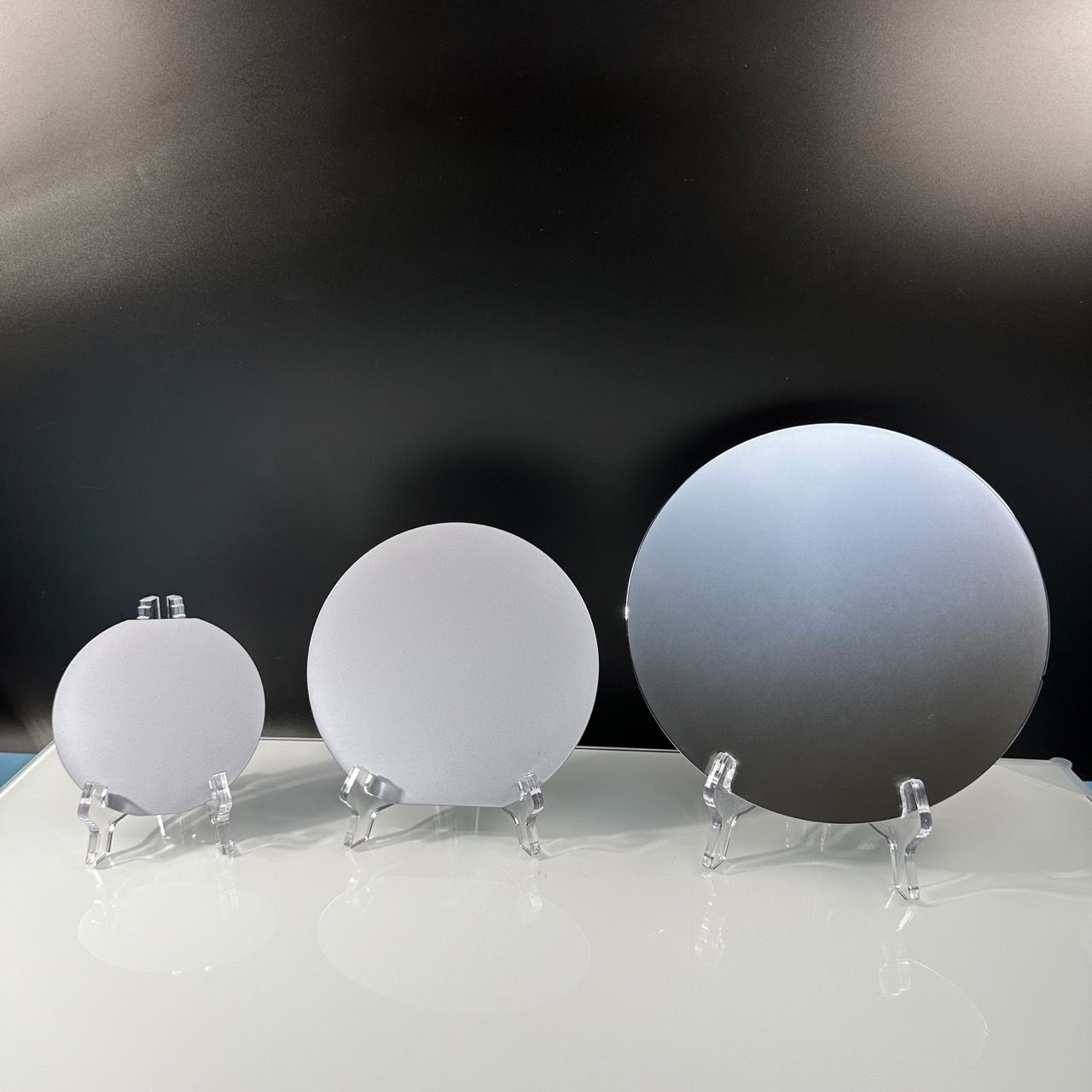

4inch Silicon wafer FZ CZ N-Type DSP kapa SSP Test grade

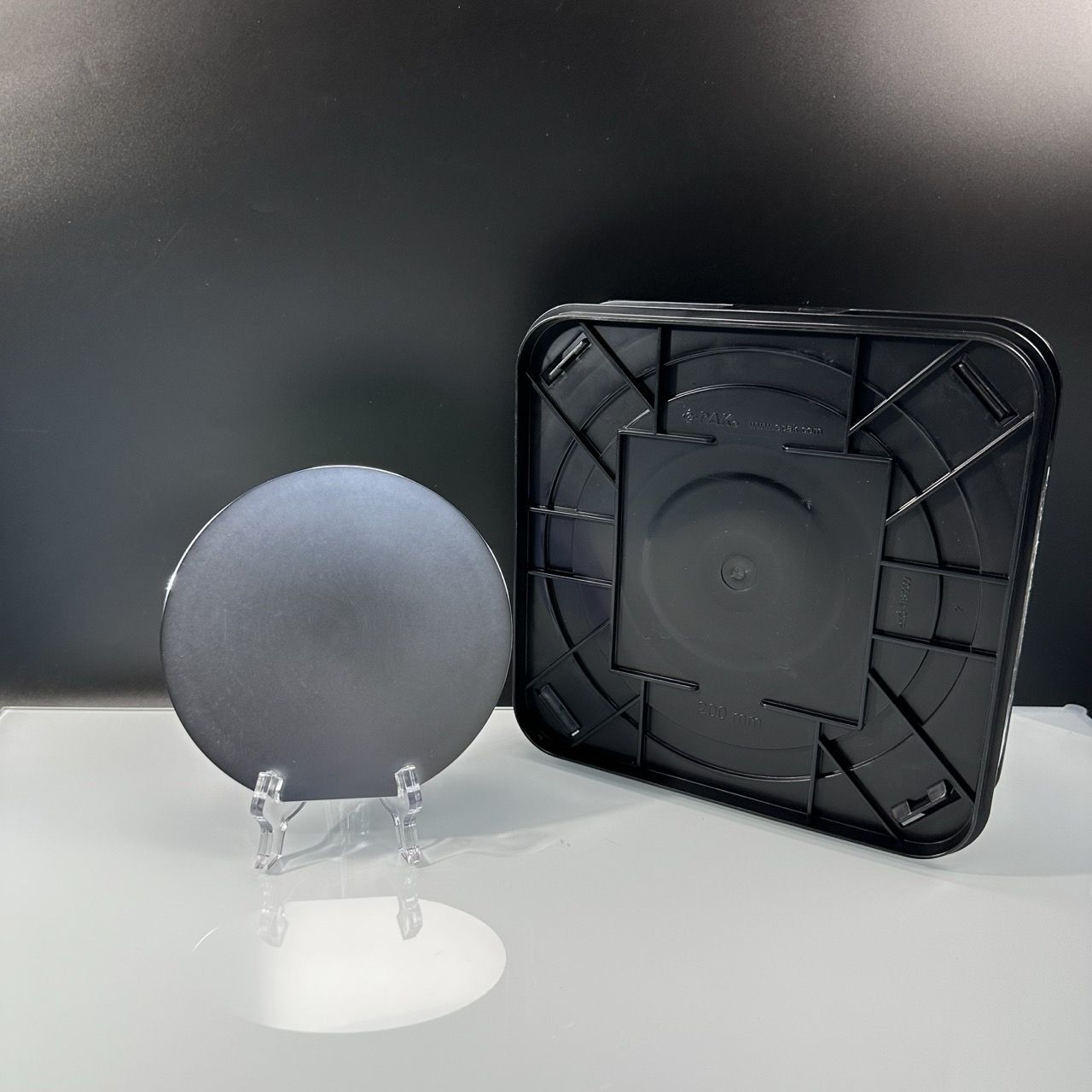

Hlahisa lebokose la wafer

Li-wafers tsa silicon ke karolo ea bohlokoa ea lefapha la theknoloji le ntseng le hola kajeno. Mmaraka oa lisebelisoa tsa semiconductor o hloka li-wafers tsa silicon tse nang le litlhaloso tse nepahetseng ho hlahisa palo e kholo ea lisebelisoa tse ncha tse kopaneng tsa potoloho. Rea hlokomela hore ha litšenyehelo tsa tlhahiso ea semiconductor li ntse li eketseha, le litšenyehelo tsa thepa eo ea tlhahiso, joalo ka li-wafers tsa silicon. Re utloisisa bohlokoa ba boleng le katleho ea litšenyehelo lihlahisoa tseo re li fang bareki ba rona. Re fana ka li-wafers tse bolokang chelete e ngata le tsa boleng bo tsitsitseng. Haholo-holo re hlahisa li-wafers tsa silicon le li-ingots (CZ), li-wafers tsa epitaxial, le li-wafers tsa SOI.

| Diameter | Diameter | E bentšitsoe | Qheletsoe | Boitloaelo | Resistivity/Ω.cm | Botenya/um |

| 2inch | 50.8±0.5mm | SSP DSP | P/N | 100 | 1-20 | 200-500 |

| 3 intshi | 76.2±0.5mm | SSP DSP | P/B | 100 | NA | 525±20 |

| 4inch | 101.6±0.2 101.6±0.3 101.6±0.4 | SSP DSP | P/N | 100 | 0.001-10 | 200-2000 |

| 6 intshi | 152.5±0.3 | SSPDSP | P/N | 100 | 1-10 | 500-650 |

| 8inch | 200±0.3 | DSPSSP | P/N | 100 | 0.1-20 | 625 |

Tšebeliso ea li-wafers tsa silicon

Substrate: PECVD/LPCVD coating, magnetron sputtering

Substrate: XRD, SEM, atomic force infrared spectroscopy, transmission electron microscopy, fluorescence spectroscopy le liteko tse ling tsa analytical, molecular beam epitaxial growth, X-ray analysis of crystal microstructure processing: etching, bonding, lisebelisoa tsa MEMS, lisebelisoa tsa motlakase, lisebelisoa tsa MOS le ts'ebetso e 'ngoe.

Ho tloha ka 2010, Shanghai XKH Material Tech. Co., Ltd e ikemiselitse ho fa bareki litharollo tse felletseng tsa 4-inch Silicon Wafer, ho tloha ho li-wafers tsa boemo ba debugging Dummy Wafer, liphaephe tsa liteko tsa liteko, ho isa lihlahisoa tsa boemo ba sehlahisoa Prime Wafer, hammoho le liphaephe tse khethehileng, Oxide wafers Oxide, Nitride wafers Si3N4, Aluminium plated wafer, MEMS Glass, li-wafers tse entsoeng ka botenya haholo le tse bataletseng haholo, joalo-joalo, tse nang le boholo bo tlohang ho 50mm-300mm, 'me re ka fana ka liphaphatha tsa semiconductor tse nang le mahlakore a le mong / a mabeli a bentšitsoeng, ho fokotsa, ho cheka, MEMS le litšebeletso tse ling tsa ho lokisa le ho li etsa.

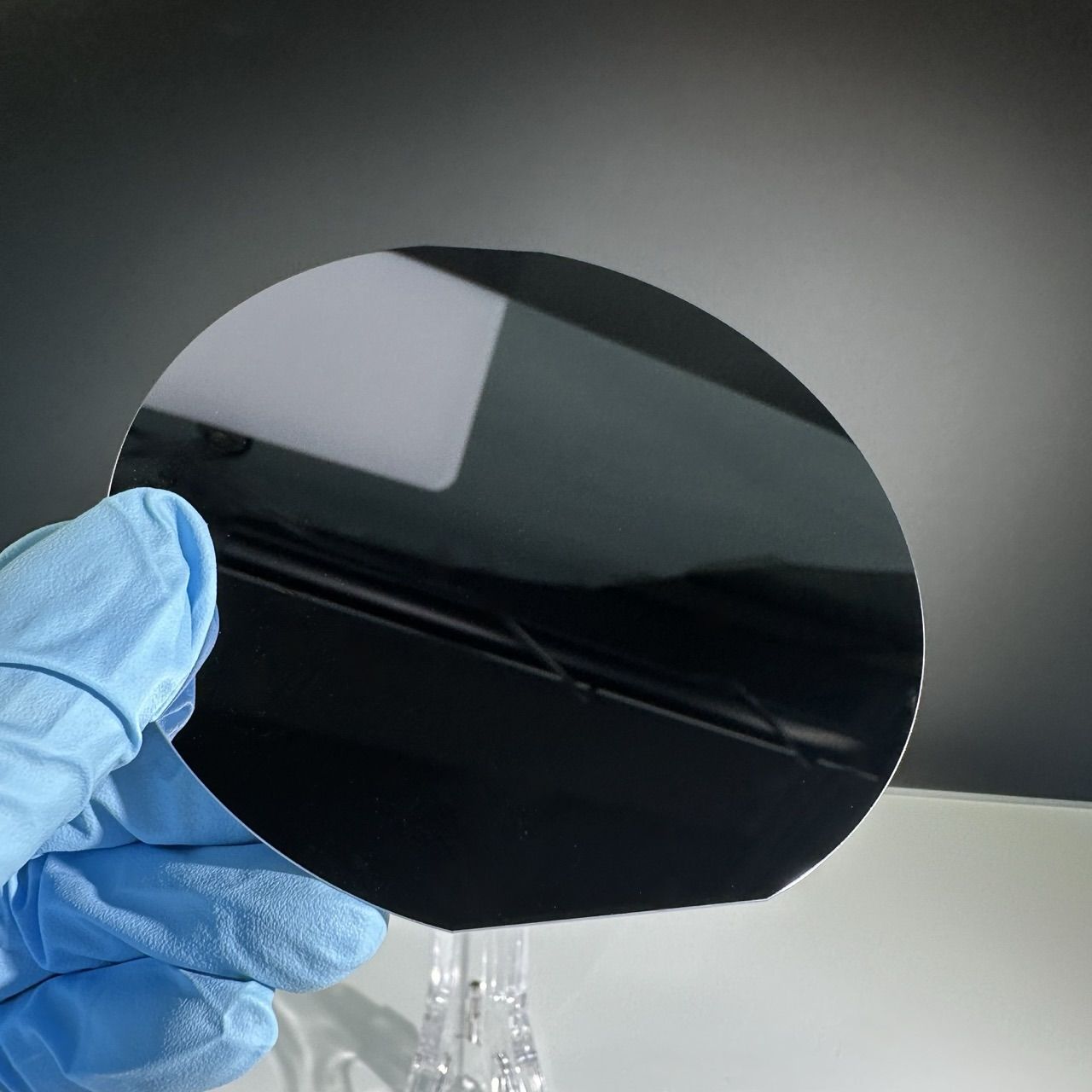

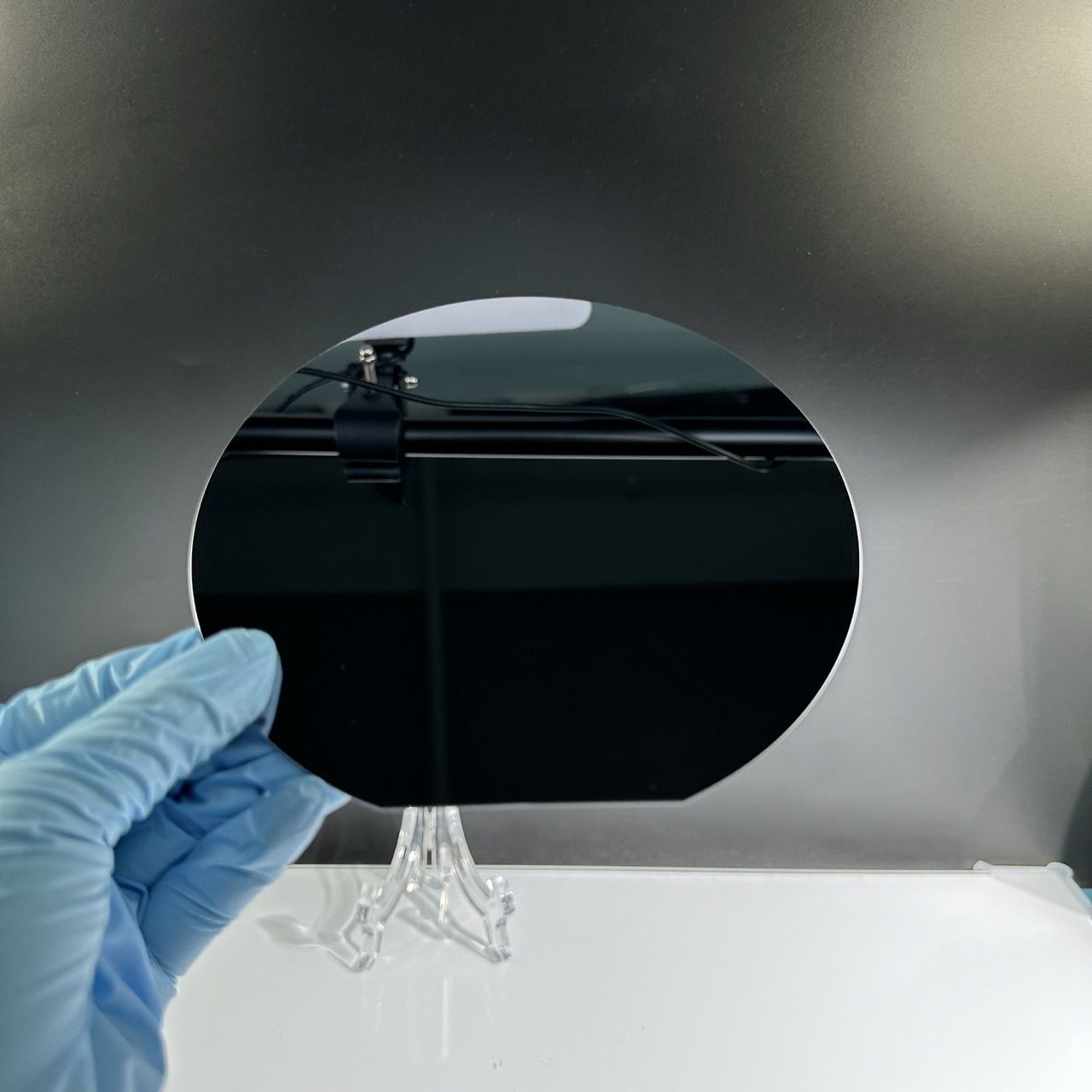

Setšoantšo se qaqileng