Litaba tsa indasteri

-

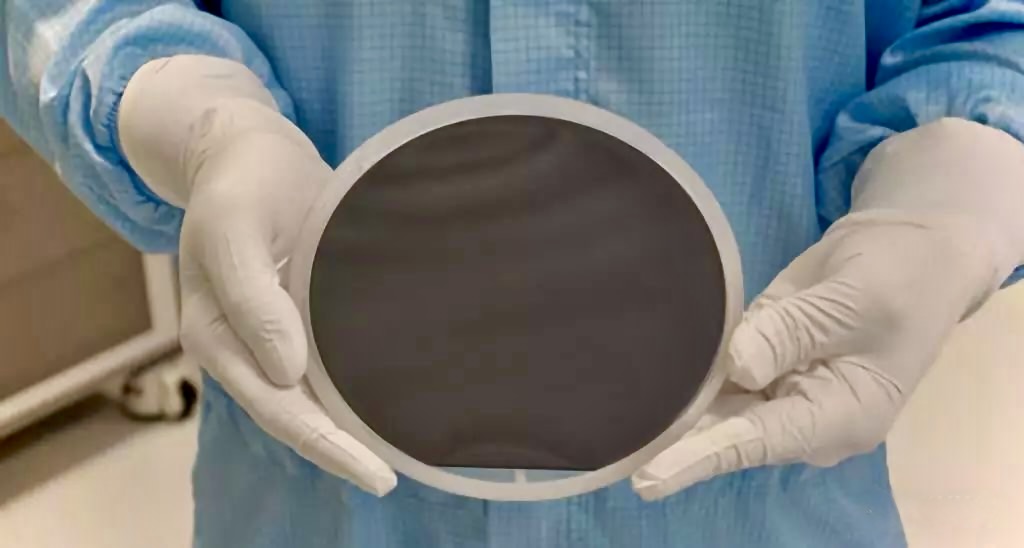

Litharollo tse tsoetseng pele tsa ho paka bakeng sa li-wafers tsa semiconductor: Seo u hlokang ho se tseba

Lefatšeng la li-semiconductors, li-wafers hangata li bitsoa "pelo" ea lisebelisoa tsa elektronike. Empa pelo e le 'ngoe ha e etse ntho e phelang—ho e sireletsa, ho etsa bonnete ba hore e sebetsa hantle, le ho e hokahanya ka mokhoa o sa tsitsang le lefatše le ka ntle ho hloka tharollo e tsoetseng pele ea ho e paka. Ha re hlahlobeng lintho tse khahlang...Bala haholoanyane -

Ho notlolla Liphiri tsa ho Fumana Mofani ea Tšepahalang oa Silicon Wafer

Ho tloha ho smartphone e ka pokothong ea hau ho ea ho li-sensor tsa likoloi tse ikemetseng, li-wafers tsa silicon li theha mokokotlo oa theknoloji ea sejoale-joale. Ho sa tsotellehe ho ba teng hohle ha bona, ho fumana morekisi ea tšepahalang oa likarolo tsena tsa bohlokoa ho ka ba thata ka mokhoa o makatsang. Sengoliloeng sena se fana ka pono e ncha mabapi le senotlolo ...Bala haholoanyane -

Glass e Fetoha Sethala se Secha sa Packaging

Khalase e fetoha lisebelisoa tsa sethala ka potlako bakeng sa limmaraka tsa terminal tse etelletsoeng pele ke litsi tsa data le likhokahano tsa mehala. Ka har'a litsi tsa data, e ts'ehetsa bajari ba liphutheloana tse peli tsa bohlokoa: meralo ea chip le tlhahiso ea optical/output (I/O). Coefficient ea eona e tlase ea keketseho ea mocheso (CTE) le mahlaseli a tebileng a ultraviolet (DUV ...Bala haholoanyane -

Chiplet e fetotse li-chips

Ka 1965, mothehi-'moho le Intel Gordon Moore o ile a hlalosa se ileng sa fetoha "Molao oa Moore." Ka lilemo tse fetang halofo ea lekholo e tšehelitse phaello e tsitsitseng ea ts'ebetso e kopantsoeng ea potoloho (IC) le ho theoha ha litšenyehelo - motheo oa theknoloji ea morao-rao ea digital. Ka bokhutšoanyane: palo ea li-transistors ho chip e batla e imena habeli ...Bala haholoanyane -

Lisebelisoa tsa bohlokoa tsa Raw bakeng sa Tlhahiso ea Semiconductor: Mefuta ea Li-Wafer Substrates

Li-Wafer Substrates e le Lisebelisoa tsa Bohlokoa ho Semiconductor Devices Wafer substrates ke bajari ba 'mele ba lisebelisoa tsa semiconductor, mme thepa ea bona ea thepa e supa ka kotloloho ts'ebetso ea sesebelisoa, litšenyehelo, le likarolo tsa ts'ebeliso. Ka tlase ke mefuta ea mantlha ea li-wafer substrates hammoho le advantag ea tsona ...Bala haholoanyane -

Qetello ea Mehla? Wolfspeed Bankruptcy e fetola Sebopeho sa SiC

Lipontšo tsa Wolfspeed Bankruptcy Point e kholo ea Phetoho bakeng sa Indasteri ea SiC Semiconductor Wolfspeed, moetapele oa nako e telele oa theknoloji ea silicon carbide (SiC), o kentse kopo ea ho putlama bekeng ena, a tšoaea phetoho e kholo tikolohong ea lefatše ea SiC semiconductor. Khamphani...Bala haholoanyane -

Kakaretso e Felletseng ea Mekhoa e Menyane ea ho Deposition Film: MOCVD, Magnetron Sputtering, le PECVD

Tlhahisong ea semiconductor, athe photolithography le etching e le lits'ebetso tse buuoang khafetsa, mekhoa ea ho beha lifilimi ka epitaxial kapa e tšesaane le eona e bohlokoa. Sengoliloeng sena se hlahisa mekhoa e 'maloa e tloaelehileng ea ho beha lifilimi tse tšesaane tse sebelisoang ha ho etsoa chip, ho kenyeletsoa MOCVD, magnetr ...Bala haholoanyane -

Li-Tubes tsa Tšireletso tsa Sapphire Thermocouple: Tsoelo-pele ea Boipheliso ba Mocheso o nepahetseng Tikolohong e thata ea indasteri.

1. Tekanyo ea Mocheso - Mokotla oa Taolo ea Liindasteri Ka liindasteri tsa morao-rao tse sebetsang tlas'a maemo a ntseng a rarahana le a feteletseng, tlhokomelo e nepahetseng le e ka tšeptjoang ea mocheso e fetohile ea bohlokoa. Har'a mahlale a fapaneng a ho utloa, li-thermocouples li amoheloa haholo ka lebaka la ...Bala haholoanyane -

Silicon Carbide e Khantša Likhalase tsa AR, E Bula Liphihlelo tse Ncha tse se nang moeli tse sa lekanyetsoang

Histori ea theknoloji ea batho hangata e ka nkoa e le ho phehella ho sa khaotseng ha “lintlafatso”—lisebelisoa tsa ka ntle tse hōlisang matla a tlhaho. Ka mohlala, mollo o ile oa sebetsa e le mokhoa oa "eketsa-on" oa ho sila lijo, o lokolla matla a mangata bakeng sa khōlo ea boko. Seea-le-moea, se hlahileng bofelong ba lekholo la bo19 la lilemo, ...Bala haholoanyane -

Laser slicing e tla fetoha theknoloji e ka sehloohong ea ho seha 8-inch silicon carbide nakong e tlang. Pokello ea Lipotso le Likarabo

P: Ke litheknoloji life tse ka sehloohong tse sebelisoang ho seha le ho lokisa SiC wafer? A: Silicon carbide (SiC) e na le bothata ba bobeli ba daemane 'me e nkoa e le thepa e thata haholo le e brittle. Ts'ebetso ea ho seha, e kenyelletsang ho seha likristale tse seng li holile ho li etsa liphaephe tse tšesaane, ke ...Bala haholoanyane -

Boemo ba Hona Joale le Mekhoa ea SiC Wafer Processing Technology

E le thepa ea moloko oa boraro ea semiconductor substrate, silicon carbide (SiC) kristale e le 'ngoe e na le tebello e pharaletseng ea ts'ebeliso ea tlhahiso ea lisebelisoa tsa elektronike tsa maqhubu a phahameng le a matla a phahameng. Theknoloji ea ts'ebetso ea SiC e bapala karolo ea makhaola-khang tlhahisong ea substrate ea boleng bo holimo ...Bala haholoanyane -

Naleli e ntseng e phahama ea semiconductor ea moloko oa boraro: Gallium nitride lintlha tse 'maloa tse ncha tsa kholo nakong e tlang

Ha ho bapisoa le lisebelisoa tsa silicon carbide, lisebelisoa tsa matla tsa gallium nitride li tla ba le melemo e mengata maemong ao ho ona ho hlokahalang bokhoni, maqhubu, molumo le likarolo tse ling tse felletseng ka nako e le 'ngoe, joalo ka lisebelisoa tse thehiloeng ho gallium nitride li sebelitse ka katleho ...Bala haholoanyane