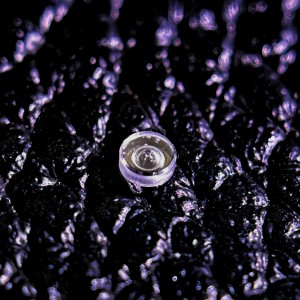

Ka-Hole Hole Transparent Sapphire Components

Setšoantšo se qaqileng

Kakaretso

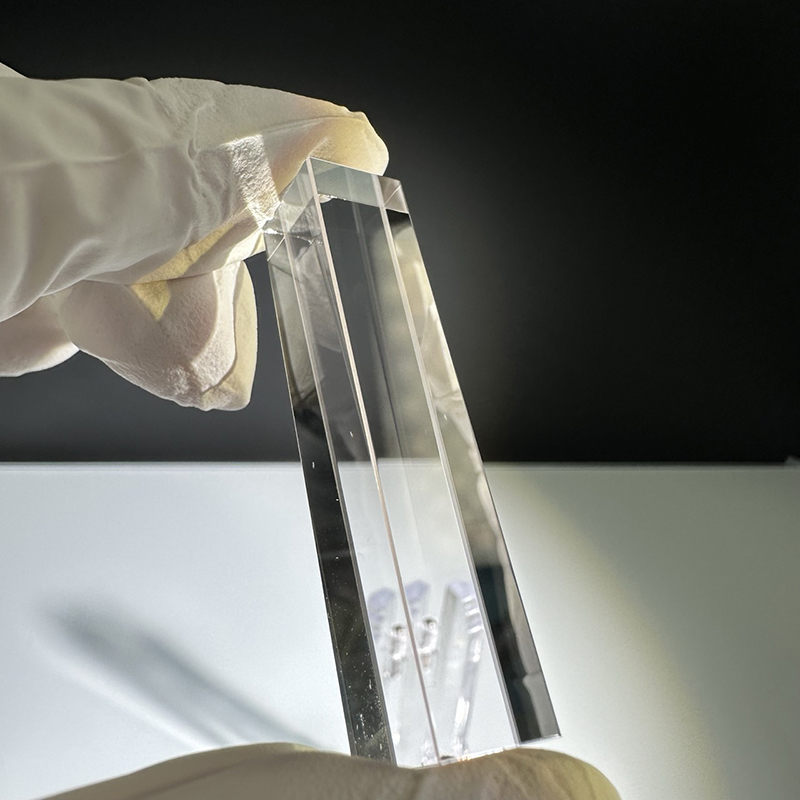

Likarolo tsa safire tse pepeneneng ka lesoba ke likarolo tse entsoeng ka nepo tse entsoeng ho tsoa ho single-crystal aluminium oxide (Al₂O₃), thepa e tsebahalang ka ho kopanya ha eona pepeneneng, boima bo phahameng le ho se sebetse ha lik'hemik'hale. Likarolo tsena li na le masoba a phuntsoeng ka nepo a lumellang ho kopanngoa ha mochini, ho tsamaisana le optical, kapa likanale tse laoloang ha li ntse li boloka ts'ebetso e ntle haholo ea optical le sebopeho. Motsoako oa bona o ikhethang oa mesebetsi ea optical le ea mochini e ba etsa ba bohlokoa haholo indastering ea semiconductor, aerospace, photonics le liindasteri tsa lisebelisoa.

Litšobotsi tsa Lintho

Lintho tse ikhethang tsa Sapphire li bakoa ke sebopeho sa kristale e le 'ngoe le botsitso ba lik'hemik'hale. Ka boima ba 9 sekaleng sa Mohs, safire e fana ka khanyetso e ikhethang ea abrasion le botsitso ba sebopeho le tlas'a meroalo e phahameng. E na le ponahalo e hlakileng ho pholletsa le mefuta e mengata ea mahlaseli-ho tloha ho mahlaseli a kotsi a tebileng (UV) ho ea ho khanya e bonahalang ho ea bohareng ba infrared (IR) - 'me e boloka ho hlaka tlas'a khatello e phahameng ea mocheso. Sebaka se qhibilihang sa Sapphire se feta 2000°C, 'me se bontša khanyetso e ntle ho li-acids, alkalis, le plasma.

Melemo ea Konokono

-

Ponaletso e Phahameng:Phetiso e tloha ho 190 nm ho isa ho 5000 nm, e netefatsa tahlehelo e nyane ea optical lits'ebetsong tsa UV-IR.

-

Matla a Hlollang a Mechini:Matla a phahameng a khatello le a flexural bakeng sa tšebeliso ea khatello le likamore tsa vacuum.

-

Thermal Robustness:E boloka ts'ebetso ea sebopeho le ea optical maemong a mocheso a feteletseng.

-

Ho hanyetsa Lik'hemik'hale le Plasma:Ha e sebetsane le boholo ba li-reagents tsa lik'hemik'hale 'me e tsitsitse ho plasma kapa moeeng o senyang.

-

Precision Engineering:Likoti li ka chekoa, tsa koaheloa, kapa tsa koaheloa ka ho mamellana ka har'a ± 5 µm.

-

Ho Tšepahala ha Nako e Telele:Ha ho na ho senyeha ha thepa ea optical kapa ea mochine ka lebaka la tšebeliso ea nako e telele.

Lisebelisoa

-

Tlhahiso ea Semiconductor:

E sebelisoa e le lifensetere tsa ho hlahloba, li-nozzles tsa khase, kapa likarolo tsa ho itšehla thajana ho CVD, PECVD, le lisebelisoa tsa etching, moo botsitso ba mocheso le bohloeki li leng bohlokoa. -

Lisebelisoa tsa Optical le Photonic:

E sebetsa e le lisebelisoa tse optical mounts, lifensetere tsa sensor, kapa likhokahano tse tataisang leseli tse hlokang masoba bakeng sa ho tsamaisana, ho kopanya likhoele, kapa tsela ea laser beam passage. -

Sepakapaka le Tšireletso:

E kenyelelitsoe ho li-sensor tsa optical tse nepahetseng haholo, lisebelisoa tsa litšoantšo, le likoahelo tse sireletsang tse sebetsang tlas'a ho sisinyeha, tšusumetso, kapa khatello ea mocheso. -

Lisebelisoa tsa Tlhahlobo le tsa Bongaka:

E sebelisoa liseleng tse phallang, likamoreng tsa sampuli, le lits'ebetso tsa tlhahlobo bakeng sa tlhahlobo ea spectroscopy kapa microfluidic. -

Lisebelisoa tsa Indasteri le Lipatlisiso:

E sebetsa e le li-spacers tsa mochini tse sa sebetseng, li-jigs tsa ho tsamaisana, le litšoantšiso tse nepahetseng ho litlhophiso tsa liteko le tsa metrology.

Litlhaloso Tse Tloaelehileng

| Thepa | Tlhaloso |

|---|---|

| Lintho tse bonahalang | Single-Crystal Sapphire (Al₂O₃ ≥ 99.99%) |

| Boitloaelo | C-axis, A-axis, kapa R-axis (ho ikhethela) |

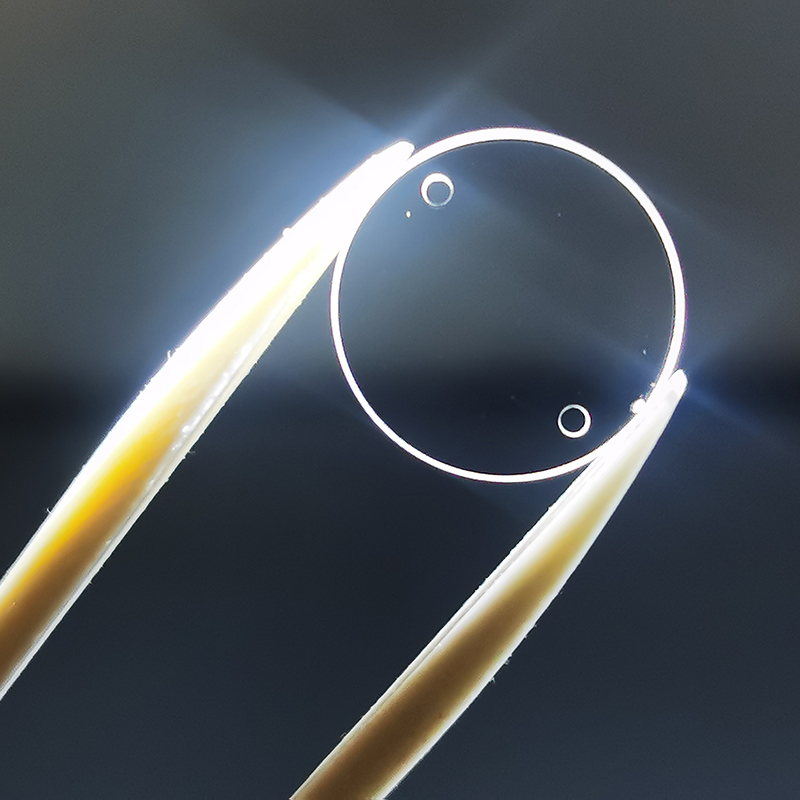

| Kantle Diameter | 2 limilimithara - 100 limilimithara |

| Botenya | 0.3 limilimithara - 20 limilimithara |

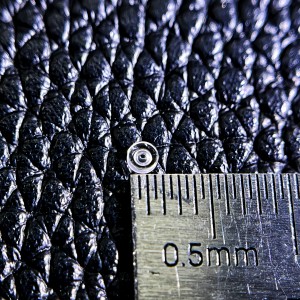

| Hole Diameter | 0.2 limilimithara - 10 limilimithara (ka tloaelo) |

| Phetiso ea Optical | >85% (400–2000 nm) |

| Bophahamo bo Sephara | λ/10 kapa ho feta |

| Ho bapisa | ≤3 arcmin |

| Scratch-Chepa | 10-5, 20-10 boikhethelo |

| Mocheso Range | −200°C ho ea ho +2000°C |

| Likhetho tsa ho roala | AR, HR, DLC, kapa liaparo tsa tloaelo tse tšesaane tsa filimi |

LBH

Q1: Ke eng e etsang hore likarolo tsa safire ka lesoba li tšoanelehe bakeng sa litsamaiso tsa semiconductor?

A1: Sapphire e kopanya ho kenya motlakase ka bohloeki bo phahameng, ho hanyetsa mocheso, le botsitso ba lik'hemik'hale, e leng se etsang hore e be se loketseng bakeng sa likamore tsa plasma, li-ports tsa optical monitoring, le likarolo tsa ho tsamaisana.

Q2: Na likoti li ka chekoa ka sekhutlo kapa ka geometry ea conical?

A2: Ho joalo. Sapphire e ka etsoa ka laser-drilled kapa ultrasonically machined ka li-angles tse sa tšoaneng ho finyella optical axis alignment kapa mesebetsi ea ho laola metsi.

Q3: Na litlolo kapa litlhare tse holim'a metsi li teng?

A3: Liaparo tse ngata tse kang li-anti-reflective, infrared-enhanced, kapa carbon-like diamond (DLC) li ka sebelisoa ho ntlafatsa ts'ebetso tlas'a maemo a itseng a spectral kapa mechine.

Q4: Ke mamello efe e ka finyelloang?

A4: Mamello ea boholo ka hare ho ± 5 µm le mamello ea angular tlas'a 3 arcmin e ka finyelloa ka CNC e nepahetseng le taolo ea ho bentsa.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.