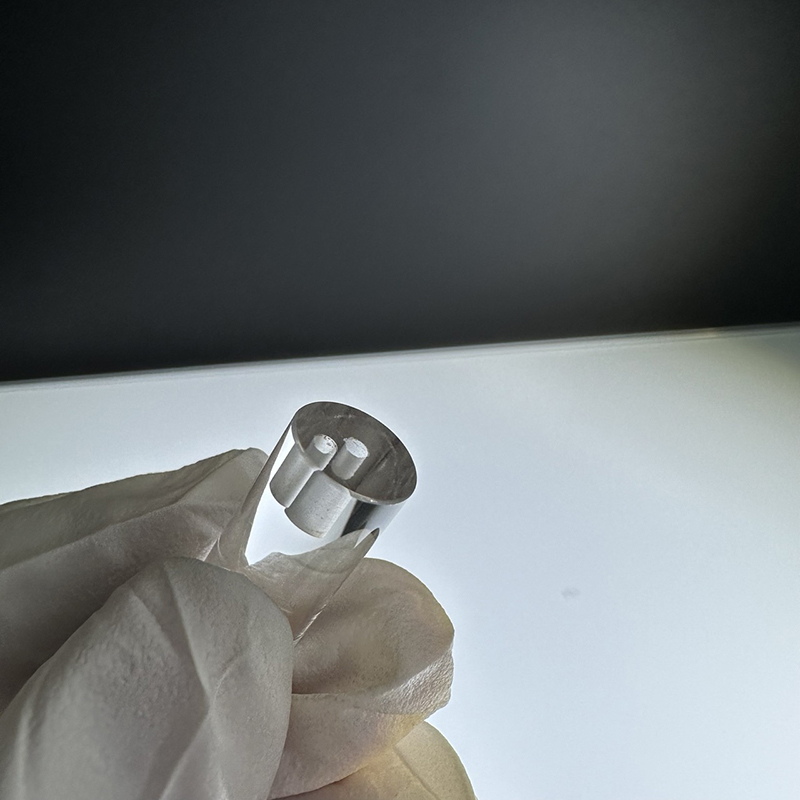

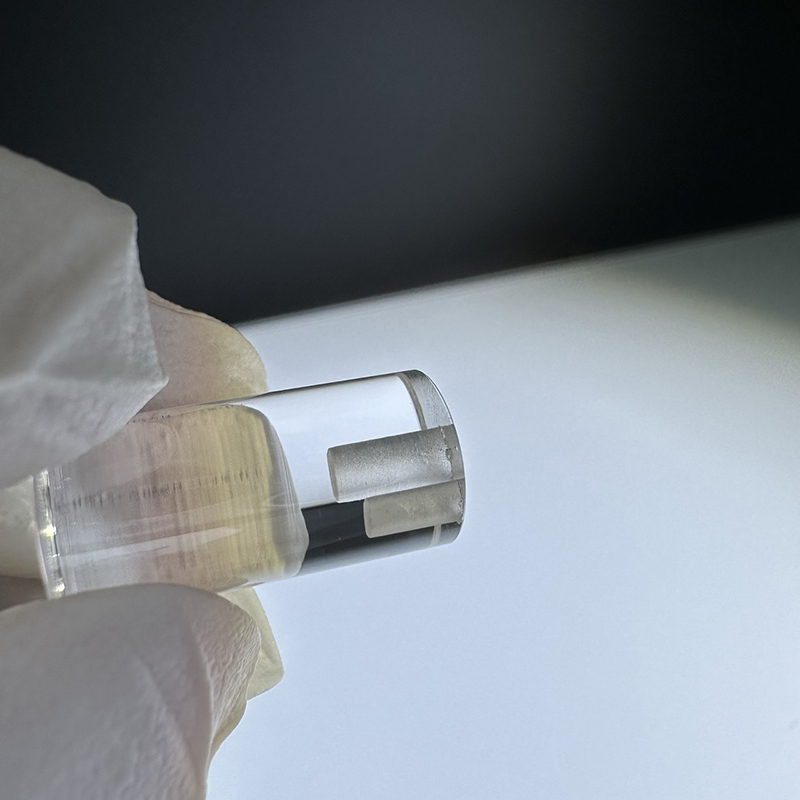

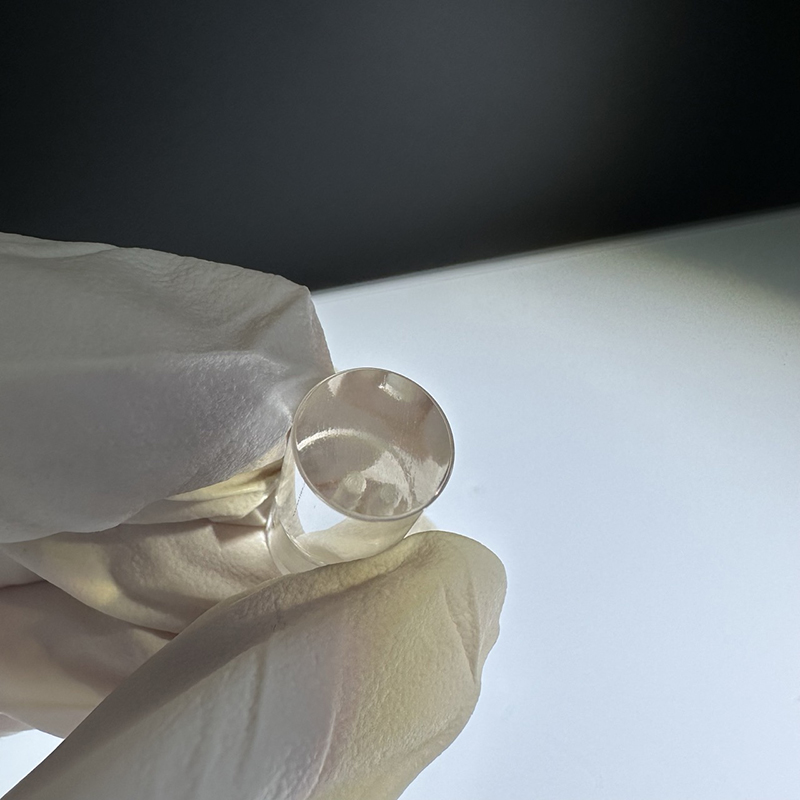

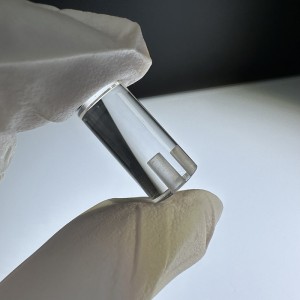

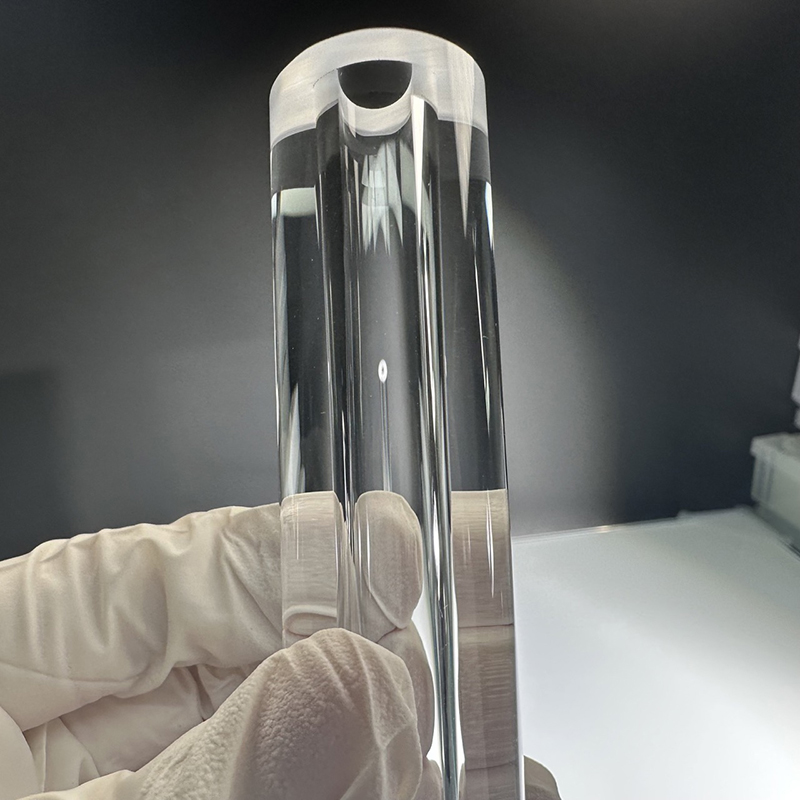

Sapphire cylindrical punching mohato oa ho betla mochini oa CNC mochini o sebetsanang le molamu oa safire

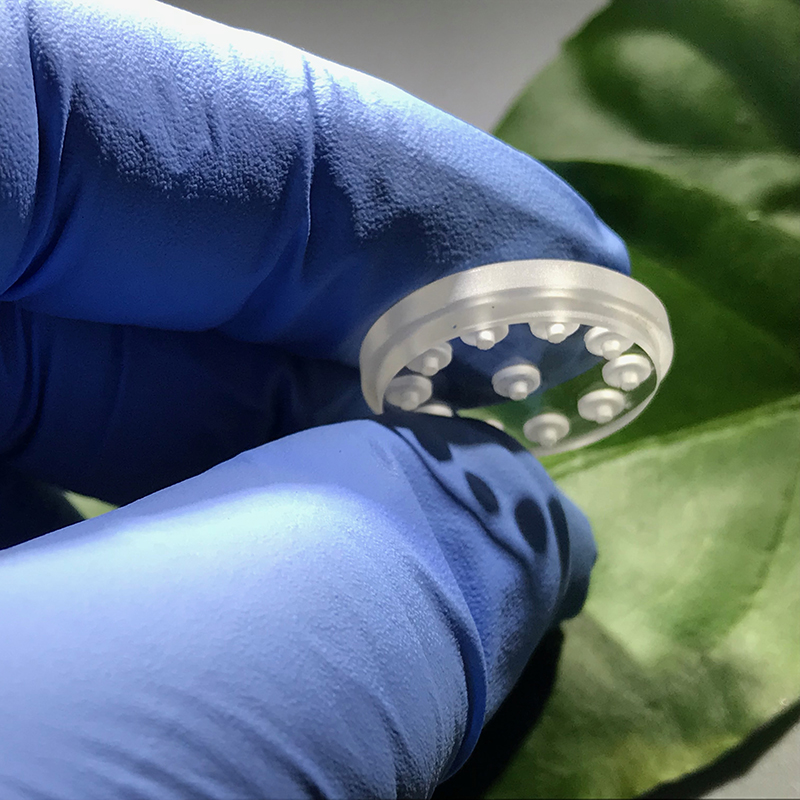

Hlahisa lebokose la wafer

Khampani e shebane le ho itšeha ka mokhoa o nepahetseng, ho ngola, ho otla le ho sebetsana le lisebelisoa tse ling tsa khalase tse kang khalase e tšesaane haholo, khalase ea elektronike, khalase ea pontšo, khalase ea photovoltaic, khalase ea quartz, khalase ea optical joalo-joalo.Khamphani e na le laboratori e hloekileng le workshop ea tlhahiso, sehlopha se nang le boiphihlelo ba nts'etsopele ea thekenoloji le taolo, le lihlopha tse fetang 20 tsa mehloli ea laser e tsoang kantle ho naha, ho kenyeletsoa li-laseser tsa UV, li-ultra-fast lasers, fiber optic lasers, CO2 lasers, joalo-joalo, hammoho le e tšehetsa li-platform tsa ts'ebetso, 'me k'hamphani e boetse e na le lisebelisoa tsa tlhahlobo le tlhahlobo, ho kenyeletsoa microscopes ea 3D, li-interferometer tsa laser, infrared thermography, le likarolo tsa quadratic.

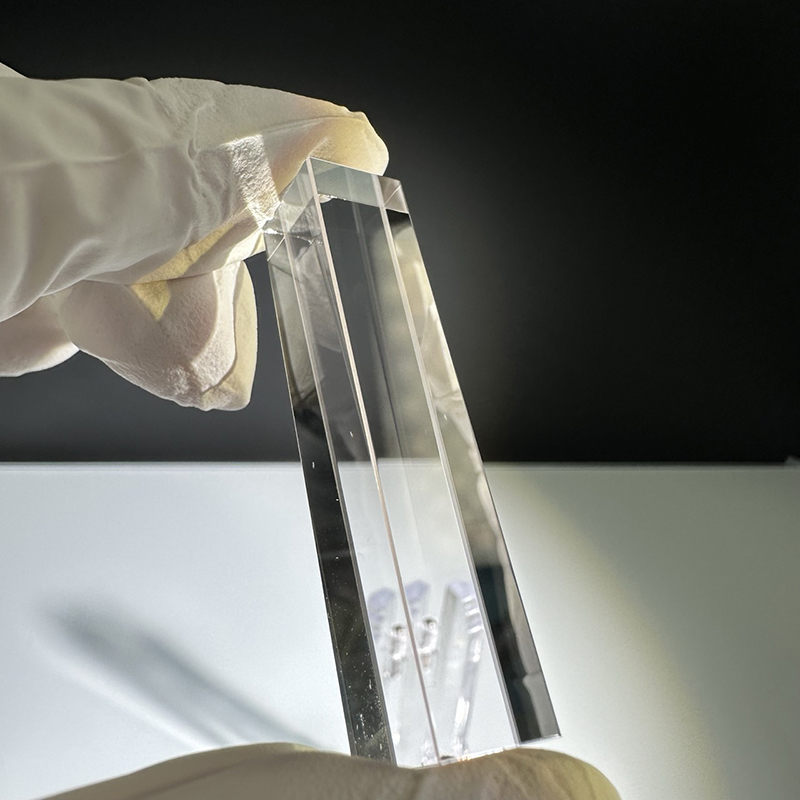

Khampani e thehile sehlopha sa botekgeniki le tsamaiso le barutehi, litsebi tsa naha le indasteri e le mantlha, 'me e hahile laboratori ea kopo ea laser le workshop ea tlhahiso e hloekileng;e boetse e na le lisebelisoa tsa laser processing le mefuta eohle ea lisebelisoa tsa tlhahlobo e nepahetseng.Khampani e itšetlehile ka lipatlisiso le nts'etsopele e ikemetseng, e nang le tsamaiso ea saense, theknoloji, tšebeletso le botumo bo botle e le motheo, e lakatsa ho ba k'hamphani e nang le tlhōlisano e matla ea mantlha.K'hamphani ea laser ea Huanuo e ikemiselitse ho etsa lipatlisiso le nts'etsopele, tlhahiso le thekiso ea lisebelisoa tsa laser ea fiber le laser.Khampani e hlahisa lisebelisoa tsa laser processing, e sebelisoa haholo ka khalase e tšesaane haholo, khalase ea elektroniki, khalase ea pontšo, le lisebelisoa tse ling tse senyang tse kang ho cheka ka mokhoa o nepahetseng le ho itšeha.5 ka har'a mefuta e sa tšoaneng ea khalase kapa lisebelisoa tse ling tse bonaletsang , seha se bōpehileng, taper ea ho phunya e ka fetolehang.Ho cheka khalase ka laser ho ka etsoa ho latela litlhoko, re amohelehile ho re letsetsa bakeng sa keletso!

Sekhahla sa skrine sa mohala oa mohala oa Sapphire, ts'ebetso ea substrate ea safire, mohala oa thelefono oa ho cheka konopo ea lapeng, silicon carbide wafer cut, ho seha lense ea khamera, ho phunya liphanele le ho itšeha, ts'ebetso ea sekoaelo sa sekoaelo le ho cheka ka nepo le ho seha ka sebopeho se ikhethileng.

Setšoantšo se qaqileng