Likristale tse le 'ngoe ha li fumanehe ka tlhaho, 'me le ha li etsahala, hangata li nyenyane haholo-hangata ka sekala sa millimeter (mm)' me ho thata ho li fumana. Litaemane tse tlalehiloeng, li-emerald, li-agate, joalo-joalo, ka kakaretso ha li kenelle ho potoloha 'marakeng, ho sa bue letho ka likopo tsa indasteri; boholo ba tsona li bontšoa limusiamong bakeng sa pontšo. Leha ho le joalo, likristale tse ling li na le boleng ba bohlokoa ba indasteri, joalo ka silicon e le 'ngoe indastering ea potoloho e kopaneng, safire e sebelisoang hangata lilenseng tsa optical, le silicon carbide, e ntseng e eketseha ka matla ho li-semiconductors tsa moloko oa boraro. Bokhoni ba ho hlahisa likristale tsena ka bongata indastering ha bo emele matla a theknoloji ea indasteri le ea mahlale feela empa hape ke letšoao la leruo. Ntho e ka sehloohong e hlokahalang bakeng sa tlhahiso ea kristale e le 'ngoe indastering ke boholo bo boholo, kaha sena ke senotlolo sa ho fokotsa litšenyehelo ka katleho. Ka tlase ho na le likristale tse le 'ngoe tse atisang ho kopana le tsona' marakeng:

1. Sapphire Single Crystal

Sapphire single crystal e bua ka α-Al₂O₃, e nang le tsamaiso ea kristale ea hexagonal, boima ba Mohs ba 9, le lisebelisoa tse tsitsitseng tsa lik'hemik'hale. Ha e qhibilihe ka har'a lino tse nang le asiti kapa alkaline tse senyang, tse hananang le mocheso o phahameng, 'me e bonts'a phetiso e ntle ea khanya, conductivity ea mocheso, le ho kenya motlakase.

Haeba Al ions ka kristale e nkeloa sebaka ke Ti le Fe ion, kristale e bonahala e le putsoa 'me e bitsoa safire. Haeba e nkeloa sebaka ke Cr ions, e bonahala e khubelu 'me e bitsoa ruby. Leha ho le joalo, safire ea indasteri e hloekile α-Al₂O₃, ha e na 'mala ebile e pepenene, ha e na litšila.

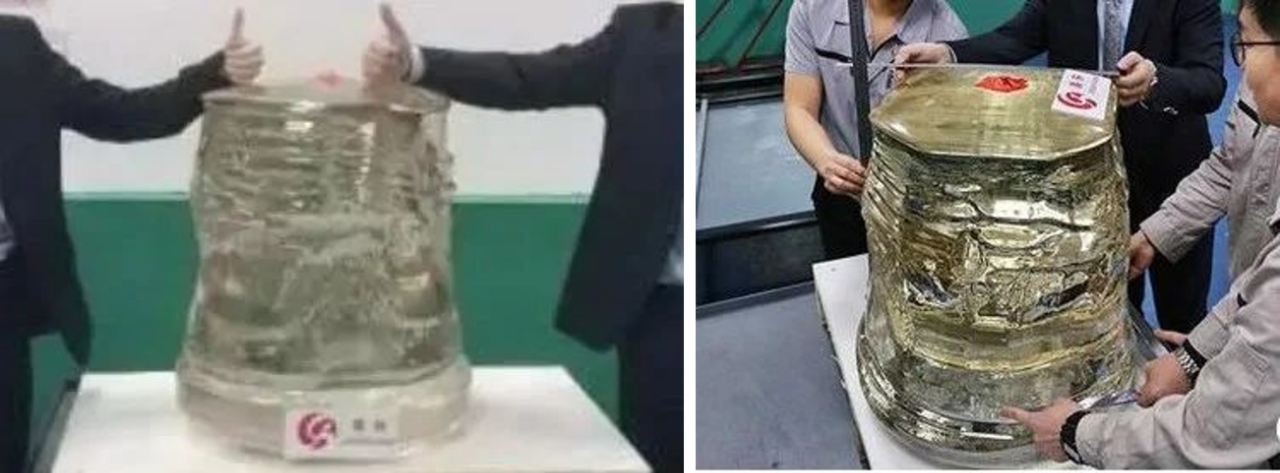

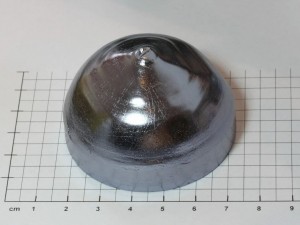

Sapphire ea indasteri hangata e nka sebopeho sa liphaephe, tse botenya ba 400-700 μm le bophara ba lisenthimithara tse 4-8. Tsena li tsejoa e le li-wafers 'me li khaotsoe ho tloha ho li-ingots tsa kristale. Ka tlase ho bontšitsoe engot e sa tsoa huloa ho tsoa seboping se le seng sa kristale, e e-so bentšitsoe kapa ho sehoa.

Ka selemo sa 2018, Khamphani ea elektroniki ea Jinghui e Inner Mongolia e atlehile ho holisa kristale e kholo ka ho fetisisa lefatšeng ea 450 kg ea sapphire e boholo bo boholo. Kristale e kholo ka ho fetisisa ea safire lefatšeng ka bophara e ne e le kristale ea 350 kg e hlahisitsoeng Russia. Joalokaha ho bonoa setšoantšong, kristale ena e na le sebōpeho se tloaelehileng, e hlakileng ka ho feletseng, ha e na mapetso le meeli ea lijo-thollo, 'me e na le li-bubble tse seng kae.

2. Silicon ea Crystal e le 'ngoe

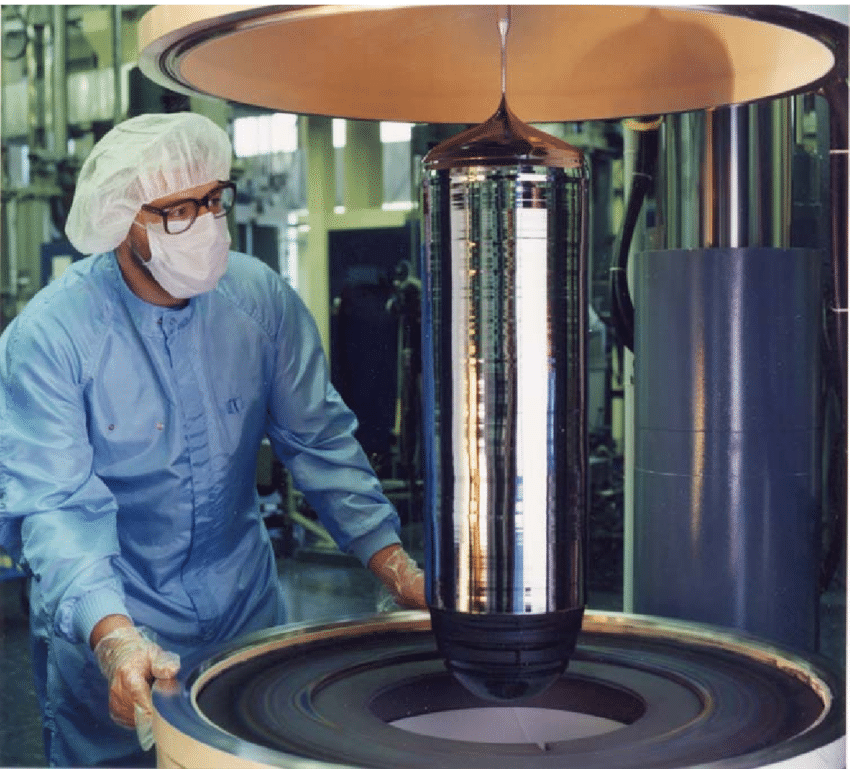

Hajoale, silicon e le 'ngoe ea kristale e sebelisoang bakeng sa li-chips tsa potoloho e kopantsoeng e na le bohloeki ba 99.9999999% ho isa ho 99.999999999% (9-11 nines), le ingot ea silicon ea 420 kg e tlameha ho boloka sebopeho se phethahetseng se kang taemane. Ka tlhaho, esita le daemane e le 'ngoe (200 mg) ha e fumanehe ka seoelo.

Tlhahiso ea lefats'e ea li-ingots tsa silicon e le 'ngoe ea kristale e laoloa ke lik'hamphani tse hlano tse kholo: Shin-Etsu ea Japane (28.0%), SUMCO ea Japane (21.9%), GlobalWafers ea Taiwan (15.1%), SK Siltron ea Korea Boroa (11.6%), le Siltronic ea Jeremane (11.3%). Le moetsi e moholo ka ho fetisisa oa semiconductor wafer naheng ea China, NSIG, e na le karolo ea 2.3% feela ea karolo ea mmaraka. Leha ho le joalo, joaloka mocha, bokhoni ba eona ha boa lokela ho nkoa habobebe. Ka 2024, NSIG e rera ho tsetela morerong oa ho ntlafatsa tlhahiso ea silicon wafer ea 300 mm bakeng sa lipotoloho tse kopaneng, ka chelete e hakanyetsoang ea ¥ 13.2 bilione.

Joalo ka lisebelisoa tse tala tsa lichifi, li-ingots tsa silicon e le 'ngoe ea kristale e hloekileng li ntse li fetoha ho tloha ho 6-inch ho isa ho 12-inch. Lits'oants'o tse etelletseng pele tsa machaba tsa chip, joalo ka TSMC le GlobalFoundries, li ntse li etsa li-chips ho tsoa ho li-silicone wafers tse 12-inch 'marakeng, ha li-wafers tse 8-inch li ntse li felisoa butle butle. Moetapele oa lehae SMIC o ntse a sebelisa li-wafers tse 6-inch. Hajoale, ke SUMCO ea Japane feela e ka hlahisang li-wafer substrates tse 12-inch tse hloekileng haholo.

3. Gallium Arsenide

Li-wafers tsa Gallium arsenide (GaAs) ke lisebelisoa tsa bohlokoa tsa semiconductor, 'me boholo ba tsona ke parameter ea bohlokoa ts'ebetsong ea ho lokisetsa.

Hajoale, li-wafers tsa GaAs hangata li hlahisoa ka boholo ba lisenthimithara tse 2, lisenthimithara tse 3, lisenthimithara tse 4, lisenthimithara tse 6, lisenthimithara tse 8, le lisenthimithara tse 12. Har'a tsena, li-wafers tse 6-inch ke e 'ngoe ea litlhaloso tse sebelisoang haholo.

Boholo bo boholo ba likristale tse le 'ngoe tse hōlileng ka mokhoa oa Horizontal Bridgman (HB) ka kakaretso ke lisenthimithara tse 3, ha mokhoa oa Liquid-Encapsulated Czochralski (LEC) o ka hlahisa likristale tse le' ngoe ho fihlela ho lisenthimithara tse 12 ka bophara. Leha ho le joalo, khōlo ea LEC e hloka litšenyehelo tse phahameng tsa lisebelisoa 'me e fana ka likristale tse sa ts'oaneng le tse phahameng haholo tsa ho senyeha. Mekhoa ea Vertical Gradient Freeze (VGF) le Vertical Bridgman (VB) hajoale e ka hlahisa kristale e le 'ngoe ho fihla ho lisenthimithara tse 8 ka bophara, e nang le sebopeho se batlang se tšoana le sekhahla se tlase sa dislocation.

Theknoloji ea tlhahiso ea li-wafers tse bentšitsoeng tsa 4-inch le 6-inch semi-insulating GaAs e ipabola haholo ke lik'hamphani tse tharo: Sumitomo Electric Industries ea Japane, Freiberger Compound Materials ea Jeremane, le AXT ea US. Ka 2015, li-substrates tse 6-inch li se li ikarabella ho feta 90% ea karolo ea mmaraka.

Ka selemo sa 2019, 'maraka oa lefatše oa GaAs o ne o busoa ke Freiberger, Sumitomo le Beijing Tongmei, ka likabelo tsa mmaraka tsa 28%, 21% le 13% ka ho latellana. Ho latela likhakanyo ka ho buisana le feme ea Yole, thekiso ea lefats'e ea li-GaAs substrates (e fetoletsoeng ho tse lekanang le 2-inch) e fihletse likotoana tse ka bang limilione tse 20 ka 2019 mme ho lebelletsoe hore e tla feta likotoana tse limilione tse 35 ka 2025. (CAGR) ea 9.67% ho tloha 2019 ho isa 2025.

4. Silicon Carbide Single Crystal

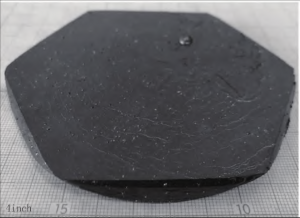

Hajoale, 'maraka o ka ts'ehetsa ka botlalo kholo ea 2-inch le 3-inch bophara ba silicon carbide (SiC) e le 'ngoe ea likristale. Likhamphani tse ngata li tlalehile kholo e atlehileng ea 4-inch 4H-type SiC single crystals, e tšoaeang katleho ea China ea maemo a maemo a lefats'e ho theknoloji ea kholo ea kristale ea SiC. Leha ho le joalo, ho ntse ho e-na le lekhalo le leholo pele ho khoebo.

Ka kakaretso, li-ingots tsa SiC tse hōlileng ka mekhoa ea mokelikeli oa metsi li batla li le nyenyane, tse nang le botenya boemong ba lisenthimithara. Hona hape ke lebaka la litšenyehelo tse phahameng tsa li-wafers tsa SiC.

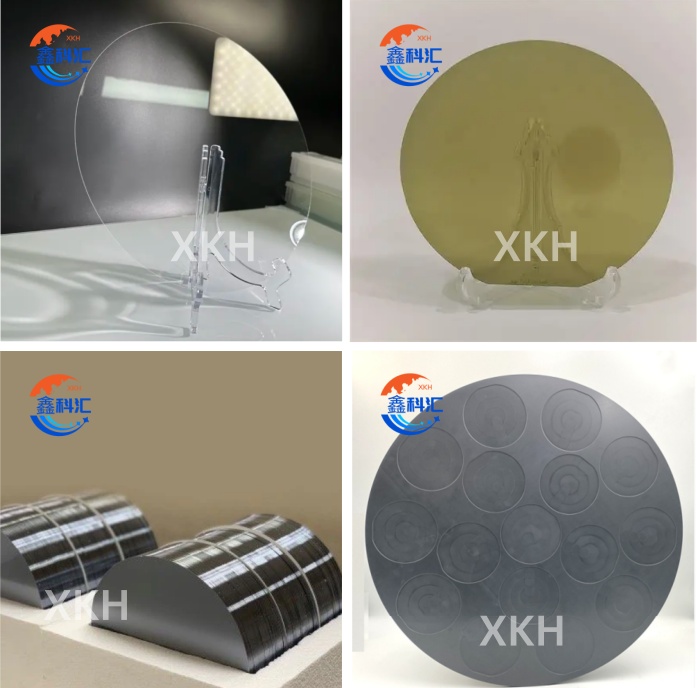

XKH e sebetsa ka thata ho R&D le ts'ebetso e ikhethileng ea lisebelisoa tsa mantlha tsa semiconductor, ho kenyeletsoa safire, silicon carbide (SiC), li-wafers tsa silicon, le li-ceramics, tse koahelang ketane ea boleng bo felletseng ho tloha kholong ea kristale ho isa ho machining a nepahetseng. Re fana ka liphaephe tsa safire tse sebetsang hantle haholo, li-silicon carbide substrates, le li-wafers tsa silicon tse phahameng ka ho fetesisa, tse tšehetsoeng ke litharollo tse lokiselitsoeng joalo ka ho itšeha ka mokhoa o ikhethileng, ho roala holim'a metsi le boqapi bo rarahaneng ba geometry, ho fihlela litlhoko tse feteletseng tsa tikoloho lits'ebetsong tsa laser, tlhahiso ea semiconductor le ts'ebeliso ea matla e nchafalitsoeng.

Ho latela litekanyetso tsa boleng, lihlahisoa tsa rona li na le ho nepahala ha boemo ba micron,> 1500 ° C botsitso ba mocheso, le khanyetso e phahameng ea kutu, ho netefatsa ho ts'epahala maemong a thata a ts'ebetso. Ho feta moo, re fana ka li-quartz substrates, lisebelisoa tsa tšepe / tseo e seng tsa tšepe, le likarolo tse ling tsa semiconductor-grade, tse nolofalletsang phetoho e se nang moeli ho tloha ho prototyping ho ea ho tlhahiso ea bongata bakeng sa bareki ho pholletsa le indasteri.

Nako ea poso: Aug-29-2025