P: Ke litheknoloji life tse ka sehloohong tse sebelisoang ho seha le ho lokisa SiC wafer?

A:Silicon carbide (SiC) e na le bothata ba bobeli ho daemane mme e nkuoa e le thepa e thata haholo le e brittle. Ts'ebetso ea ho seha, e kenyelletsang ho seha likristale tse seng li holile ho li etsa liphaephe tse tšesaane, li nka nako ebile li tloaetse ho chesoa. Joalo ka mohato oa pele oa ho kenaSiCts'ebetso ea kristale e le 'ngoe, boleng ba ho seha bo na le tšusumetso e kholo ho sila, ho bentša le ho fokotseha ho latelang. Hangata ho qhekella ho hlahisa mapetsong a holim'a metsi le a ka tlas'a lefatše, ho eketsa litekanyetso tsa ho robeha ha li-wafer le litšenyehelo tsa tlhahiso. Ka hona, ho laola tšenyo ea mapheo a holim'a metsi nakong ea ho qhekella ho bohlokoa ho nts'etsapele tlhahiso ea sesebelisoa sa SiC.

Hona joale e tlalehiloeng mekhoa ea SiC slicing e kenyelletsa ho khaola ka mokhoa o tsitsitseng, ho senya mahala, ho khaola laser, ho fetisa lera (karohano e batang), le slicing ea ho ntša motlakase. Har'a tsena, ho khutlisa likhoele tse ngata tse nang le li-abrasives tse tsitsitseng tsa daemane ke mokhoa o sebelisoang haholo bakeng sa ho lokisa likristale tse le 'ngoe tsa SiC. Leha ho le joalo, ha boholo ba ingot bo fihla ho lisenthimithara tse 8 ho ea holimo, ho sakha ka terata ea setso ho fetoha ho se sebetse ka lebaka la litlhoko tse phahameng tsa lisebelisoa, litšenyehelo le katleho e tlase. Ho na le tlhoko e potlakileng ea litheknoloji tsa ho seha tse theko e tlase, tse tlase, tse sebetsang hantle haholo.

P: Melemo ea ho seha ka laser ho feta ho seha ka lithapo tse ngata tsa setso ke efe?

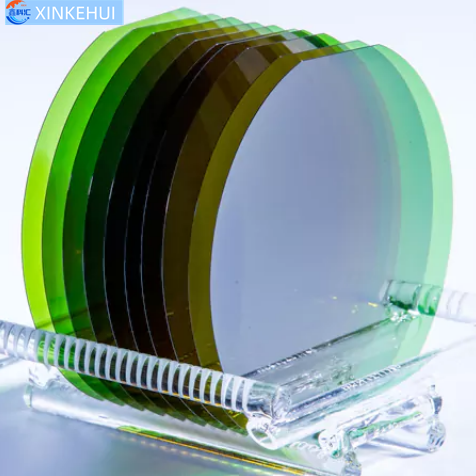

A: Traditional terata sawing seha theSetšoantšo sa SiChammoho le tataiso e itseng ka lilae tse makholo a 'maloa a li-microns tse teteaneng. Lilae li ntan'o siloa ho sebelisoa li-slurries tsa daemane ho tlosa matšoao a sakha le tšenyo e ka tlas'a lefatše, e lateloa ke ho belisoa ha lik'hemik'hale (CMP) ho finyella planarization ea lefats'e, 'me qetellong e hloekisoe ho fumana liphaphatha tsa SiC.

Leha ho le joalo, ka lebaka la boima bo phahameng ba SiC le brittleness, mehato ena e ka baka habonolo ho loana, ho phunyeha, ho eketseha ha litekanyetso tsa ho senya, litšenyehelo tse phahameng tsa tlhahiso, 'me tsa fella ka ho ba le boima bo phahameng le tšilafalo (lerōle, metsi a litšila, joalo-joalo). Ho feta moo, ho sakha ka terata ho lieha ebile ho na le chai e tlase. Likhakanyo li bonts'a hore mokhoa oa khale oa ho seha lithapo tse ngata o fihlella ts'ebeliso ea thepa e ka bang 50% feela, mme ho lahleha ho fihla ho 75% ka mor'a ho bentša le ho sila. Lintlha tsa pele tsa tlhahiso ea kantle ho naha li bonts'itse hore ho ka nka matsatsi a ka bang 273 a tlhahiso e tsoelang pele ea lihora tse 24 ho hlahisa li-wafers tse 10,000 - tse nkang nako haholo.

Ka lapeng, lik'hamphani tse ngata tsa kholo ea kristale ea SiC li tsepamisitse maikutlo ho eketsa matla a sebōpi. Leha ho le joalo, ho e-na le ho atolosa tlhahiso feela, ke habohlokoa haholo ho nahana ka mokhoa oa ho fokotsa tahlehelo-haholo-holo ha lihlahisoa tsa kristale li e-s'o be molemo ka ho fetisisa.

Lisebelisoa tsa laser slicing li ka fokotsa haholo tahlehelo ea thepa le ho ntlafatsa chai. Ka mohlala, ho sebelisa 20 mm e le 'ngoeSetšoantšo sa SiC:Sawing ea terata e ka fana ka liphaephe tse ka bang 30 tsa botenya ba 350 μm. Ho seha ka laser ho ka fana ka liphaephe tse fetang 50. Haeba botenya bo fokotsehile ho fihla ho 200 μm, li-wafers tse fetang 80 li ka hlahisoa ho tsoa ho ingot e le 'ngoe. Matsatsi a 10-15 ka mekhoa e tloaelehileng, e hlokang lisebelisoa tse phahameng le ho kenya litšenyehelo tse phahameng ka katleho e tlaase. Tlas'a maemo ana, melemo ea laser slicing e ea hlaka, e leng se etsang hore e be thekenoloji e kholo ea bokamoso bakeng sa li-wafers tse 8-inch.

Ka ho itšeha ka laser, nako ea ho seha ka sekoahelo sa 8-inch e ka ba ka tlase ho metsotso e 20, ka tahlehelo ea thepa ka tlase ho 60 μm.

Ka kakaretso, ha ho bapisoa le ho seha ka lithapo tse ngata, laser slicing e fana ka lebelo le holimo, chai e ntle, tahlehelo e tlase ea thepa le ts'ebetso e hloekileng.

P: Liqholotso tsa mantlha tsa tekheniki ho SiC laser slicing ke life?

A: Ts'ebetso ea laser slicing e kenyelletsa mehato e 'meli ea mantlha: phetoho ea laser le karohano ea liphaphatha.

Moko-taba oa phetoho ea laser ke sebopeho sa mabala le ho ntlafatsa paramente. Liparamente tse joalo ka matla a laser, bophara ba sebaka, le lebelo la ho skena kaofela li ama boleng ba phallo ea thepa le katleho ea karohano e latelang ea liphaephe. Geometry ea sebaka se fetotsoeng e etsa qeto ea hore na ho na le boima ba bokaholimo le bothata ba karohano. Bokhopo bo phahameng bo thatafatsa ho sila hamorao le ho eketsa tahlehelo ea thepa.

Kamora ho fetoloa, karohano ea li-wafer hangata e finyelloa ka matla a ho kuta, joalo ka ho robeha ha serame kapa khatello ea maikutlo. Litsamaiso tse ling tsa malapeng li sebelisa li-transducers tsa ultrasonic ho etsa hore ho thothomele bakeng sa karohano, empa sena se ka baka litšitiso le ho senya, ho theola chai ea ho qetela.

Le hoja mehato ena e 'meli e se thata ka tlhaho, ho se lumellane ha boleng ba kristale-ka lebaka la mekhoa e fapaneng ea ho hōla, maemo a doping, le ho aroloa ha khatello ea kelello ka hare-ho ama haholo bothata ba slicing, chai le tahlehelo ea thepa. Ho tseba feela libaka tsa mathata le ho lokisa libaka tsa laser scanning ho ka 'na ha se ntlafatse liphetho haholo.

Ntho ea bohlokoa bakeng sa ho amohela bana ba bangata ke ho nts'etsapele mekhoa le lisebelisoa tse ncha tse ka ikamahanyang le mefuta e mengata ea kristale ho tsoa ho bahlahisi ba fapaneng, ho ntlafatsa maemo a ts'ebetso, le ho aha litsamaiso tsa laser slicing tse sebetsang hohle.

P: Na theknoloji ea laser slicing e ka sebelisoa ho lisebelisoa tse ling tsa semiconductor ntle le SiC?

A: Theknoloji ea ho itšeha ea laser esale e sebelisoa ho mefuta e mengata ea lisebelisoa. Ho li-semiconductors, qalong e ne e sebelisoa bakeng sa ho qoelisa ka liphaephe 'me esale e atolosoa ho seha likristale tse ngata tse ngata tse le 'ngoe.

Ka ntle ho SiC, laser slicing e ka boela ea sebelisoa bakeng sa lisebelisoa tse ling tse thata kapa tse brittle tse kang daemane, gallium nitride (GaN), le gallium oxide (Ga₂O₃). Lithuto tsa pele mabapi le lisebelisoa tsena li bonts'itse monyetla le melemo ea ho seha laser bakeng sa lits'ebetso tsa semiconductor.

P: Na hajoale ho na le lihlahisoa tsa lisebelisoa tsa laser tse seng li hōlile tsa malapeng? Lipatlisiso tsa hau li boemong bofe?

A: Thepa e kholo ea bophara ba SiC laser slicing e nkoa e le lisebelisoa tsa mantlha bakeng sa bokamoso ba tlhahiso ea li-wafer tsa 8-inch SiC. Hona joale, ke Japane feela e ka fanang ka litsamaiso tse joalo, 'me li theko e boima ebile li tlas'a lithibelo tsa ho romela thepa.

Tlhokahalo ea lapeng ea lisebelisoa tsa laser slicing/thinning e hakanngoa hore e ka ba li-unit tse ka bang 1,000, ho ipapisitsoe le merero ea tlhahiso ea SiC le bokhoni bo teng ba terata. Lik'hamphani tse kholo tsa lehae li tsetelitse haholo nts'etsopele, empa ha ho lisebelisoa tsa lapeng tse seng li holile, tse fumanehang khoebong tse seng li fihlile tšebetsong ea indasteri.

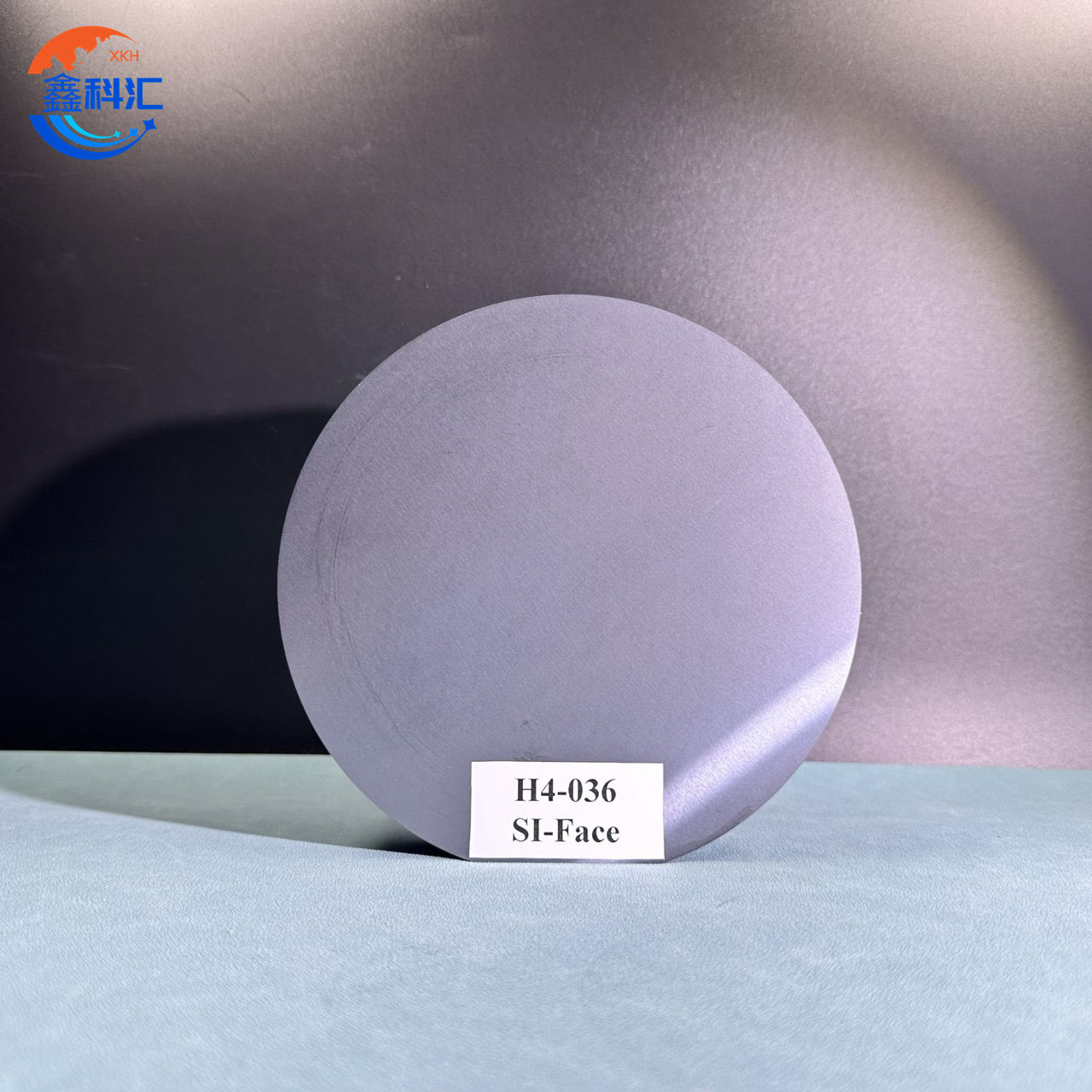

Lihlopha tsa lipatlisiso esale li nts'etsapele theknoloji ea ho phahamisa laser ho tloha ka 2001 'me joale e atoloselitse sena ho seha le ho seha ka laser ea SiC ka bophara bo boholo. Ba thehile mokhoa oa prototype le mekhoa ea ho seha e khonang ho:Ho seha le ho fokotsa 4-6 inch semi-insulating SiC wafersSlicing 6–8 inch conductive SiC ingotsMaemo a ts'ebetso:6–8 inch semi-insulating SiC: nako ea ho slicing 10–15 metsotso/sephaphatha; tahlehelo ea thepa <30 μm6-8 inch conductive SiC: nako ea slicing 14-20 metsotso / sephaphatha; tahlehelo ea thepa <60 μm

Ho hakanngoa hore kotulo ea liphaephe e eketsehile ka 50%

Ka mor'a ho khaola, li-wafers li finyella litekanyetso tsa naha tsa geometry ka mor'a ho sila le ho bentša. Boithuto bo boetse bo bonts'a hore litlamorao tsa mocheso tse susumetsoang ke laser ha li ame haholo khatello ea maikutlo kapa jiometry ka har'a li-wafers.

Thepa e tšoanang e boetse e sebelisitsoe ho netefatsa bokhoni ba ho seha taemane, GaN, le likristale tse le 'ngoe tsa Ga₂O₃.

Nako ea poso: May-23-2025