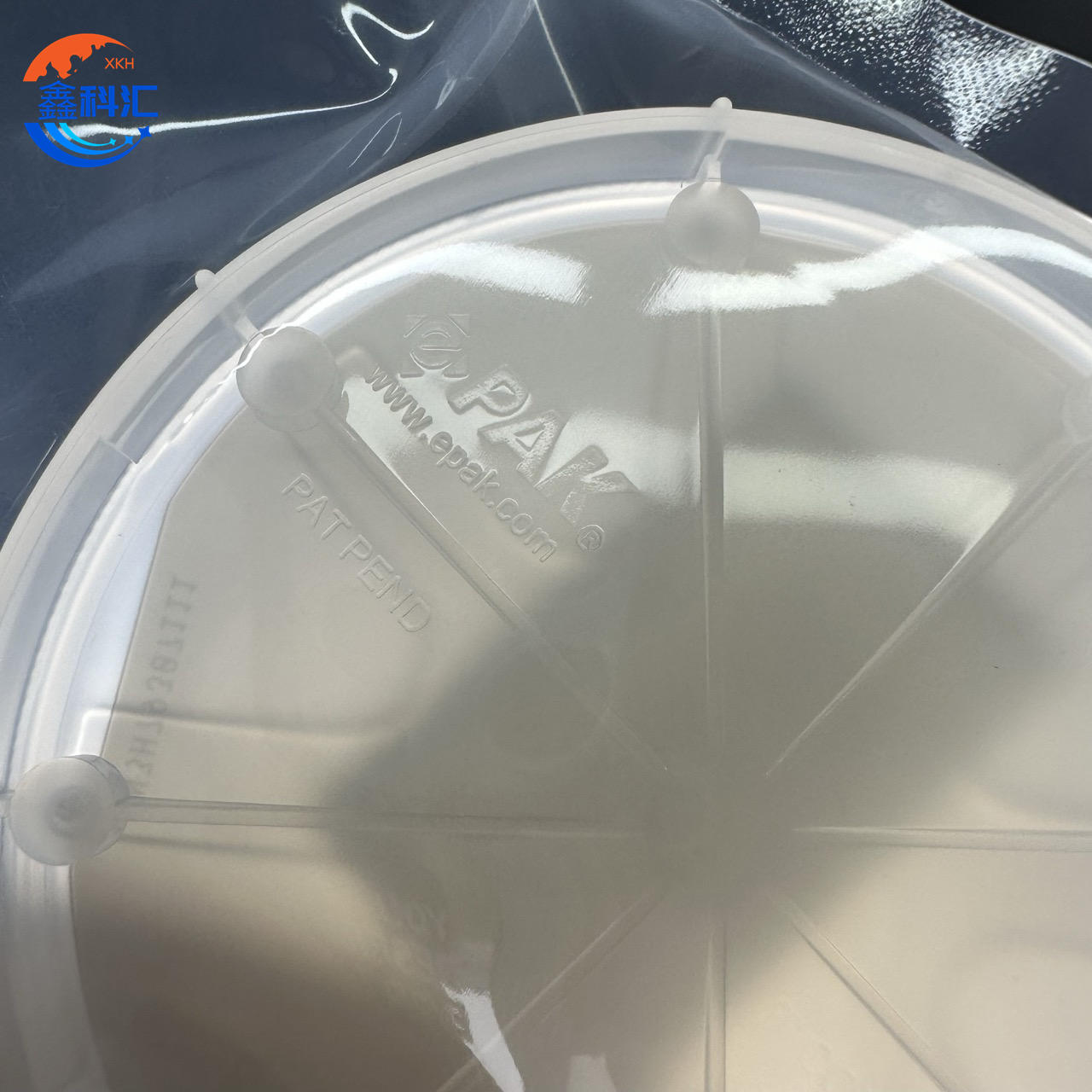

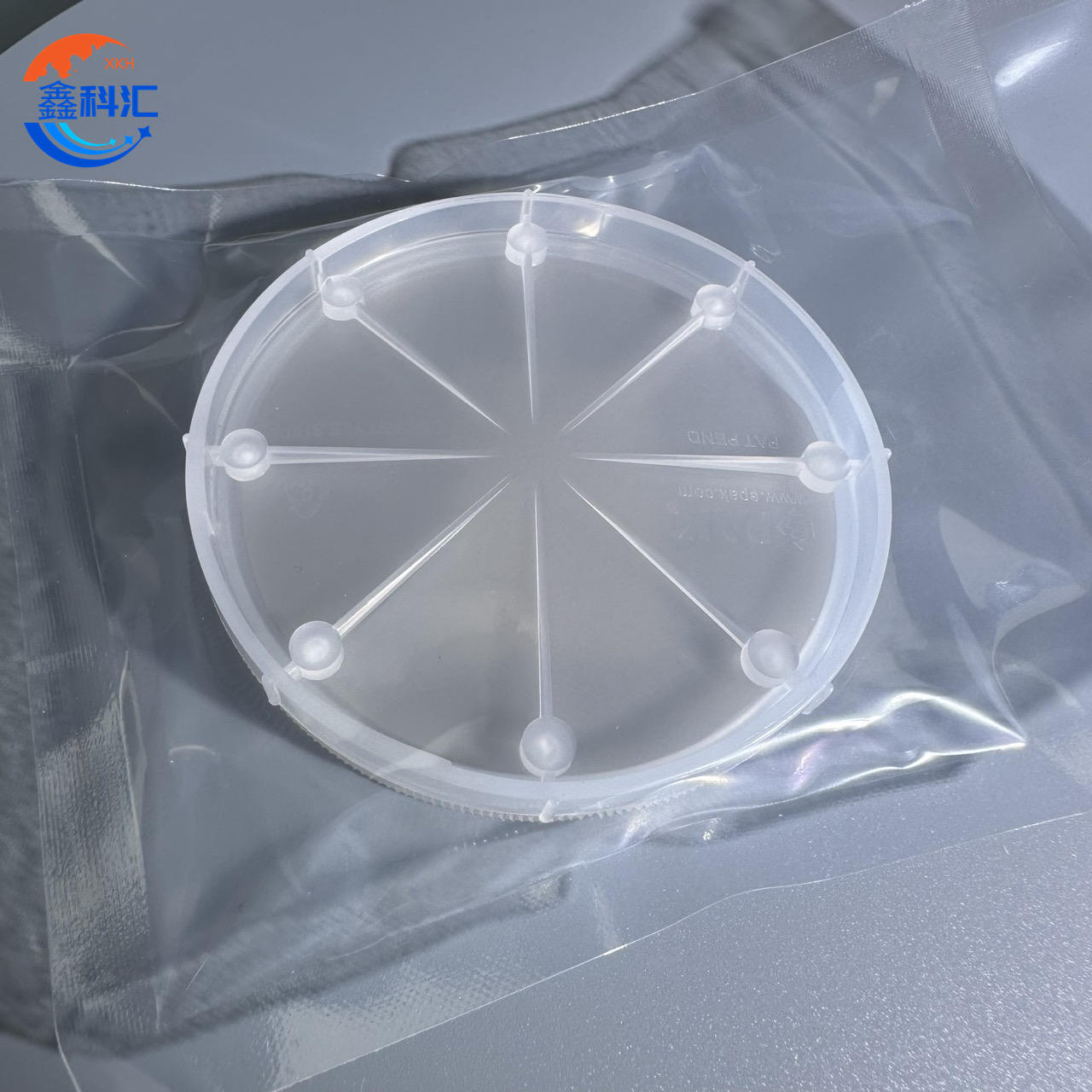

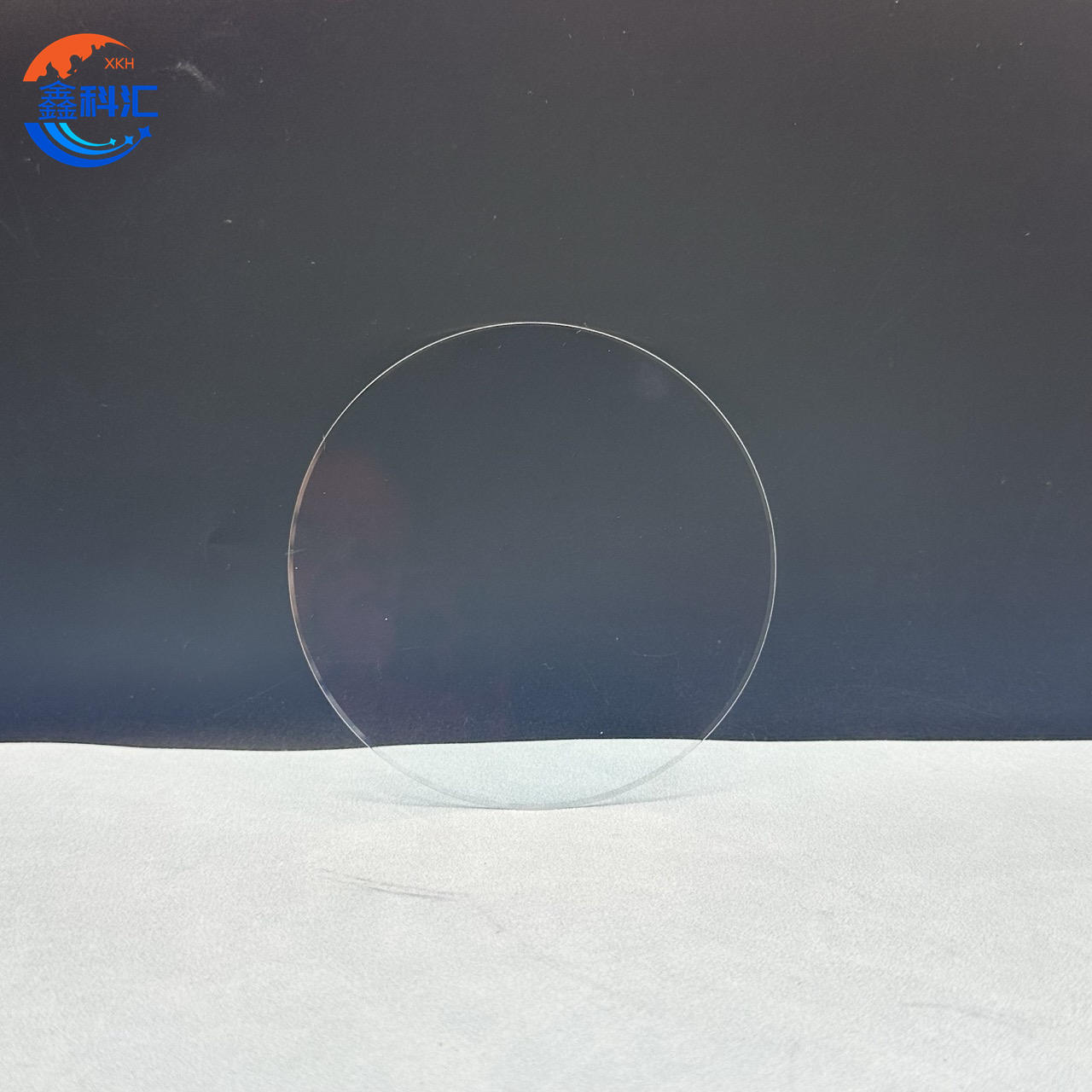

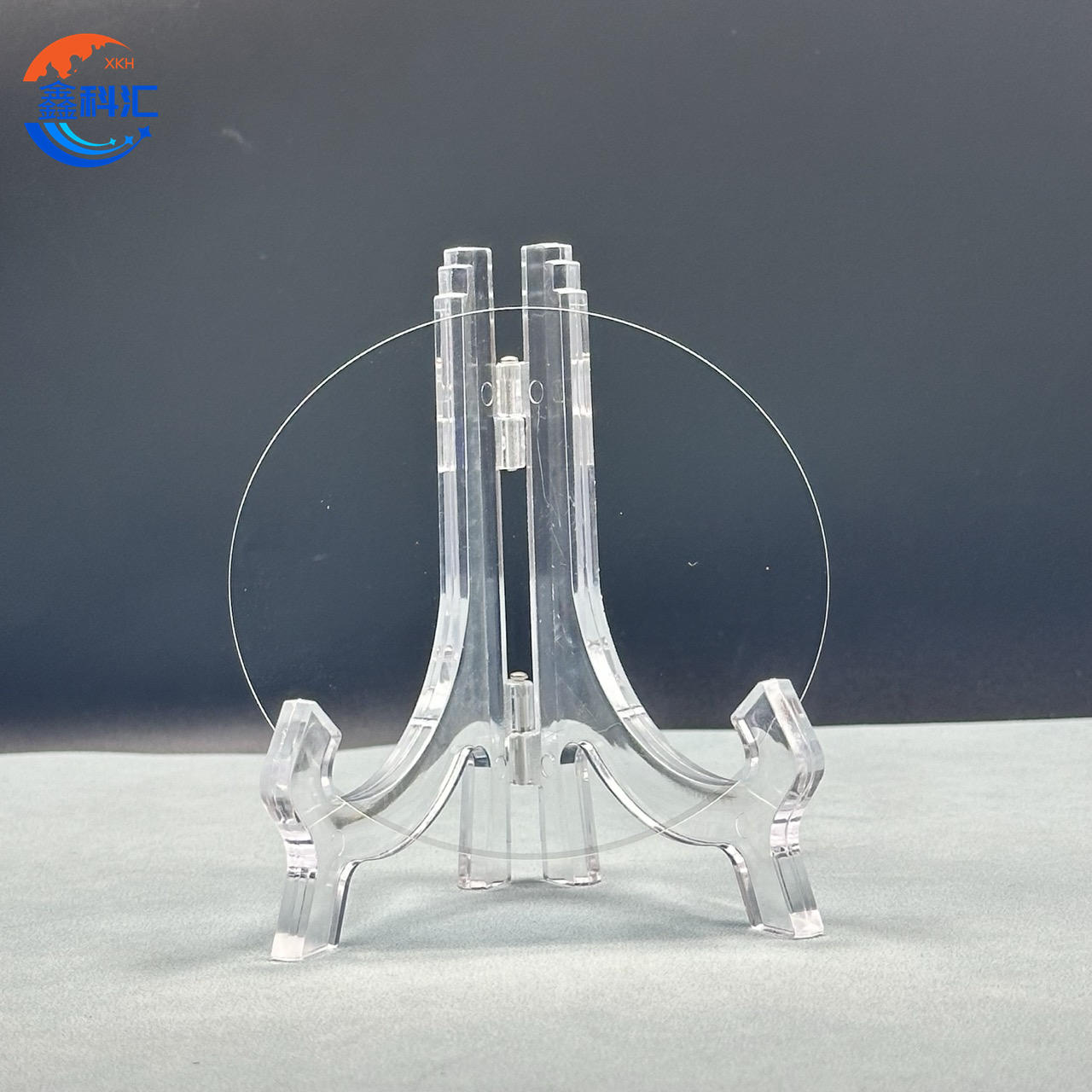

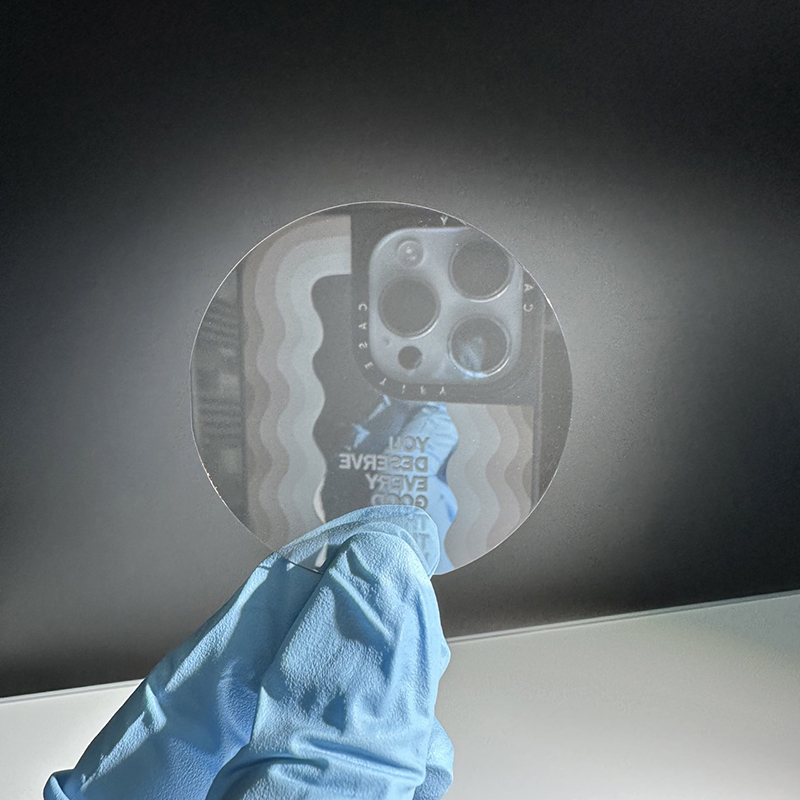

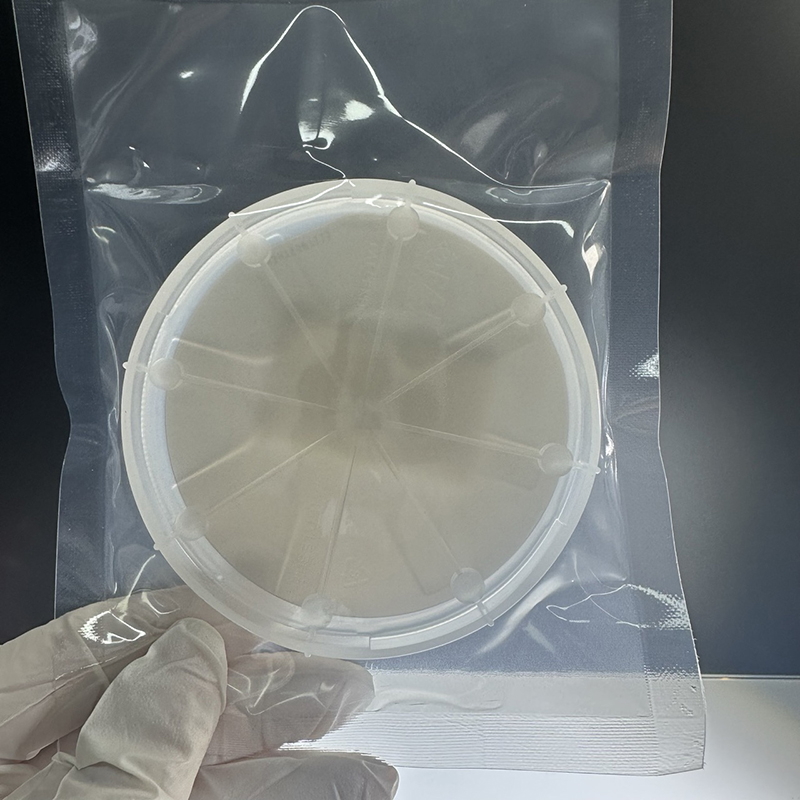

3 inch High Purity (Undoped) Silicon Carbide Wafers semi-Insulating Sic Substrates (HPSl)

Thepa

1. Thepa ea 'Mele le Sebopeho

● Mofuta oa Boitsebiso: Bohloeki bo Phahameng (Undoped) Silicon Carbide (SiC)

● Bophara: 3 inches (76.2 mm)

● Botenya: 0.33-0.5 mm, e ka khonehang ho latela litlhoko tsa kopo.

● Crystal Structure: 4H-SiC polytype e nang le lesela la hexagonal, e tsejoang ka ho tsamaea ha elektronike e phahameng le botsitso ba mocheso.

●Tsamaiso:

oStandard: [0001] (C-plane), e loketse mefuta e mengata ea likopo.

Ka boikhethelo: Off-axis (4° kapa 8° tilt) bakeng sa kholo e ntlafetseng ea epitaxial ea likarolo tsa lisebelisoa.

● Bophahamo: Kakaretso ea botenya bo fapaneng (TTV) ● Boleng ba Sebaka:

o hloekisitsoe ho ea ho oLow-defect density (<10/cm² tekano ea micropipe). 2. Thepa ea Motlakase ● Resistivity: >109^99 Ω·cm, e hlokometsoeng ka ho felisoa ha li-dopants tse etsoang ka boomo.

● Matla a Dielectric: Mamello e phahameng ea motlakase e nang le tahlehelo e fokolang ea dielectric, e loketseng bakeng sa lisebelisoa tse phahameng tsa matla.

● Thermal Conductivity: 3.5-4.9 W / cm·K, e nolofalletsang ho senya mocheso ka katleho lisebelisoa tse sebetsang hantle.

3. Thermal le Mechanical Thepa

● Wide Bandgap: 3.26 eV, ts'ebetso e tšehetsang tlas'a motlakase o phahameng, mocheso o phahameng, le maemo a phahameng a mahlaseli a kotsi.

● Ho thatafala: Mohs scale 9, ho netefatsa ho tiea khahlanong le ho apara ha mechine nakong ea ts'ebetso.

● Thermal Katoloso Coefficient: 4.2×10−6/K4.2 \times 10^{-6}/\text{K}4.2×10−6/K, ho netefatsa botsitso ba dimensional tlas'a phapang ea mocheso.

| Paramethara | Kereiti ya Tlhahiso | Sehlopha sa Lipatlisiso | Sehlopha sa Dummy | Yuniti |

| Kereiti | Kereiti ya Tlhahiso | Sehlopha sa Lipatlisiso | Sehlopha sa Dummy | |

| Diameter | 76.2 ± 0.5 | 76.2 ± 0.5 | 76.2 ± 0.5 | mm |

| Botenya | 500 ± 25 | 500 ± 25 | 500 ± 25 | µm |

| Wafer Orientation | On-axis: <0001> ± 0.5° | On-axis: <0001> ± 2.0° | On-axis: <0001> ± 2.0° | tekanyo |

| Boima ba Micropipe (MPD) | ≤1 | ≤5 | ≤ 10 | cm−2^-2−2 |

| Ho hanyetsa Motlakase | ≥ 1E10 | ≥ 1E5 | ≥ 1E5 | Ω·cm |

| Dopant | E butsoe | E butsoe | E butsoe | |

| Maemo a Motheo a Flat | {1-100} ± 5.0° | {1-100} ± 5.0° | {1-100} ± 5.0° | tekanyo |

| Bolelele ba Phatlalatso ba Pele | 32.5 ± 3.0 | 32.5 ± 3.0 | 32.5 ± 3.0 | mm |

| Bolelele ba Bokhabane ba Bobeli | 18.0 ± 2.0 | 18.0 ± 2.0 | 18.0 ± 2.0 | mm |

| Boemo ba Bobeli ba Flat | 90 ° CW ho tloha foleteng ea mantlha ± 5.0 ° | 90 ° CW ho tloha foleteng ea mantlha ± 5.0 ° | 90 ° CW ho tloha foleteng ea mantlha ± 5.0 ° | tekanyo |

| Kenyelletso ea Edge | 3 | 3 | 3 | mm |

| LTV/TTV/Bow/Warp | 3/10/±30/40 | 3/10/±30/40 | 5/15/±40/45 | µm |

| Bokhopo ba Sekaho | Si-sefahleho: CMP, C-sefahleho: e hloekisitsoe | Si-sefahleho: CMP, C-sefahleho: e hloekisitsoe | Si-sefahleho: CMP, C-sefahleho: e hloekisitsoe | |

| Cracks (Leseli le Phahameng ka ho Fetisisa) | Ha ho letho | Ha ho letho | Ha ho letho | |

| Hex Plates (Leseli le Phahameng ka ho Fetisisa) | Ha ho letho | Ha ho letho | Sebaka sa Koketso 10% | % |

| Libaka tsa Polytype (Leseli le Phahameng ka ho Fetisisa) | Sebaka sa Koketso 5% | Sebaka sa Koketso 20% | Sebaka sa Koketso 30% | % |

| Mekhoro (Leseli le Matla a Phahameng) | ≤ Mengoallo e 5, bolelele bo akaretsang ≤ 150 | ≤ Mengoallo e 10, bolelele bo akaretsang ≤ 200 | ≤ Mengoallo e 10, bolelele bo akaretsang ≤ 200 | mm |

| Edge Chipping | Ha ho na ≥ 0.5 mm bophara / botebo | 2 e lumelletsoe ≤ 1 mm bophara / botebo | 5 e lumelletsoe ≤ 5 mm bophara / botebo | mm |

| Tšilafalo ea Bokaholimo | Ha ho letho | Ha ho letho | Ha ho letho |

Lisebelisoa

1. Matla a Elektronike

Lekhalo le pharaletseng le tsamaiso e phahameng ea mocheso oa likaroloana tsa HPSI SiC li li etsa hore e be tse loketseng lisebelisoa tsa motlakase tse sebetsang maemong a feteletseng, joalo ka:

● Lisebelisoa tsa High-Voltge: Ho kenyeletsoa MOSFET, IGBTs, le Schottky Barrier Diodes (SBDs) bakeng sa ho fetola matla ka katleho.

● Lisebelisoa tsa Matla a Tsosolositsoeng: Tse kang li-inverters tsa letsatsi le li-control turbine controller.

● Likoloi tsa Motlakase (EVs): Li sebelisoa ho li-inverters, li-charger le litsamaiso tsa motlakase ho ntlafatsa ts'ebetso le ho fokotsa boholo.

2. Likopo tsa RF le Microwave

Tahlehelo e phahameng ea matla le tahlehelo e tlase ea dielectric ea li-wafer tsa HPSI li bohlokoa bakeng sa litsamaiso tsa radio-frequency (RF) le microwave, ho kenyelletsa:

● Setsi sa Mehala ea Khokahano: Liteishene tsa motheo tsa marang-rang a 5G le likhokahano tsa satellite.

● Sefofane le Tšireletso: Lisebelisoa tsa radar, li-antenna tsa mekhahlelo e fapaneng, le likarolo tsa avionics.

3. Optoelectronics

Lekhalo le pepeneneng le le pharaletseng la 4H-SiC le nolofalletsa tšebeliso ea eona ho lisebelisoa tsa optoelectronic, tse kang:

● UV Photodetectors: Bakeng sa tlhokomelo ea tikoloho le tlhahlobo ea bongaka.

● Li-LED tsa Matla a Phahameng: Ho tšehetsa lisebelisoa tsa mabone a tiileng.

● Laser Diodes: Bakeng sa lisebelisoa tsa indasteri le tsa bongaka.

4. Lipatlisiso le Ntlafatso

Li-substrates tsa HPS SiC li sebelisoa haholo li-lab tsa R&D tsa thuto le tsa indasteri bakeng sa ho lekola thepa e tsoetseng pele ea thepa le boqapi ba lisebelisoa, ho kenyelletsa:

● Epitaxial Layer Growth: Lithuto mabapi le ho fokotsa sekoli le ho ntlafatsa lera.

● Lithuto tsa Carrier Mobility: Patlisiso ea lipalangoang tsa elektronike le sekoti ka thepa e hloekileng haholo.

● Prototyping: Tšebeliso ea pele ea lisebelisoa tse ncha le li-circuits.

Melemo

Boleng bo Phahameng:

Bohloeki bo phahameng le bofokoli bo fokolang bo fana ka sethala se ka tšeptjoang bakeng sa likopo tse tsoetseng pele.

Thermal Stability:

Lintho tse ntle tsa ho senya mocheso li lumella lisebelisoa hore li sebetse ka katleho tlas'a matla a phahameng le maemo a mocheso.

Tšebelisano e Batsi:

Mekhoa e fumanehang le likhetho tsa botenya ba tloaelo li netefatsa ho ikamahanya le maemo bakeng sa litlhoko tse fapaneng tsa lisebelisoa.

Nako e telele:

Ho thatafala ho ikhethang le botsitso ba sebopeho ho fokotsa ho roala le ho senyeha nakong ea ts'ebetso le ts'ebetso.

Mefuta-futa:

E loketse mefuta e mengata ea liindasteri, ho tloha ho matla a tsosolositsoeng ho ea ho aerospace le mehala ea puisano.

Qetello

Sephaphatha sa 3-inch High Purity Semi-Insulating Silicon Carbide se emela tlhōrō ea thekenoloji ea substrate bakeng sa lisebelisoa tse matla, tse phahameng le tsa optoelectronic. Motsoako oa eona oa thepa e ntle haholo ea mocheso, motlakase le mochini o netefatsa ts'ebetso e tšepahalang libakeng tse thata. Ho tloha ho lisebelisoa tsa elektronike tsa matla le litsamaiso tsa RF ho ea ho optoelectronics le R&D e tsoetseng pele, li-substrates tsena tsa HPSI li fana ka motheo oa lintlafatso tsa hosane.

Ho fumana lintlha tse ling kapa ho etsa odara, ka kopo ikopanye le rona. Sehlopha sa rona sa tekheniki se teng ho fana ka tataiso le likhetho tsa ho iketsetsa tse tsamaellanang le litlhoko tsa hau.

Setšoantšo se qaqileng