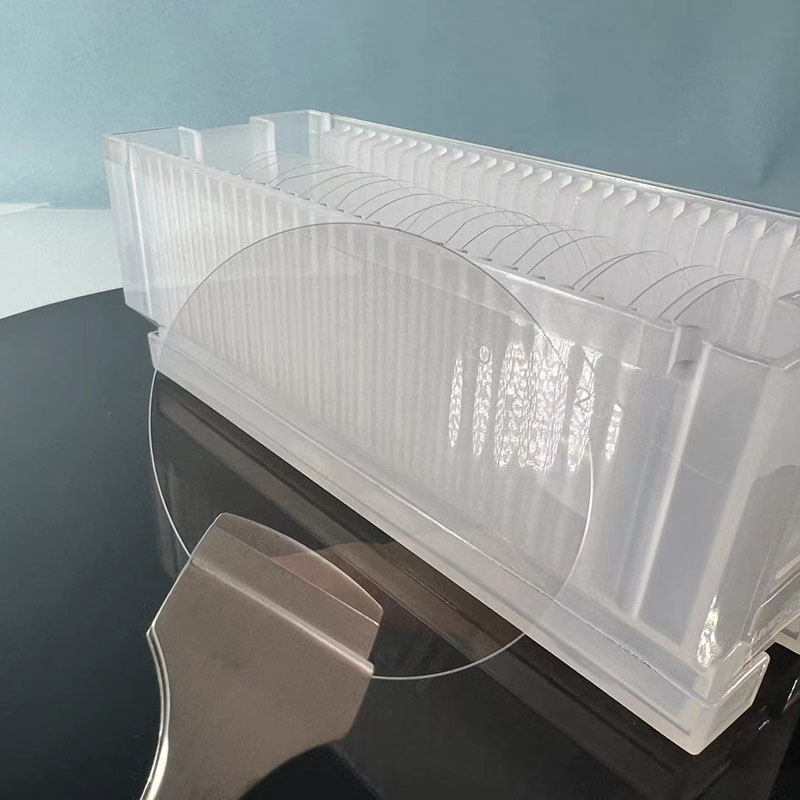

Bionic non-slip pad wafer e nang le vacuum sucker sucker friction pad sucker

Likarolo tsa bionic anti-slip pad:

• Tšebeliso ea lisebelisoa tse khethehileng tsa boenjiniere tsa elastomer, ho finyella ho se na masala, phello e hloekileng ea anti-skid e se nang tšilafalo, e loketseng litlhoko tsa tikoloho ea tlhahiso ea semiconductor.

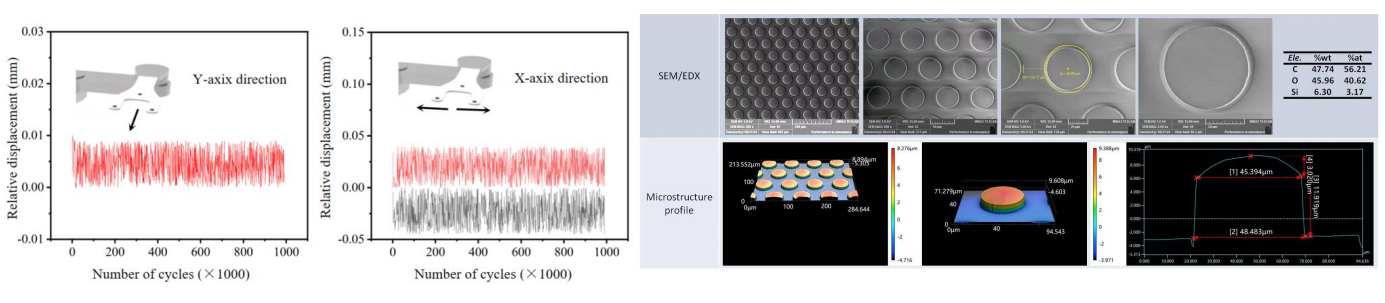

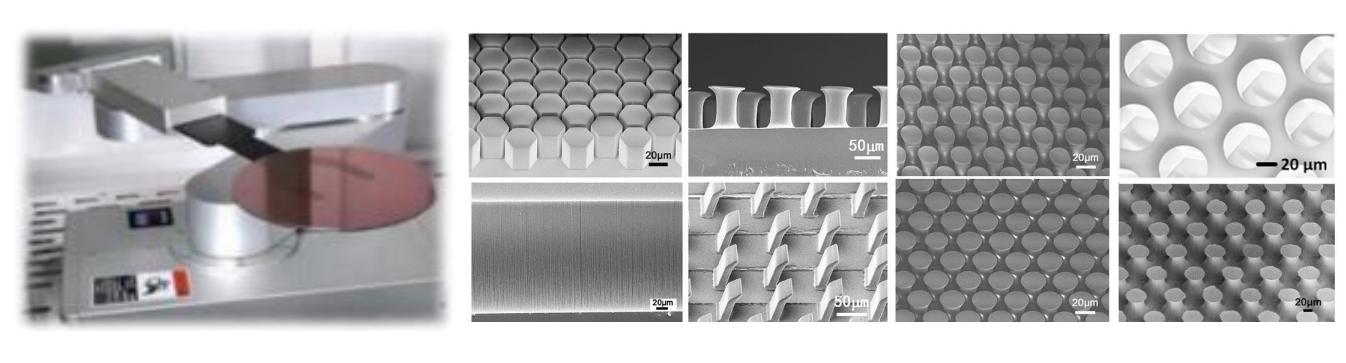

• Ka mokhoa o nepahetseng oa sebopeho sa sebopeho sa micro-nano, taolo e bohlale ea litšoaneleho tsa ho ferekana ha holim'a metsi, ha u ntse u boloka coefficient e phahameng ea likhohlano ha u ntse u finyella li-ultra-low adhesion.

• Moralo o ikhethileng oa mokhoa oa ho sebetsa o thusa ts'ebetso e ntle haholo ea khohlano e phahameng ea tangential (μ>2.5) le ho khomarela ho tlase ho tloaelehileng (<0.1N/cm²).

• Lisebelisoa tsa polymer tse entsoeng ka ho khetheha bakeng sa indasteri ea semiconductor, e finyellang ts'ebetso e tsitsitseng ntle le ho fokotsa tšebeliso ea 100,000 ka theknoloji ea tlhahiso ea micro le nano.

Sesebelisoa sa Bionic anti-slip pad:

(1) Indasteri ea semiconductor

1. Ho etsa liphaephe:

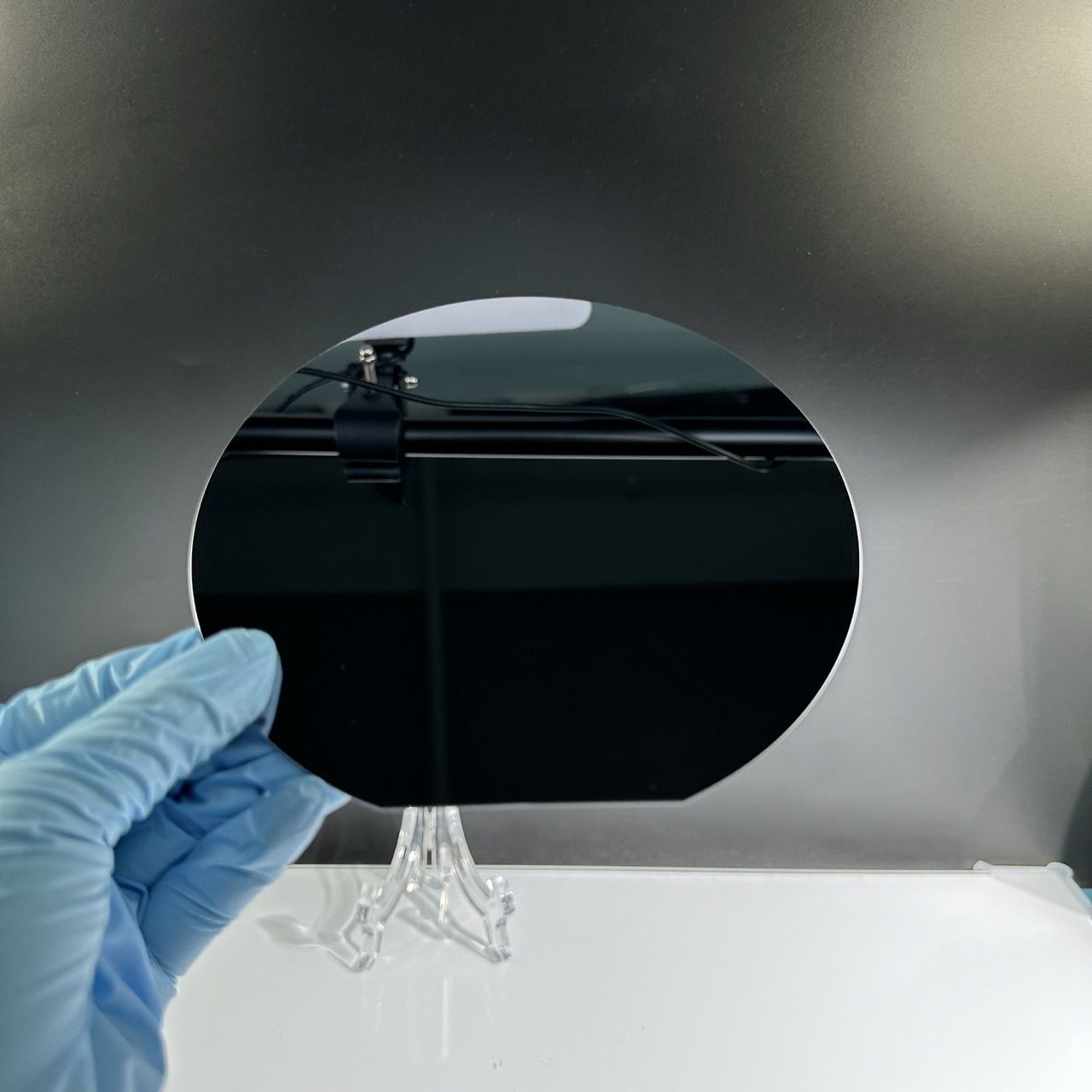

* Maemo a sa thelleng nakong ea phetisetso ea li-wafers tse tšesaane tse fihlang ho li-inch tse 12 (50-300μm)

· Tokiso e nepahetseng ea sejari sa liphaphatha tsa mochini oa lithography

· Wafer non-slip liner bakeng sa lisebelisoa tsa tlhahlobo

2. Teko ea sephutheloana:

· Tokiso e sa senyeheng ea lisebelisoa tsa matla tsa silicon carbide/gallium nitride

• Anti-slip buffer nakong ea ho kenya chip

· Lekola ts'ohanyetso le ho thella ha tafole ea probe

(2) Indasteri ea photovoltaic

1. Ho sebetsa ha silicon wafer:

· Ho lokisa ho se thelle nakong ea ho itšeha ha molamu oa monocrystalline silicon

· Ultra-thin silicon wafer (<150μm) phetiso e sa thelleheng

· Sebaka sa silicon wafer sa mochini o hatisang skrineng

2. Kopano ea likarolo:

· Glass backplane laminated e sa thellang

· Foreimi tlhomamiso boemo

· Lebokose le tlamang le tsitsitse

(3) indasteri ea motlakase

1. Phanele ea ponts'o:

· Ts'ebetso ea substrate ea khalase ea OLED / LCD e sa thekeseleng

· Boemo bo nepahetseng ba polarizer fit

· Thepa e sa keneng ho thothomela le lisebelisoa tsa tlhahlobo ea skid-proof

2. Likarolo tsa Optical:

· Kopano ea module ea lense e sa thellang

· Ho lokisa prism / seipone

· Shock-proof laser optical system

(4) Lisebelisoa tse nepahetseng

1. Sethala se nepahetseng sa mochine oa lithography se khahlanong le ho thella

2. Tafole ea ho lekanya ea lisebelisoa tsa ho lemoha ha e na ho tšoha

3. Thepa e ikemetseng ea letsoho e sa thelleng

Lintlha tsa tekheniki:

| Sebopeho sa thepa: | C, O, Si |

| Ho thatafala ha lebopo (A) : | 50 ~ 55 |

| Elastic recovery coefficient: | 1.28 |

| Mocheso o phahameng oa mamello: | 260 ℃ |

| Friction coefficient: | 1.8 |

| Khanyetso ea PLASMA: | Mamello |

Litšebeletso tsa XKH:

XKH e fana ka lits'ebeletso tse felletseng tsa ts'ebetso ea bionic anti-slip mat, ho kenyeletsoa tlhahlobo ea tlhokahalo, moralo oa moralo, bopaki bo potlakileng le ts'ehetso ea tlhahiso ea bongata. E itšetlehile ka theknoloji ea tlhahiso ea micro le nano, XKH e fana ka litharollo tsa litsebi tse thibelang ho thella bakeng sa indasteri ea semiconductor, photovoltaic le photoelectric, 'me e atlehile ho thusa bareki ho finyella liphello tse kholo tse kang ho fokotsa sekhahla sa litšila ho 0.005% le keketseho ea lihlahisoa ka 15%.

Setšoantšo se qaqileng