhohlano tse nyane.

Corrosion and Wear Resistance - Li-ruby bearings li boloka ts'ebetso ea mongobo, li-solvents le li-acids ntle le ho senyeha.

Ho Nepaha ho Haholo ha Geometric - Ho etsoa ka mokhoa o thata oa ho etsa thepa ho netefatsa hore ho na le tlhophiso e phethahetseng ea coaxial le ho pota-pota bakeng sa ho potoloha ha bonolo.

Ho ts'epahala ha nako e telele - E sebetsa lilemo tse ngata ntle le ho tlotsa kapa ho hoholeha, e loketse lits'ebetso tse tsoelang pele kapa tse pheta-phetoang.

Lisebelisoa

Marang-rang a ruby ka lesoba a sebelisoa hangata ho:

-

Lisebelisoa tsa ho Metha Ka nepo:Li-micrometer, li-gauge, le lisebelisoa tsa metrology tse hlokang ho nepahala ho tsitsitseng ho tsitsitseng.

-

Sistimi ea Optical le Laser:E sebetsa e le lintlha tse tataisang le ho beha maemo bakeng sa likhoele tsa optical, lilense le lisebelisoa tsa alignment ea laser.

-

Liwache le Mechini e Menyane:E fana ka li-pivot tse sa sebetseng bakeng sa li-shaft tse nyenyane tse bilikang le li-axle.

-

Lisebelisoa tsa Bongaka:E sebelisoa lipompong tsa mokelikeli, lits'ebetso tsa tlhahlobo, le likarolo tsa taolo ea phallo moo ho nepahala ha mochini ho leng bohlokoa.

-

Thepa ea Aerospace le Navigation Navigation:Ho netefatsa botsitso le ho nepahala ha mekhoa e sebetsang hantle le e thibelang ho sisinyeha.

LBH

Q1: Ke eng e etsang hore libere tsa ruby tse ka har'a lesoba li loketse lisebelisoa tse nepahetseng?

K: Ho thatafala ha tsona, ho pota-pota, le boreleli bo boreleli bo fokotsa ho thothomela le khohlano, e leng ntho ea bohlokoa bakeng sa motsamao o nepahetseng le o tsitsitseng lisebelisoa tsa ho metha tse nepahetseng.

Q2: Na li ka sebelisoa maemong a vacuum kapa a hloekileng?

A: Ho joalo. Li-ruby bearings ha li na lisebelisoa tse senyehang ka ho feletseng 'me li sebetsa ka mokhoa o phethahetseng ntle le lubrication, e leng se etsang hore e be tse loketseng bakeng sa libaka tsa vacuum kapa semiconductor.

Q3: Na ho na le mefokolo holim'a thepa ea shaft kapa qetellong ea bokaholimo?

K: Bakeng sa ts'ebetso e nepahetseng, ho khothaletsoa lithupa tse entsoeng ka tšepe e sa hloekang e bentšitsoeng, tungsten carbide kapa safire ho fokotsa likhohlano le ho khathala.

Q4: A na nka kopa saese e sa tloaelehang ea bore kapa geometry ea kantle?

A: Ho joalo. Re ts'ehetsa li-bearings tsa ruby tse hlophisitsoeng ka botlalo ho latela lits'oants'o, ho kenyeletsoa bore ea asymmetric, li-countersink le meralo ea flange.

Q5: Ruby e bapisoa joang le safire bakeng sa ho kenya lits'ebetso?

A: Ka bobeli li na le libopeho tse tšoanang tsa kristale le ho thatafala, empa ruby's chromium doping e ntlafatsa ponahalo le mokhoa oa ho apara, e leng se etsang hore e be khetho e ntle hanyenyane bakeng sa ho shebella ka mochine le ho hlahloba mahlo.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.