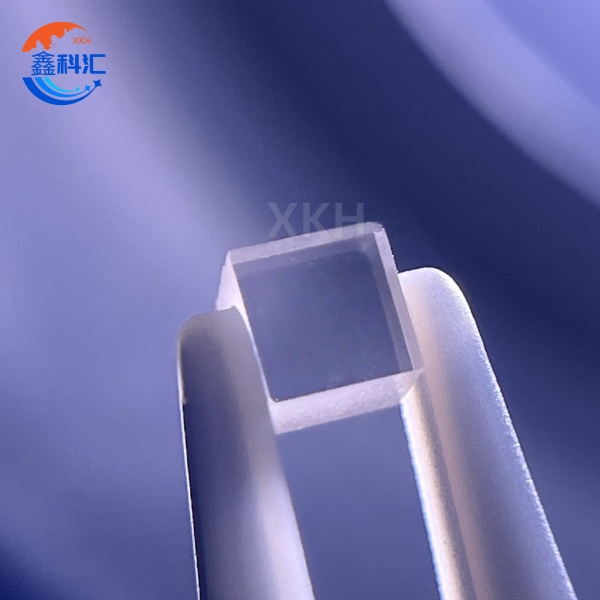

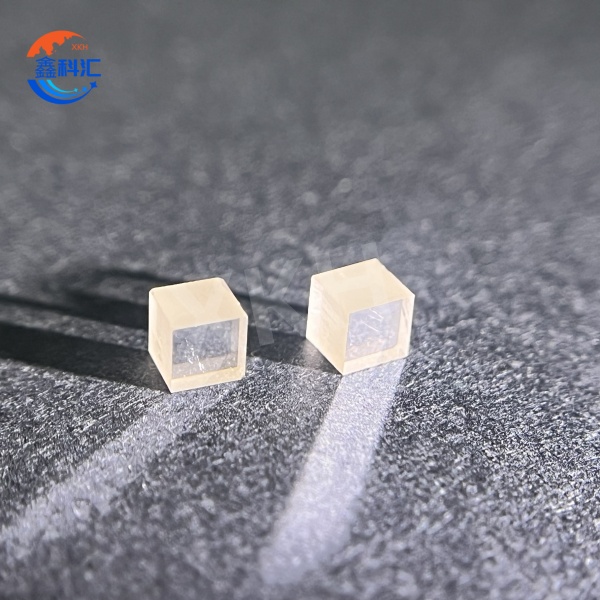

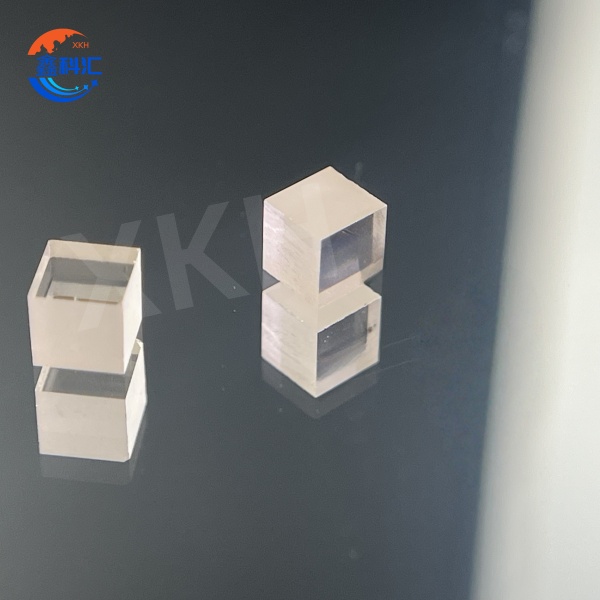

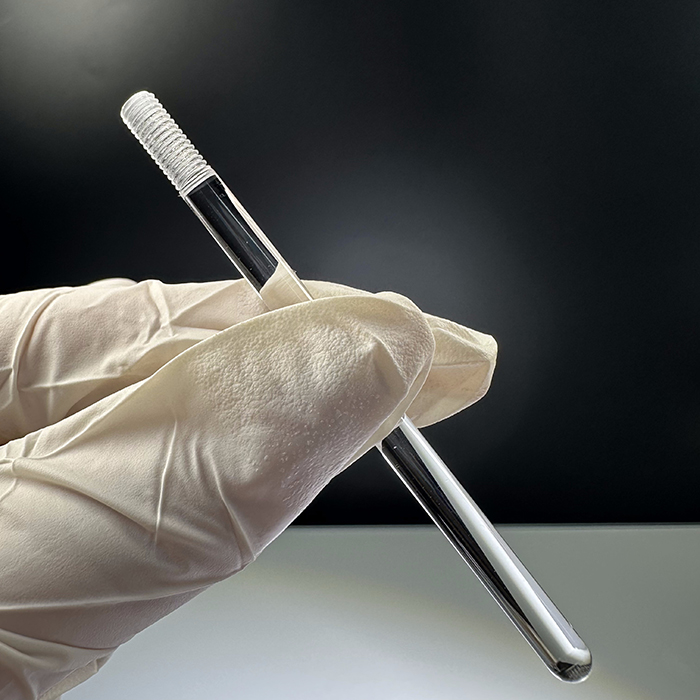

Phahameng Purity SiC Optical Lense Cubic 4H-semi 6SP Size Customized

Litšobotsi tsa SiC Optical Lense

1. Bohlokoa ba Lintho

Boemo bo Feteletseng ba Tikoloho: E mamella mocheso >1500°C, kutu e matla ea asiti/alkali, le mahlaseli a matla a phahameng, a loketseng lifofa-sebakeng le lisebelisoa tsa nyutlelie.

Matla a Ikhethileng a Mechini: Ho thatafala ha daemane e haufi (Mohs 9.5), matla a feto-fetohang> 400 MPa, le ho hanyetsa tšusumetso ho feta likhalase tse tloaelehileng tsa optical.

Thermal Stability: Thermal conductivity 100 × e phahameng ho feta silika e kopantsoeng, e nang le CTE feela 1/10 ea khalase e tloaelehileng, e netefatsang botsitso tlas'a libaesekele tse potlakileng tsa mocheso.

2. Optical Performance Melemo

Phetiso e pharaletseng ea spectral (0.2-6 μm); Liaparo tse khethehileng li ka ntlafatsa phetisetso ho> 95% ka lihlopha tse ikhethileng (mohlala, 3-5 μm bohareng ba IR).

Tahlehelo e fokolang ea ho hasana (<0.5%/cm), qetello ea holimo ho fihlela ho 10/5 scratch-dig standard, le flatness ea holim'a λ/10@633 nm.

High laser-induced damage threshold (LIDT) > 15 J/cm² (1064 nm, 10 ns pulses), e loketseng lits'ebetso tse shebaneng le matla a phahameng a laser.

3. Bokhoni ba ho sebetsa ka mokhoa o nepahetseng

E tšehetsa libaka tse rarahaneng (aspheric, freeform) ka ho nepahala ha foromo <100 nm PV le centration <1 arcmin.

E khona ho etsa lilense tsa SiC tse boholo bo boholo (bophara> 500 mm) bakeng sa libonela-hōle tsa linaleli le li-optics tsa sebaka.

Lisebelisoa tsa mantlha tsa SiC Optical Lens

1. Space Optics & Tšireletso

Lilense tsa satellite tsa remote le libonela-hōle tsa sepakapaka, tse matlafatsang thepa ea SiC e bobebe (tekanyo ea 3.21 g/cm³) le ho hanyetsa mahlaseli.

Lifensetere tsa mahlo tsa "missile search", tse mamellang mocheso oa moea (> 1000 ° C) nakong ea sefofane sa hypersonic.

2. Lisebelisoa tsa Laser tse Matla a Phahameng

Lilense tse tsepamisitseng maikutlo bakeng sa lisebelisoa tsa laser tsa indasteri tse sehang / tjheseletsa, tse bolokang nako e telele ho li-laser tse tsoelang pele tsa kW-class.

Beam shaping elements in inertial confinement fusion system (ICF) system, e netefatsang phetiso e nepahetseng ea laser ea matla a phahameng.

3. Semiconductor & Precision Manufacturing

SiC mirror substrates bakeng sa EUV lithography optics, e nang le thermal deformation <1 nm tlasa 10 kW/m² mocheso o phallang.

Lilense tsa motlakase bakeng sa lisebelisoa tsa tlhahlobo ea e-beam, tse sebelisang tsamaiso ea SiC bakeng sa taolo e sebetsang ea mocheso.

4. Tlhahlobo ea Liindasteri le Matla

Lilense tsa Endoscope bakeng sa libopi tsa mocheso o phahameng (1500°C ts'ebetso e tsoelang pele).

Lisebelisoa tsa infrared optical bakeng sa lisebelisoa tsa ho rema liliba tsa oli, ho hanela likhatello tse tlase (> 100 MPa) le mecha ea litaba e senyang.

Melemo e ka Sehloohong ea Tlholisano

1. Boetapele ba Ts'ebetso bo Felletseng

Lilense tsa SiC li feta lisebelisoa tsa khale tsa optical (silica e kopantsoeng, ZnSe) ka botsitso ba mocheso / mochine / lik'hemik'hale, ka thepa ea bona ea "conductivity e phahameng + e tlaase" e rarollang mathata a ho senyeha ha mocheso ho li-optics tse kholo.

2. Lifecycle Cost Effective

Le hoja litšenyehelo tsa pele li phahame, bophelo bo atolositsoeng ba tšebeletso ea lilense tsa SiC (5-10× khalase e tloaelehileng) le ts'ebetso e sa lefelloeng ea tlhokomelo e fokotsa haholo litšenyehelo tsohle tsa botho (TCO).

3. Tokoloho ea Moqapi

Mekhoa ea ho itšoara kapa ea CVD e nolofalletsa mekhoa e bonolo ea SiC optical (li-honeycomb cores), ho finyella litekanyo tsa boima ba boima bo ke keng ba lekanngoa.

XKH Bokhoni ba Tšebeletso

1. Custom Manufacturing Services

Litharollo tsa ho qetela ho tloha ho moralo oa optical (Zemax/Code V simulation) ho isa phepelong ea ho qetela, e tšehetsang libaka tsa aspheric/off-axis parabolic freeform.

Liaparo tse khethehileng: anti-reflection (AR), carbon-like carbon (LIDT> 50 J/cm²), conductive ITO, joalo-joalo.

2. Mekhoa ea Tiisetso ea Boleng

Lisebelisoa tsa Metrology tse kenyelletsang li-interferometers tsa 4D le li-profilers tse khanyang tse tšoeu tse netefatsang λ/20 ho nepahala ha holim'a metsi.

QC ea boemo ba thepa: Tlhahlobo ea sebopeho sa XRD crystallographic bakeng sa SiC e 'ngoe le e 'ngoe e se nang letho.

3. Litšebeletso tse Ekelitsoeng Boleng

Thermo-structural coupling analysis (ANSYS simulation) bakeng sa ho bolela esale pele tshebetso.

Moralo o kopantsoeng oa ntlafatso ea lense ea SiC.

Qetello

Lilense tsa SiC li hlalosa bocha meeli ea ts'ebetso ea lisebelisoa tse phahameng tsa optical ka thepa ea tsona e ke keng ea bapisoa. Bokhoni ba rona bo kopaneng ba ho kopanya thepa ea SiC, ho sebetsa ka nepo, le liteko li fana ka litharollo tsa phetoho ea pono bakeng sa mafapha a sefofane le a tsoetseng pele a indasteri. Ka tsoelo-pele ea kholo ea kristale ea SiC, nts'etsopele ea nako e tlang e tla shebana le li-apertures tse kholoanyane (> 1m) le li-geometri tse thata tsa holim'a metsi (li-arrays tsa mahala).

E le moetsi ea ka sehloohong oa lisebelisoa tse tsoetseng pele tsa optical, XKH e sebetsa ka ho khetheha ka thepa e sebetsang hantle ho kenyeletsa sapphire, silicon carbide (SiC), le li-wafers tsa silicon, tse fanang ka litharollo tsa ho qetela ho tloha ho sebetsa ka thepa e tala ho fihlela qetellong. Setsebi sa rona se kenyelletsa:

1. Tlhahiso e Tloaelehileng: Ho sebetsa ka nepo ha lijeometri tse rarahaneng (aspheric, freeform) tse nang le mamello ho ± 0.001mm

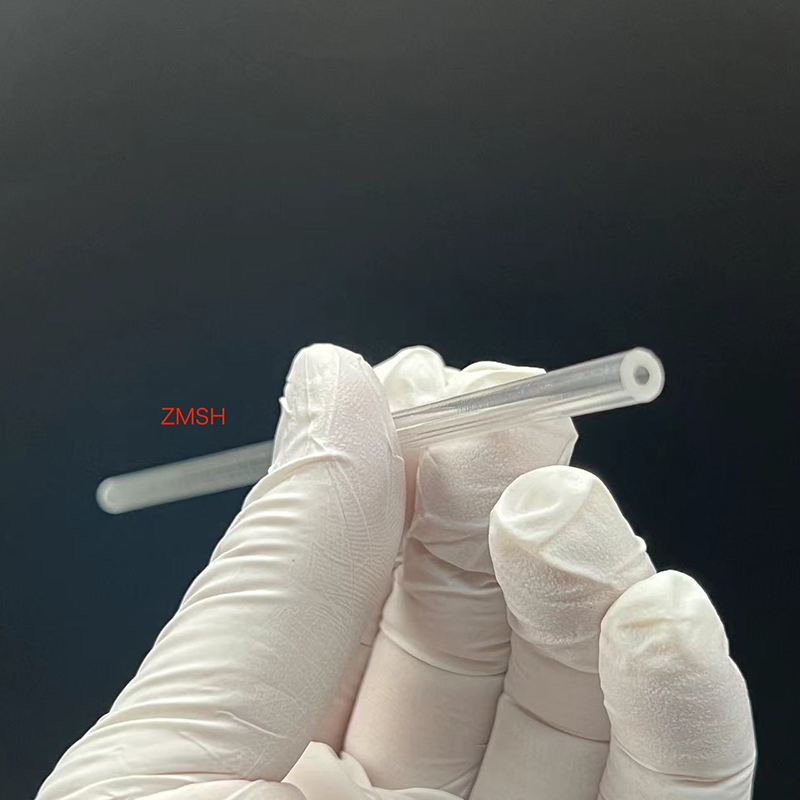

2. Phetoho ea Lintho Tse Ngata: Ho sebetsa safire (UV-IR lifensetere), SiC (high-power optics), le silicon (IR/micro-optics)

3. Litšebeletso tsa Keketso ea Boleng:

Liaparo tse thibelang ponahalo / tse tšoarellang (UV-FIR)

Metrology-backed quality assurance (λ/20 flatness)

Kopano ea likamore tse hloekileng bakeng sa lits'ebetso tse sa utloeng tšilafalo

Re sebeletsa liindasteri tsa aerospace, semiconductor, le laser, re kopanya tsebo ea mahlale a mahlale le tlhahiso e tsoetseng pele ho fana ka lisebelisoa tsa mahlo tse mamellang maemo a feteletseng ha re ntse re ntlafatsa ts'ebetso ea mahlo.