Mochini o phahameng oa ho cheka Laser oa ho cheka ka laser ho itšeha

Likarolo tsa Bohlokoa

Ultra-Fine Laser Spot Focusing

E sebelisa katoloso ea maballo le li-optics tse lebisang phetiso e phahameng ho fihlela boholo ba matheba a micron kapa submicron, ho netefatsa matla a matla le ho sebetsa ka nepo.

Sistimi ea Taolo e Bohlale

E tla le PC ea indasteri le software e inehetseng ea graphical interface e tšehetsang ts'ebetso ea lipuo tse ngata, tokiso ea paramethara, pono ea lithulusi, tlhahlobo ea nako ea nnete, le tlhokomeliso ea liphoso.

Auto Programming Bokhoni

E ts'ehetsa ho kenngoa ha G-code le CAD ka mokhoa oa boiketsetso bakeng sa meaho e rarahaneng e hlophisitsoeng le e hlophisitsoeng, e tsamaisang lipeipi tsa moralo ho isa tlhahiso.

Liparamente tse Customizable ka ho Fetisisa

E lumella ho itlhophisa ha liparamente tsa bohlokoa joalo ka bophara ba lesoba, botebo, sekhutlo, lebelo la ho skena, maqhubu, le bophara ba molumo bakeng sa lisebelisoa tse fapaneng le botenya.

Sebaka se Ametsoeng ke Mocheso o Nyenyane (HAZ)

E sebelisa li-laser tse khutšoane kapa tsa ultrashort pulse (ka boikhethelo) ho hatella phallo ea mocheso le ho thibela mats'oao a ho cha, mapatso, kapa tšenyo ea sebopeho.

Mothati oa Motion oa XYZ o Phahameng ka ho Fetisisa

E na le li-module tsa motsamao tse nepahetseng tsa XYZ tse nang le ho pheta-pheta <± 2μm, ho netefatsa botsitso le ho nepahala ha sebopeho sa microstructuring.

Tikoloho Ho ikamahanya le maemo

E loketse ka bobeli tikoloho ea liindasteri le ea laboratori ka maemo a nepahetseng a 18°C–28°C le 30%–60% ea mongobo.

Phepelo ea Motlakase e Eketsehileng

Motlakase o tloaelehileng oa 220V / 50Hz / 10A, o tsamaellanang le litekanyetso tsa motlakase tsa Chaena le tsa machaba bakeng sa botsitso ba nako e telele.

Libaka tsa Kopo

Diamond Wire Drawing Die Drilling

E fana ka li-micro-hole tse chitja, tse fetolehang habonolo tse nang le taolo e nepahetseng ea bophara, e ntlafatsa haholo bophelo ba lefu le ho tsitsa ha sehlahisoa.

Micro-Perforation bakeng sa Li-Silencers

E sebetsana le li-micro-perforation tse teteaneng le tse ts'oanang tsa lisebelisoa tsa tšepe kapa tse kopantsoeng, tse loketseng lisebelisoa tsa likoloi, sefofane le matla.

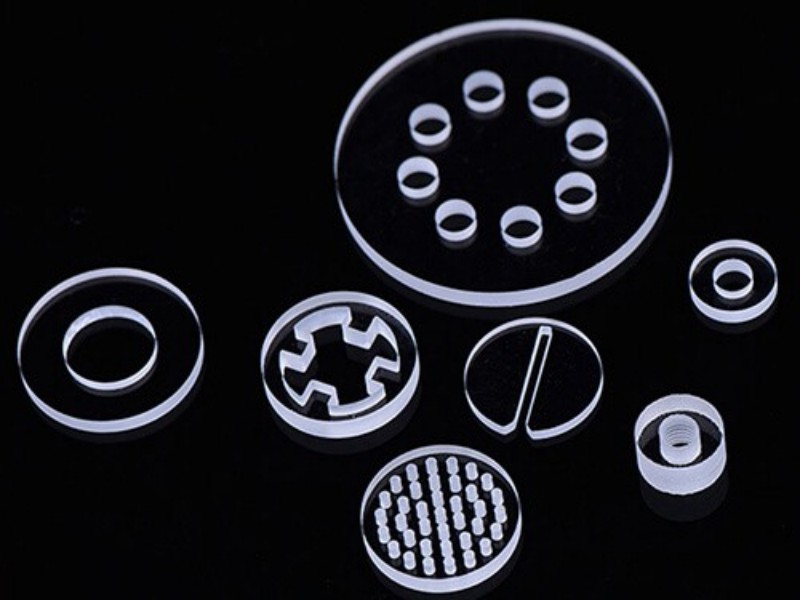

Micro-Cutting ea Superhard Materials

Mahlaseli a laser a matla a phahameng a sehile PCD, safire, lirafshoa, le lisebelisoa tse ling tse thata tse thata tse nang le lintlha tse phahameng, tse se nang burr.

Microfabrication bakeng sa R&D

E loketse liunivesithi le litsi tsa lipatlisiso ho etsa li-microchannel, li-microneedles, le meaho e menyenyane ea mahlo ka tšehetso bakeng sa nts'etsopele e ikhethileng.

Q&A

Q1: Ke lisebelisoa life tse ka tsamaisoang ke sistimi?

A1: E tšehetsa ts'ebetso ea taemane ea tlhaho, PCD, safire, tšepe e sa hloekang, lirafshoa, likhalase, le lisebelisoa tse ling tse thata haholo kapa tse phahameng haholo.

Q2: Na e tšehetsa ho cheka holim'a 3D?

A2: Mojule oa boikhethelo oa 5-axis o ts'ehetsa machining a rarahaneng a 3D, a loketseng likarolo tse sa tloaelehang joalo ka hlobo le mahare a turbine.

Q3: Na mohloli oa laser o ka nkeloa sebaka kapa oa etsoa?

A3: E ts'ehetsa ho nkela sebaka ka matla a fapaneng kapa li-laser tsa wavelength, joalo ka li-laser tsa fiber kapa li-laser tsa femtosecond/picosecond, tse lokisehang ho latela litlhoko tsa hau.

Q4: Nka fumana ts'ehetso ea tekheniki le ts'ebeletso ea morao-rao ea thekiso joang?

A4: Re fana ka tlhahlobo ea hole, tlhokomelo ea sebakeng sa marang-rang, le likarolo tse ling tse ncha. Litsamaiso tsohle li kenyelletsa waranti e felletseng le liphutheloana tsa tšehetso ea tekheniki.

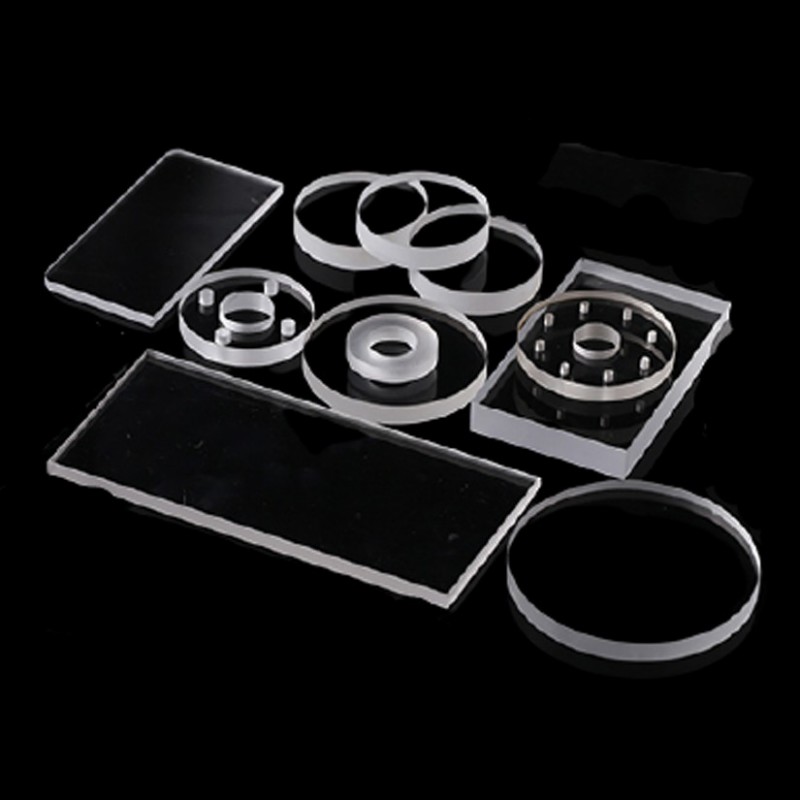

Setšoantšo se qaqileng