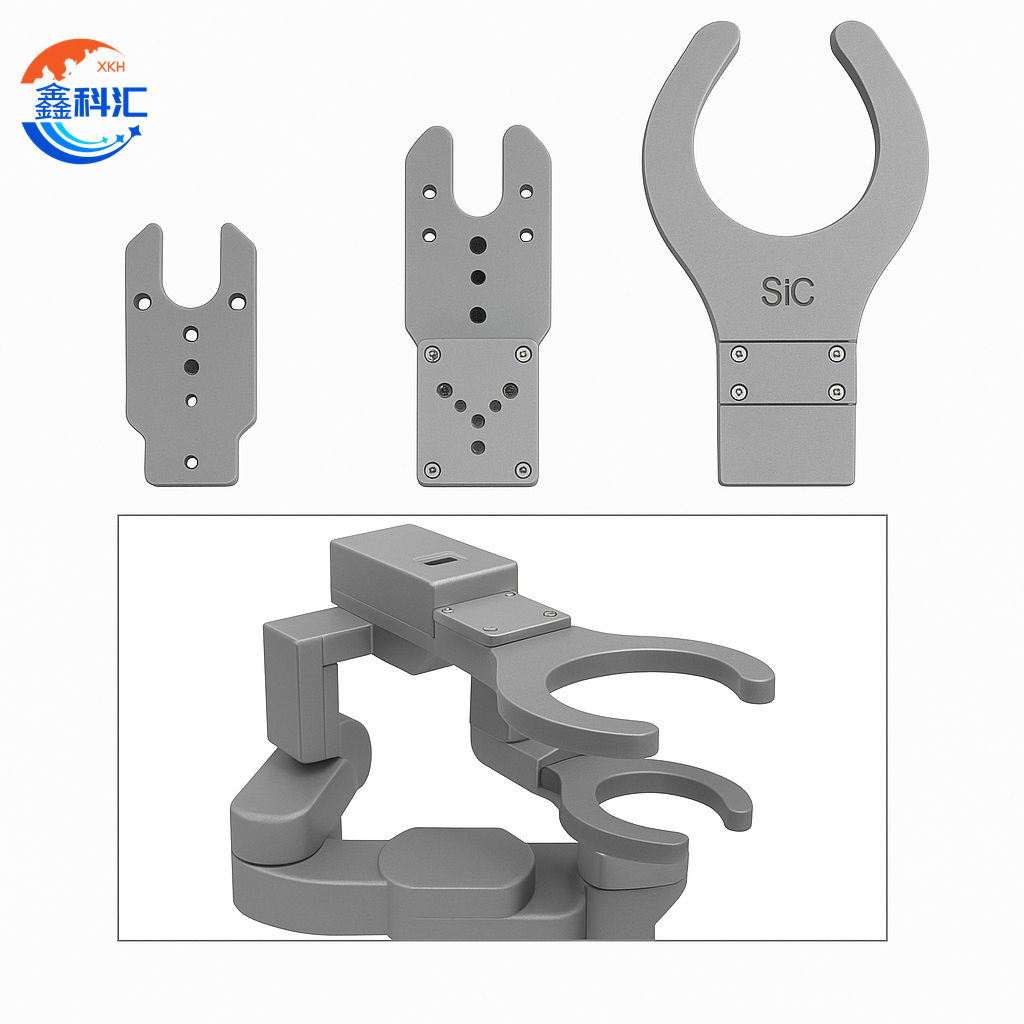

SiC ceramic end effector e fanang ka letsoho bakeng sa ho jara liphaphatha

SiC ceramic end effector Abstract

SiC (Silicon Carbide) sephetho sa ho qetela sa ceramic ke karolo ea bohlokoa lits'ebetsong tsa ho sebetsana le li-wafer tse nepahetseng haholo tse sebelisoang tlhahisong ea semiconductor le tikoloho e tsoetseng pele ea microfabrication. E etselitsoe ho fihlela litlhoko tse hlokahalang tsa tikoloho e hloekileng haholo, e phahameng haholo, le e tsitsitseng haholo, sephetho sena se ikhethileng se netefatsa lipalangoang tse tšepahalang le tse se nang tšilafalo nakong ea mehato ea bohlokoa ea tlhahiso joalo ka lithography, etching le deposition.

Ho sebelisa thepa ea boleng bo holimo ea silicon carbide-joalo ka ts'ebetso e phahameng ea mocheso, boima bo feteletseng, ho se sebetse hantle ha lik'hemik'hale, le katoloso e nyane ea mocheso - SiC ceramic end-effector e fana ka ho satalla ha mochini le botsitso bo sa bapisoang leha e le tlas'a libaesekele tse futhumetseng kapa ka likamoreng tse senyang. Litšobotsi tsa eona tse tlase tsa tlhahiso ea likaroloana le litšoaneleho tsa ho hanyetsa plasma li e etsa hore e tšoanelehe ka ho khetheha bakeng sa lits'ebetso tsa ho hloekisa le ho sebetsa ka vacuum, moo ho boloka botsitso ba bokaholimo le ho fokotsa tšilafalo ea likaroloana ho bohlokoa haholo.

SiC ceramic end effector Application

1. Semiconductor Wafer Handling

Lisebelisoa tsa ho qetela tsa SiC ceramic li sebelisoa haholo indastering ea semiconductor bakeng sa ho sebetsana le li-wafers tsa silicon nakong ea tlhahiso e ikemetseng. Lisebelisoa tsena tsa ho qetela hangata li kentsoe matsohong a liroboto kapa lits'ebetsong tsa phetisetso ea vacuum mme li etselitsoe ho amohela liphaephe tsa boholo bo fapaneng joalo ka 200mm le 300mm. Li bohlokoa lits'ebetsong tse kenyelletsang Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), etching, le diffusion-moo mocheso o phahameng, maemo a vacuum le likhase tse senyang li atileng. Ho hanyetsa mocheso o ikhethang oa SiC le botsitso ba lik'hemik'hale li etsa hore e be thepa e loketseng ho mamella maemo a thata joalo ntle le ho senyeha.

2. Kamore e Hloekileng le Ho lumellana ha Vacuum

Likamoreng tse hloekileng le tsa vacuum, moo tšilafalo ea likaroloana e tlamehang ho fokotsoa, li-ceramics tsa SiC li fana ka melemo e mengata. Sebaka se teteaneng, se boreleli sa thepa ha se khone ho hlahisa likaroloana, se thusa ho boloka botšepehi nakong ea lipalangoang. Sena se etsa hore lihlahisoa tsa ho qetela tsa SiC li tšoanelehe hantle bakeng sa lits'ebetso tse mahlonoko tse kang Extreme Ultraviolet Lithography (EUV) le Atomic Layer Deposition (ALD), moo bohloeki bo leng bohlokoa. Ho feta moo, ts'ebetso e tlase ea SiC le khanyetso e phahameng ea plasma e netefatsa ts'ebetso e ts'eptjoang ka har'a likamore tsa vacuum, e lelefatsa nako ea bophelo ea lisebelisoa le ho fokotsa khafetsa ea tokiso.

3. High-Precision Positioning Systems

Ho nepahala le botsitso li bohlokoa lits'ebetsong tse tsoetseng pele tsa ho sebetsana le li-wafer, haholoholo ho metrology, tlhahlobo le lisebelisoa tsa ho tsamaisana. Li-ceramics tsa SiC li na le coefficient e tlase haholo ea ho atolosoa ha mocheso le ho satalla ho hoholo, tse lumellang sephetho sa ho qetela ho boloka sebopeho sa sona se nepahetseng esita le tlas'a libaesekele tse futhumetseng kapa mojaro oa mochini. Sena se etsa bonnete ba hore li-wafers li lula li hlophisitsoe hantle nakong ea lipalangoang, ho fokotsa kotsi ea li-micro-scratches, ho se lumellane, kapa liphoso tsa ho lekanya - lintlha tse ntseng li le bohlokoa haholo ho li-sub-5nm process node.

SiC ceramic end effector Properties

1. Matla a Phahameng a Mechanical le Thata

Li-ceramics tsa SiC li na le matla a ikhethang a mochini, a nang le matla a feto-fetohang hangata a fetang 400 MPa le boleng ba boima ba Vickers ka holimo ho 2000 HV. Sena se etsa hore li hanane haholo le khatello ea maikutlo, tšusumetso, le ho khathala, le kamora ts'ebeliso ea nako e telele. Ho tiea ho hoholo ha SiC ho boetse ho fokotsa ho kheloha nakong ea phetisetso ea li-wafer tse lebelo le holimo, ho netefatsa boemo bo nepahetseng le bo ka phetoang.

2. E babatsehang Thermal Stability

E 'ngoe ea thepa ea bohlokoa ka ho fetisisa ea li-ceramics tsa SiC ke bokhoni ba tsona ba ho mamella mocheso o phahameng ka ho fetisisa-hangata ho fihlela ho 1600 ° C libakeng tse sa sebetseng - ntle le ho lahleheloa ke botšepehi ba mechine. Coefficient ea bona e tlase ea katoloso ea mocheso (~4.0 x 10⁻⁶ /K) e netefatsa botsitso ba maemo tlas'a libaesekele tse futhumatsang, e leng se etsang hore e be tse loketseng lits'ebetso tse kang CVD, PVD, le annealing ea mocheso o phahameng.

Q&A sephetho sa ho qetela sa SiC ceramic

Q: Ke lintho life tse sebelisoang ho li-wafer end effector?

A:Li-wafer end effecters hangata li entsoe ka thepa e fanang ka matla a phahameng, botsitso ba mocheso, le tlhahiso e tlase ea likaroloana. Har'a tsena, Silicon Carbide (SiC) ceramic ke e 'ngoe ea lisebelisoa tse tsoetseng pele le tse ratoang haholo. Li-ceramics tsa SiC li thata haholo, li tsitsitse mochesong, ha li na lik'hemik'hale, 'me ha li khone ho roala, li etsa hore li tšoanelehe bakeng sa ho tšoara liphaephe tse bonojoana tsa silicon libakeng tse hloekileng le tsa vacuum. Ha ho bapisoa le quartz kapa tšepe e koahetsoeng, SiC e fana ka botsitso bo phahameng ka ho fetisisa tlas'a mocheso o phahameng 'me ha e tšolle likaroloana, tse thusang ho thibela tšilafalo.