4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer bakeng sa MOS kapa SBD

SiC Substrate SiC Epi-wafer Brief

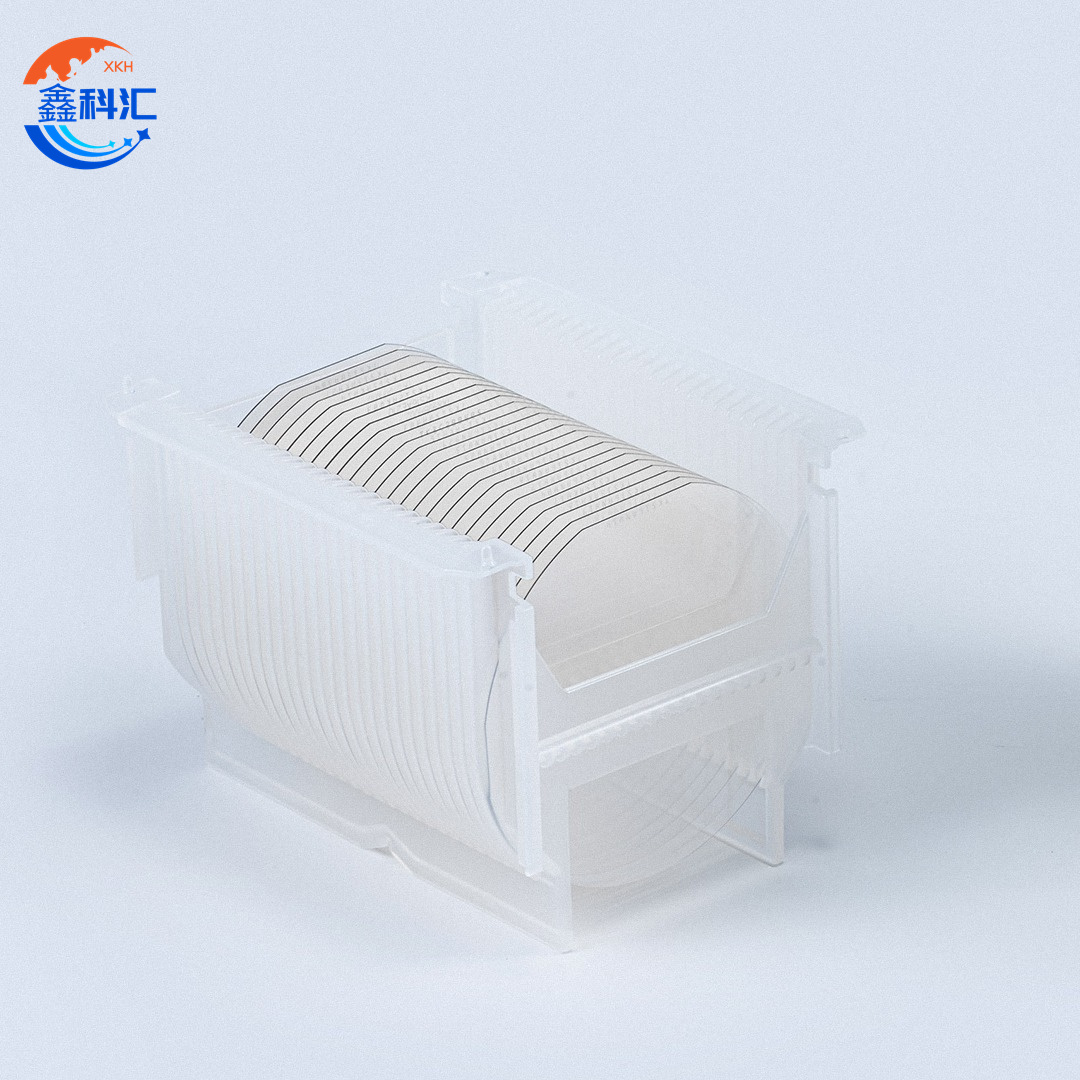

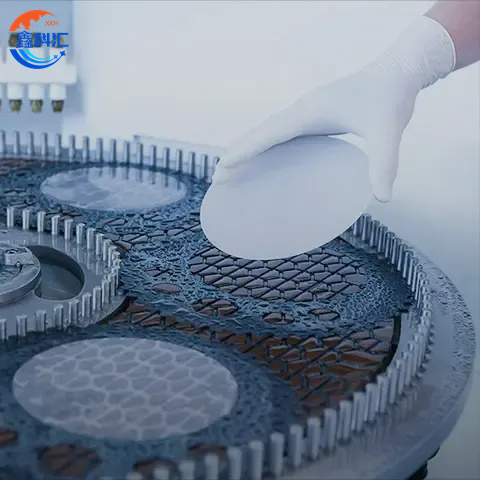

Re fana ka pokello e felletseng ea li-substrates tsa SiC tsa boleng bo holimo le li-wafer tsa sic ka li-polytypes tse ngata le li-doping profiles-ho kenyeletsoa 4H-N (n-type conductive), 4H-P (p-type conductive), 4H-HPSI (high-purity semi-insulating), le 6H-P (p-type conductive) - 4 ″ conductive) ″ 6 ″ kaofela, 6″ ″ 4 ho fihlela ho 12 ″. Ka holim'a li-substrates tse se nang letho, litšebeletso tsa rona tsa kholo ea epi wafer li fana ka li-wafers tsa epitaxial (epi) tse nang le botenya bo laoloang ka thata (1-20 µm), likhahla tsa doping, le ho teteana ha bokooa.

Mohala o mong le o mong oa sic le epi wafer o hlahlojoa ka har'a mohala (micropipe density <0.1 cm⁻², bokaholimo ba Ra <0.2 nm) le sebopeho se felletseng sa motlakase (CV, 'mapa oa resistivity) ho netefatsa ts'ebetso e ts'oanang ea kristale. Ebang e sebelisetsoa li-module tsa motlakase oa motlakase, li-amplifiers tsa RF tse phahameng-frequency, kapa lisebelisoa tsa optoelectronic (LED, photodetectors), substrate ea rona ea SiC le mehala ea sehlahisoa sa epi e fana ka ts'epo, botsitso ba mocheso, le matla a ho senyeha a hlokoang ke lits'ebetso tsa kajeno tse boima haholo.

Mefuta le ts'ebeliso ea SiC Substrate 4H-N

-

4H-N SiC substrate Polytype (Hexagonal) Sebopeho

Wide bandgap ea ~ 3.26 eV e netefatsa ts'ebetso e tsitsitseng ea motlakase le matla a mocheso tlas'a maemo a phahameng a mocheso le a matla a motlakase.

-

SiC substrateDoping ea mofuta oa N

Doping ea naetrojene e laoloang ka nepo e fana ka likhahla ho tloha ho 1×10¹⁶ ho isa ho 1×10¹⁹ cm⁻³ le lisebelisoa tsa elektronike tsa mocheso oa kamore ho fihla ho ~900 cm²/V·s, ho fokotsa tahlehelo ea conduction.

-

SiC substrateWide Resistivity & Uniformity

Botenya bo teng ba 0.01–10 Ω·cm le botenya ba wafer ba 350–650 µm bo nang le ±5% ea ho mamella li-doping le botenya—e loketseng ho etsoa ha lisebelisoa tse matla haholo.

-

SiC substrateTekanyo e tlase ea Sekoli

Boima ba micropipe <0.1 cm⁻² le density ea basal-plane dislocation < 500 cm⁻², ho fana ka > 99% ea tlhahiso ea lisebelisoa le botšepehi bo phahameng ba kristale.

- SiC substrateE ikhethang Thermal Conductivity

Thermal conductivity ho fihla ho ~ 370 W/m·K e thusa ho tlosa mocheso hantle, ho matlafatsa ts'epehi ea sesebelisoa le ho teteka ha matla.

-

SiC substrateLikopo tse reriloeng

Li-SiC MOSFET, li-schottky diode, li-module tsa motlakase le lisebelisoa tsa RF bakeng sa li-drive tsa likoloi tsa motlakase, li-inverters tsa letsatsi, li-drive tsa indasteri, li-traction systems, le limmaraka tse ling tse boima tsa motlakase.

Litlhaloso tsa mofuta oa 6inch 4H-N oa SiC | ||

| Thepa | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Kereiti | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Diameter | 149.5 limilimithara - 150.0 limilimithara | 149.5 limilimithara - 150.0 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Off axis: 4.0° ho leba <1120> ± 0.5° | Off axis: 4.0° ho leba <1120> ± 0.5° |

| Boima ba Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Ho hanyetsa | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Maemo a Motheo a Flat | [10-10] ± 50° | [10-10] ± 50° |

| Bolelele ba Phatlalatso ba Pele | 475 limilimithara ± 2.0 limilimithara | 475 limilimithara ± 2.0 limilimithara |

| Kenyelletso ea Edge | 3 limilimithara | 3 limilimithara |

| LTV/TIV / Bow / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Boqhobane | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Leseli | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm |

| Hex Plates By High Intensity Light | Sebaka sa pokello ≤ 0.05% | Sebaka sa pokello ≤ 0.1% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 3% |

| Likakaretso tsa Carbon tse bonoang | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 5% |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Kakaretso ea bolelele ≤ 1 wafer bophara | |

| Edge Chips Ka Leseli le Matla a Phahameng | Ha e lumelloe ≥ 0.2 mm bophara le botebo | 7 e lumelletsoe, ≤ 1 mm ka 'ngoe |

| Ho kheloha ha Screw Dislocation | <500cm³ | <500cm³ |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | ||

| Sephutheloana | Multi-wafer Cassette Kapa Single Wafer Container | Multi-wafer Cassette Kapa Single Wafer Container |

Litlhaloso tsa mofuta oa 8inch 4H-N oa SiC | ||

| Thepa | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Kereiti | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Diameter | 199.5 limilimithara - 200.0 limilimithara | 199.5 limilimithara - 200.0 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0° ho leba <110> ± 0.5° | 4.0° ho leba <110> ± 0.5° |

| Boima ba Micropipe | ≤ 0.2 cm² | ≤ 5 cm² |

| Ho hanyetsa | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Noble Orientation | ||

| Kenyelletso ea Edge | 3 limilimithara | 3 limilimithara |

| LTV/TIV / Bow / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Boqhobane | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Leseli | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm |

| Hex Plates By High Intensity Light | Sebaka sa pokello ≤ 0.05% | Sebaka sa pokello ≤ 0.1% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 3% |

| Likakaretso tsa Carbon tse bonoang | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 5% |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Kakaretso ea bolelele ≤ 1 wafer bophara | |

| Edge Chips Ka Leseli le Matla a Phahameng | Ha e lumelloe ≥ 0.2 mm bophara le botebo | 7 e lumelletsoe, ≤ 1 mm ka 'ngoe |

| Ho kheloha ha Screw Dislocation | <500cm³ | <500cm³ |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | ||

| Sephutheloana | Multi-wafer Cassette Kapa Single Wafer Container | Multi-wafer Cassette Kapa Single Wafer Container |

4H-SiC ke lisebelisoa tse sebetsang hantle tse sebelisoang bakeng sa lisebelisoa tsa motlakase tsa motlakase, lisebelisoa tsa RF, le lisebelisoa tsa mocheso o phahameng. "4H" e bolela sebopeho sa kristale, se nang le mahlakore a mabeli, 'me "N" e bontša mofuta oa doping o sebelisoang ho ntlafatsa ts'ebetso ea thepa.

The4H-SiCMofuta ona o sebelisoa hangata bakeng sa:

Motlakase oa Motlakase:E sebelisoa ho lisebelisoa tse kang diode, MOSFETs, le IGBTs bakeng sa likoloi tsa motlakase tsa motlakase, mechine ea indasteri, le lisebelisoa tsa matla a tsosolositsoeng.

Theknoloji ea 5G:Ka tlhokahalo ea 5G ea likarolo tse phahameng le tse sebetsang hantle haholo, bokhoni ba SiC ba ho sebetsana le maqhubu a phahameng le ho sebetsa ka mocheso o phahameng o etsa hore e be e loketseng bakeng sa li-amplifiers tsa setsi sa setsi le lisebelisoa tsa RF.

Sistimi ea Matla a Letsatsi:Lisebelisoa tse ntle tsa SiC tsa ho sebetsana le matla li loketse li-inverters le li-converter tsa photovoltaic (matla a letsatsi).

Likoloi tsa Motlakase (EVs):SiC e sebelisoa haholo ho li-powertrains tsa EV bakeng sa phetolo ea matla e sebetsang hantle haholoanyane, tlhahiso e tlase ea mocheso, le matla a phahameng a matla.

Mefuta le ts'ebeliso ea SiC Substrate 4H Semi-Insulating

Thepa:

-

Mekhoa ea ho laola boima ba 'mele ntle le micropipe: E netefatsa ho ba sieo ha li-micropipes, ho ntlafatsa boleng ba substrate.

-

Mekhoa ea ho laola monocrystalline: E netefatsa sebopeho se le seng sa kristale bakeng sa thepa e ntlafalitsoeng ea thepa.

-

Mekhoa ea ho laola li-inclusions: E fokotsa ho ba teng ha litšila kapa li-inclusions, ho netefatsa substrate e hloekileng.

-

Mekhoa ea ho laola ho hanyetsa: E lumella taolo e nepahetseng ea resistivity ea motlakase, e leng ea bohlokoa bakeng sa ts'ebetso ea sesebelisoa.

-

Mekhoa ea ho laola le ho laola litšila: E laola le ho fokotsa ho kenngoa ha litšila ho boloka botšepehi ba substrate.

-

Mekhoa ea ho laola bophara ba mehato ea substrate: E fana ka taolo e nepahetseng holim'a bophara ba mehato, ho netefatsa ho tsitsisa ho pholletsa le substrate

6Inch 4H-semi SiC substrate litlhaloso | ||

| Thepa | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Diameter (mm) | 145 limilimithara - 150 limilimithara | 145 limilimithara - 150 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Ka lehlakoreng le leng: ±0.0001° | Ka lehlakoreng le leng: ±0.05° |

| Boima ba Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Ho hanyetsa (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Maemo a Motheo a Flat | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Bolelele ba Phatlalatso ba Pele | Notch | Notch |

| Kenyelletso ea moeli (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤3 µm | ≤3 µm |

| Boqhobane | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Edge Chips Ka Leseli le Matla a Phahameng | ≤ 20 µm | ≤ 60 µm |

| Lipoleiti Tsa Mocheso Ka Leseli le Matla a Phahameng | Kakaretso ≤ 0.05% | Kakaretso ≤ 3% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Likakaretso tsa Carbon tse Bonahalang ≤ 0.05% | Kakaretso ≤ 3% |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | ≤ 0.05% | Kakaretso ≤ 4% |

| Edge Chips Ka Leseli le Matla a Phahameng (Boholo) | Ha e lumelloe > 02 mm Bophara le Botebo | Ha e lumelloe > 02 mm Bophara le Botebo |

| The Aid Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Sephutheloana | Multi-wafer Cassette kapa Single Wafer Container | Multi-wafer Cassette kapa Single Wafer Container |

Tlhaloso ea 4-Inch 4H-Semi Insulating SiC Substrate

| Paramethara | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

|---|---|---|

| Thepa ea 'Mele | ||

| Diameter | 99.5 limilimithara - 100.0 limilimithara | 99.5 limilimithara - 100.0 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Ka lehlakoreng le leng: <600h> 0.5° | Ka lehlakoreng le leng: <000h> 0.5° |

| Thepa ea Motlakase | ||

| Boima ba Micropipe (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Ho hanyetsa | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Mamello ea Geometri | ||

| Maemo a Motheo a Flat | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Bolelele ba Phatlalatso ba Pele | 52.5 limilimithara ± 2.0 limilimithara | 52.5 limilimithara ± 2.0 limilimithara |

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ± 2.0 limilimithara | 18.0 limilimithara ± 2.0 limilimithara |

| Boemo ba Bobeli ba Flat | 90 ° CW ho tloha Prime flat ± 5.0 ° (Si sefahleho holimo) | 90 ° CW ho tloha Prime flat ± 5.0 ° (Si sefahleho holimo) |

| Kenyelletso ea Edge | 3 limilimithara | 3 limilimithara |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Boleng ba Sefahleho | ||

| Bokhopo ba Bokahohle (Polish Ra) | ≤1 nm | ≤1 nm |

| Bokhopo ba Bokaholimo (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge Cracks (Leseli le Phahameng ka ho Fetisisa) | Ha ea lumelloa | Kakaretso bolelele ≥10 limilimithara, petso e le 'ngoe ≤2 limilimithara |

| Litšitiso tsa Letlapa la Hexagonal | ≤0.05% sebaka sa pokello | ≤0.1% sebaka sa pokello |

| Libaka tsa Kenyelletso ea Polytype | Ha ea lumelloa | ≤1% sebaka sa pokello |

| Likakaretso tsa Carbon tse bonoang | ≤0.05% sebaka sa pokello | ≤1% sebaka sa pokello |

| Silicon Surface Scratches | Ha ea lumelloa | ≤1 wafer bophara bo akaretsang bolelele |

| Li-Chips tsa Edge | Ha e lumelloe (≥0.2 mm bophara/botebo) | ≤5 chips (e 'ngoe le e 'ngoe ≤1 mm) |

| Tšilafalo ea Silicon Surface | Ha ea hlalosoa | Ha ea hlalosoa |

| Sephutheloana | ||

| Sephutheloana | Multi-wafer cassette kapa single-wafer setshelo | Multi-wafer cassette kapa |

Kopo:

TheSiC 4H Semi-Insulating substratesli sebelisoa haholo-holo lisebelisoa tsa elektronike tse matla le tse phahameng, haholo-holo hoSebaka sa RF. Li-substrates tsena li bohlokoa bakeng sa lits'ebetso tse fapaneng ho kenyeletsoamekhoa ea puisano ea microwave, radar e hlophisitsoeng ka mekhahlelo, lelisebelisoa tsa motlakase tse se nang mohala. Ts'ebetso ea bona e phahameng ea mocheso le litšobotsi tse ntle tsa motlakase li li etsa hore e be tse loketseng bakeng sa lits'ebetso tse hlokahalang ho lisebelisoa tsa motlakase tsa motlakase le lits'ebetso tsa puisano.

SiC epi wafer 4H-N mofuta oa thepa le tšebeliso

SiC 4H-N Mofuta oa Epi Wafer Properties le Likopo

Thepa ea SiC 4H-N Mofuta oa Epi Wafer:

Sebopeho sa Lintho:

SiC (Silicon Carbide): E tsebahala ka ho thatafala ho ikhethang, ho tsamaisa mocheso o phahameng, le thepa e ntle ea motlakase, SiC e loketse lisebelisoa tsa elektronike tse sebetsang hantle.

4H-SiC Polytype: Polytype ea 4H-SiC e tsejoa ka katleho ea eona e phahameng le botsitso lits'ebetsong tsa elektronike.

Doping ea mofuta oa N: N-type doping (doped with nitrogen) e fana ka mokhoa o babatsehang oa ho tsamaea ha elektronike, ho etsa hore SiC e tšoanelehe bakeng sa lisebelisoa tse phahameng tsa maqhubu le matla a phahameng.

High Thermal Conductivity:

Li-wafers tsa SiC li na le conductivity e phahameng ea mocheso, hangata ho tloha ho120–200 W/m·K, e ba lumellang ho laola mocheso ka katleho lisebelisoa tse matla tse kang li-transistors le diode.

Wide Bandgap:

Ka lekhalo la3.26 eV, 4H-SiC e ka sebetsa ka li-voltage tse phahameng, maqhubu, le mocheso ha li bapisoa le lisebelisoa tse tloaelehileng tsa silicon, e leng se etsang hore e be se loketseng bakeng sa lisebelisoa tse phahameng, tse sebetsang hantle.

Thepa ea Motlakase:

SiC e phahameng ea elektronike motsamao le conductivity etsa hore ho loketse bakeng samatla a elektronike, e fanang ka lebelo la ho chencha ka potlako le matla a ho sebetsana le matla a holimo le a motlakase, e leng se hlahisang mekhoa e metle ea tsamaiso ea matla.

Ho hanyetsa Mechini le Lik'hemik'hale:

SiC ke e 'ngoe ea lisebelisoa tse thata ka ho fetisisa, ea bobeli ho daemane,' me e hanyetsana haholo le oxidation le corrosion, e etsang hore e tšoarelle libakeng tse thata.

Lisebelisoa tsa SiC 4H-N Mofuta oa Epi Wafer:

Motlakase oa Motlakase:

Li-wafers tsa mofuta oa SiC 4H-N li sebelisoa haholo homatla a MOSFET, Li-IGBTs, lediodebakeng saphetoho ea matlalitsamaisong tse kangli-inverters tsa letsatsi, likoloi tsa motlakase, lemekhoa ea ho boloka matla, e fanang ka ts'ebetso e ntlafalitsoeng le ts'ebeliso ea matla.

Likoloi tsa Motlakase (EVs):

In likoloi tsa motlakase tsa motlakase, balaoli ba makoloi, lediteishene tsa ho tjhaja, Li-wafer tsa SiC li thusa ho finyella katleho e ntle ea betri, ho tjhaja kapele, le ho ntlafatsa ts'ebetso ea matla ka kakaretso ka lebaka la bokhoni ba tsona ba ho sebetsana le matla a phahameng le mocheso.

Sistimi ea Matla a Tsosolositsoeng:

Li-inverters tsa letsatsi: Li-wafers tsa SiC li sebelisoa hotsamaiso ea matla a letsatsibakeng sa ho fetola matla a DC ho tloha ho liphanele tsa letsatsi ho ea ho AC, ho eketsa katleho le ts'ebetso ea sistimi ka kakaretso.

Li-Turbine tsa Moea: Theknoloji ea SiC e sebelisoa homekhoa ea ho laola li-turbine tsa moea, ho ntlafatsa tlhahiso ea matla le katleho ea phetoho.

Sepakapaka le Tšireletso:

Li-wafers tsa SiC li loketse ho sebelisoalisebelisoa tsa elektronike tsa sefofanelelikopo tsa sesole, ho kenyeletsatsamaiso ea radarlelisebelisoa tsa elektronike tsa sathelaete, moo ho hanyetsa mahlaseli a phahameng le botsitso ba mocheso li leng bohlokoa.

Lisebelisoa tsa Mocheso o Phahameng le oa Maqhubu a Phahameng:

Li-wafers tsa SiC li sebetsa hantle hahololisebelisoa tsa elektronike tsa mocheso o phahameng, sebelisoa kadienjini tsa sefofane, sepakapaka, lemekhoa ea ho futhumatsa ea indasteri, ha ba ntse ba boloka ts'ebetso maemong a mocheso o feteletseng. Ho feta moo, bandgap ea bona e pharaletseng e lumella ho sebelisoalisebelisoa tse phahameng tsa maqhubujoalo kaLisebelisoa tsa RFlepuisano ka microwave.

| Tlhaloso ea 6-inch N-epit axial | |||

| Paramethara | unit | Z-MOS | |

| Mofuta | Condutivity / Dopant | - | Mofuta oa N / Naetrojene |

| Lera la Buffer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| Lera la 1 la Epi | Epi Layer Thickness | um | 11.5 |

| Epi Layer Thickness Uniformity | % | ±4% | |

| Epi Layers Thickness Tolerance((Spec- Max , Min)/Spec) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1E 15~1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /bolela) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Sebopeho sa Epitaixal Wafer | Inamela | um | ≤±20 |

| TLHOKOMELO | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Litšobotsi tse akaretsang | Bolelele ba mengwapo | mm | ≤30 limilimithara |

| Li-Chips tsa Edge | - | HA HO MOTHO | |

| Tlhaloso ea liphoso | ≥97% (E lekantsoe le 2*2, Litšitiso tse bolaeang li kenyelletsa: Litšitiso li kenyelletsa Moekorope/Makoti a maholo, Sehoete, kgutlotharo | ||

| Tšilafalo ea tšepe | liathomo/cm² | d fll ke ≤5E10 liathomo/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Sephutheloana | Litlhaloso tsa ho paka | li-pcs/lebokose | khasete e nang le liphaphatha tse ngata kapa setshelo se le seng sa sephaphatha |

| 8-inch N-mofuta oa epitaxial | |||

| Paramethara | unit | Z-MOS | |

| Mofuta | Condutivity / Dopant | - | Mofuta oa N / Naetrojene |

| Buffer layer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| Lera la 1 la Epi | Karolelano ea Botenya ba Epi Layers | um | 8 ~ 12 |

| Epi Layers Thickness Uniformity (σ/mean) | % | ≤2.0 | |

| Epi Layers Thickness Tolerance((Spec -Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/mean) | % | ≤5 | |

| Epi Layers Net DopingTolerance((Spec -Max, | % | ± 10.0 | |

| Sebopeho sa Epitaixal Wafer | Mi)/S) Warp | um | ≤50.0 |

| Inamela | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Kakaretso Litšobotsi | Mengwapo | - | Cumulative length≤ 1/2 Wafer bophara |

| Li-Chips tsa Edge | - | ≤2 chips, Radius e 'ngoe le e' ngoe≤1.5mm | |

| Surface Metals Tšilafalo | liathomo/cm2 | ≤5E10 liathomo/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Tlhahlobo ea Sekoli | % | ≥ 96.0 (Mefokolo ea 2X2 e kenyelletsa Micropipe / likoti tse kholo, Lihoete, litšitiso tse tharo, Linear/IGSF-s, BPD) | |

| Surface Metals Tšilafalo | liathomo/cm2 | ≤5E10 liathomo/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Sephutheloana | Litlhaloso tsa ho paka | - | khasete e nang le liphaphatha tse ngata kapa setshelo se le seng sa sephaphatha |

Lipotso le likarabo tsa SiC wafer

Q1: Melemo ea bohlokoa ea ho sebelisa li-wafers tsa SiC holim'a li-wafers tsa setso tsa silicon ho lisebelisoa tsa motlakase ke life?

A1:

Li-wafers tsa SiC li fana ka melemo e mengata ea bohlokoa ho feta li-wafers tsa setso tsa silicon (Si) ka lisebelisoa tsa elektroniki, ho kenyelletsa:

Bokhoni bo Phahameng: SiC e na le bandgap e pharaletseng (3.26 eV) ha e bapisoa le silicon (1.1 eV), e lumellang lisebelisoa ho sebetsa ka maqhubu a phahameng, maqhubu le mocheso. Sena se lebisa tahlehelong e tlase ea matla le ts'ebetso e phahameng ho litsamaiso tsa phetolo ea matla.

High Thermal Conductivity: SiC's conductivity thermal conductivity e phahame haholo ho feta ea silicon, e leng ho nolofalletsang mocheso o ntlafetseng oa ho senya matla a matla a matla, e leng ho ntlafatsang botšepehi le bophelo ba lisebelisoa tsa matla.

Motlakase o Phahameng le Ts'ebetso ea Hona Joale: Lisebelisoa tsa SiC li ka sebetsana le maemo a phahameng a motlakase le a hona joale, e leng se etsang hore li tšoanelehe bakeng sa lisebelisoa tse matla tse kang likoloi tsa motlakase, lisebelisoa tsa matla a tsosolositsoeng, le likoloi tsa likoloi tsa indasteri.

Lebelo la ho Fetola ka potlako: Lisebelisoa tsa SiC li na le matla a ho fetola ka potlako, a tlatsetsang ho fokotsa tahlehelo ea matla le boholo ba tsamaiso, e leng se etsang hore e be tse loketseng bakeng sa lisebelisoa tse phahameng tsa maqhubu.

Q2: Ke lits'ebetso life tsa mantlha tsa li-wafers tsa SiC indastering ea likoloi?

A2:

Indastering ea likoloi, li-wafers tsa SiC li sebelisoa haholo ho:

Likoloi tsa Motlakase (EV) Powertrains: Likarolo tse thehiloeng ho SiC tse kangli-inverterslematla a MOSFETntlafatsa bokgoni le tshebetso ya dikoloi tse tsamaisang motlakase ka ho etsa hore lebelo la ho tjhentjha ka potlako le matla a phahameng a matla. Sena se lebisa bophelong bo bolelele ba betri le ts'ebetso e ntle ka kakaretso ea koloi.

Li-charger tse ka Botong: Lisebelisoa tsa SiC li thusa ho ntlafatsa bokhoni ba lisebelisoa tsa ho tjhaja ka boto ka ho nolofalletsa linako tsa ho tjhaja ka potlako le tsamaiso e ntlafetseng ea mocheso, e leng ntho ea bohlokoa bakeng sa li-EV ho tšehetsa liteishene tsa ho tjhaja matla a phahameng.

Sistimi ea Taolo ea Battery (BMS): Theknoloji ea SiC e ntlafatsa katleho eatsamaiso ea betri, e lumellang hore ho be le taolo e betere ea motlakase, ho sebetsana le matla a holimo, le bophelo bo bolelele ba betri.

Lisebelisoa tsa DC-DC: Li-wafers tsa SiC li sebelisoa hoLi-converter tsa DC-DCho fetolela matla a DC a nang le matla a phahameng ho ea ho matla a tlaase a DC ka mokhoa o atlehileng haholoanyane, e leng sa bohlokoa likoloing tsa motlakase ho laola matla a tsoang betri ho ea likarolong tse sa tšoaneng tsa koloi.

Ts'ebetso e phahameng ea SiC ho li-voltage tse phahameng, mocheso o phahameng, le ts'ebetso e phahameng ea ts'ebetso e etsa hore e be ea bohlokoa bakeng sa phetoho ea indasteri ea likoloi ho ea ho motsamao oa motlakase.

Litlhaloso tsa mofuta oa 6inch 4H-N oa SiC | ||

| Thepa | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Kereiti | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Diameter | 149.5 limilimithara - 150.0 limilimithara | 149.5 limilimithara - 150.0 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Off axis: 4.0° ho leba <1120> ± 0.5° | Off axis: 4.0° ho leba <1120> ± 0.5° |

| Boima ba Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Ho hanyetsa | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Maemo a Motheo a Flat | [10-10] ± 50° | [10-10] ± 50° |

| Bolelele ba Phatlalatso ba Pele | 475 limilimithara ± 2.0 limilimithara | 475 limilimithara ± 2.0 limilimithara |

| Kenyelletso ea Edge | 3 limilimithara | 3 limilimithara |

| LTV/TIV / Bow / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Boqhobane | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Leseli | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm |

| Hex Plates By High Intensity Light | Sebaka sa pokello ≤ 0.05% | Sebaka sa pokello ≤ 0.1% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 3% |

| Likakaretso tsa Carbon tse bonoang | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 5% |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Kakaretso ea bolelele ≤ 1 wafer bophara | |

| Edge Chips Ka Leseli le Matla a Phahameng | Ha e lumelloe ≥ 0.2 mm bophara le botebo | 7 e lumelletsoe, ≤ 1 mm ka 'ngoe |

| Ho kheloha ha Screw Dislocation | <500cm³ | <500cm³ |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | ||

| Sephutheloana | Multi-wafer Cassette Kapa Single Wafer Container | Multi-wafer Cassette Kapa Single Wafer Container |

Litlhaloso tsa mofuta oa 8inch 4H-N oa SiC | ||

| Thepa | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Kereiti | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Diameter | 199.5 limilimithara - 200.0 limilimithara | 199.5 limilimithara - 200.0 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0° ho leba <110> ± 0.5° | 4.0° ho leba <110> ± 0.5° |

| Boima ba Micropipe | ≤ 0.2 cm² | ≤ 5 cm² |

| Ho hanyetsa | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Noble Orientation | ||

| Kenyelletso ea Edge | 3 limilimithara | 3 limilimithara |

| LTV/TIV / Bow / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Boqhobane | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Leseli | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm | Bolelele bo akaretsang ≤ 20 mm bolelele bo le bong ≤ 2 mm |

| Hex Plates By High Intensity Light | Sebaka sa pokello ≤ 0.05% | Sebaka sa pokello ≤ 0.1% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 3% |

| Likakaretso tsa Carbon tse bonoang | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 5% |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Kakaretso ea bolelele ≤ 1 wafer bophara | |

| Edge Chips Ka Leseli le Matla a Phahameng | Ha e lumelloe ≥ 0.2 mm bophara le botebo | 7 e lumelletsoe, ≤ 1 mm ka 'ngoe |

| Ho kheloha ha Screw Dislocation | <500cm³ | <500cm³ |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | ||

| Sephutheloana | Multi-wafer Cassette Kapa Single Wafer Container | Multi-wafer Cassette Kapa Single Wafer Container |

6Inch 4H-semi SiC substrate litlhaloso | ||

| Thepa | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

| Diameter (mm) | 145 limilimithara - 150 limilimithara | 145 limilimithara - 150 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Ka lehlakoreng le leng: ±0.0001° | Ka lehlakoreng le leng: ±0.05° |

| Boima ba Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Ho hanyetsa (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Maemo a Motheo a Flat | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Bolelele ba Phatlalatso ba Pele | Notch | Notch |

| Kenyelletso ea moeli (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤3 µm | ≤3 µm |

| Boqhobane | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Edge Chips Ka Leseli le Matla a Phahameng | ≤ 20 µm | ≤ 60 µm |

| Lipoleiti Tsa Mocheso Ka Leseli le Matla a Phahameng | Kakaretso ≤ 0.05% | Kakaretso ≤ 3% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Likakaretso tsa Carbon tse Bonahalang ≤ 0.05% | Kakaretso ≤ 3% |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | ≤ 0.05% | Kakaretso ≤ 4% |

| Edge Chips Ka Leseli le Matla a Phahameng (Boholo) | Ha e lumelloe > 02 mm Bophara le Botebo | Ha e lumelloe > 02 mm Bophara le Botebo |

| The Aid Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Sephutheloana | Multi-wafer Cassette kapa Single Wafer Container | Multi-wafer Cassette kapa Single Wafer Container |

Tlhaloso ea 4-Inch 4H-Semi Insulating SiC Substrate

| Paramethara | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Kereiti ya Dummy (D Grade) |

|---|---|---|

| Thepa ea 'Mele | ||

| Diameter | 99.5 limilimithara - 100.0 limilimithara | 99.5 limilimithara - 100.0 limilimithara |

| Mofuta oa poly | 4H | 4H |

| Botenya | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Ka lehlakoreng le leng: <600h> 0.5° | Ka lehlakoreng le leng: <000h> 0.5° |

| Thepa ea Motlakase | ||

| Boima ba Micropipe (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Ho hanyetsa | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Mamello ea Geometri | ||

| Maemo a Motheo a Flat | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Bolelele ba Phatlalatso ba Pele | 52.5 limilimithara ± 2.0 limilimithara | 52.5 limilimithara ± 2.0 limilimithara |

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ± 2.0 limilimithara | 18.0 limilimithara ± 2.0 limilimithara |

| Boemo ba Bobeli ba Flat | 90 ° CW ho tloha Prime flat ± 5.0 ° (Si sefahleho holimo) | 90 ° CW ho tloha Prime flat ± 5.0 ° (Si sefahleho holimo) |

| Kenyelletso ea Edge | 3 limilimithara | 3 limilimithara |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Boleng ba Sefahleho | ||

| Bokhopo ba Bokahohle (Polish Ra) | ≤1 nm | ≤1 nm |

| Bokhopo ba Bokaholimo (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge Cracks (Leseli le Phahameng ka ho Fetisisa) | Ha ea lumelloa | Kakaretso bolelele ≥10 limilimithara, petso e le 'ngoe ≤2 limilimithara |

| Litšitiso tsa Letlapa la Hexagonal | ≤0.05% sebaka sa pokello | ≤0.1% sebaka sa pokello |

| Libaka tsa Kenyelletso ea Polytype | Ha ea lumelloa | ≤1% sebaka sa pokello |

| Likakaretso tsa Carbon tse bonoang | ≤0.05% sebaka sa pokello | ≤1% sebaka sa pokello |

| Silicon Surface Scratches | Ha ea lumelloa | ≤1 wafer bophara bo akaretsang bolelele |

| Li-Chips tsa Edge | Ha e lumelloe (≥0.2 mm bophara/botebo) | ≤5 chips (e 'ngoe le e 'ngoe ≤1 mm) |

| Tšilafalo ea Silicon Surface | Ha ea hlalosoa | Ha ea hlalosoa |

| Sephutheloana | ||

| Sephutheloana | Multi-wafer cassette kapa single-wafer setshelo | Multi-wafer cassette kapa |

| Tlhaloso ea 6-inch N-epit axial | |||

| Paramethara | unit | Z-MOS | |

| Mofuta | Condutivity / Dopant | - | Mofuta oa N / Naetrojene |

| Lera la Buffer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| Lera la 1 la Epi | Epi Layer Thickness | um | 11.5 |

| Epi Layer Thickness Uniformity | % | ±4% | |

| Epi Layers Thickness Tolerance((Spec- Max , Min)/Spec) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1E 15~1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /bolela) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Sebopeho sa Epitaixal Wafer | Inamela | um | ≤±20 |

| TLHOKOMELO | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Litšobotsi tse akaretsang | Bolelele ba mengwapo | mm | ≤30 limilimithara |

| Li-Chips tsa Edge | - | HA HO MOTHO | |

| Tlhaloso ea liphoso | ≥97% (E lekantsoe le 2*2, Litšitiso tse bolaeang li kenyelletsa: Litšitiso li kenyelletsa Moekorope/Makoti a maholo, Sehoete, kgutlotharo | ||

| Tšilafalo ea tšepe | liathomo/cm² | d fll ke ≤5E10 liathomo/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Sephutheloana | Litlhaloso tsa ho paka | li-pcs/lebokose | khasete e nang le liphaphatha tse ngata kapa setshelo se le seng sa sephaphatha |

| 8-inch N-mofuta oa epitaxial | |||

| Paramethara | unit | Z-MOS | |

| Mofuta | Condutivity / Dopant | - | Mofuta oa N / Naetrojene |

| Buffer layer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| Lera la 1 la Epi | Karolelano ea Botenya ba Epi Layers | um | 8 ~ 12 |

| Epi Layers Thickness Uniformity (σ/mean) | % | ≤2.0 | |

| Epi Layers Thickness Tolerance((Spec -Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/mean) | % | ≤5 | |

| Epi Layers Net DopingTolerance((Spec -Max, | % | ± 10.0 | |

| Sebopeho sa Epitaixal Wafer | Mi)/S) Warp | um | ≤50.0 |

| Inamela | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Kakaretso Litšobotsi | Mengwapo | - | Cumulative length≤ 1/2 Wafer bophara |

| Li-Chips tsa Edge | - | ≤2 chips, Radius e 'ngoe le e' ngoe≤1.5mm | |

| Surface Metals Tšilafalo | liathomo/cm2 | ≤5E10 liathomo/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Tlhahlobo ea Sekoli | % | ≥ 96.0 (Mefokolo ea 2X2 e kenyelletsa Micropipe / likoti tse kholo, Lihoete, litšitiso tse tharo, Linear/IGSF-s, BPD) | |

| Surface Metals Tšilafalo | liathomo/cm2 | ≤5E10 liathomo/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Sephutheloana | Litlhaloso tsa ho paka | - | khasete e nang le liphaphatha tse ngata kapa setshelo se le seng sa sephaphatha |

Q1: Melemo ea bohlokoa ea ho sebelisa li-wafers tsa SiC holim'a li-wafers tsa setso tsa silicon ho lisebelisoa tsa motlakase ke life?

A1:

Li-wafers tsa SiC li fana ka melemo e mengata ea bohlokoa ho feta li-wafers tsa setso tsa silicon (Si) ka lisebelisoa tsa elektroniki, ho kenyelletsa:

Bokhoni bo Phahameng: SiC e na le bandgap e pharaletseng (3.26 eV) ha e bapisoa le silicon (1.1 eV), e lumellang lisebelisoa ho sebetsa ka maqhubu a phahameng, maqhubu le mocheso. Sena se lebisa tahlehelong e tlase ea matla le ts'ebetso e phahameng ho litsamaiso tsa phetolo ea matla.

High Thermal Conductivity: SiC's conductivity thermal conductivity e phahame haholo ho feta ea silicon, e leng ho nolofalletsang mocheso o ntlafetseng oa ho senya matla a matla a matla, e leng ho ntlafatsang botšepehi le bophelo ba lisebelisoa tsa matla.

Motlakase o Phahameng le Ts'ebetso ea Hona Joale: Lisebelisoa tsa SiC li ka sebetsana le maemo a phahameng a motlakase le a hona joale, e leng se etsang hore li tšoanelehe bakeng sa lisebelisoa tse matla tse kang likoloi tsa motlakase, lisebelisoa tsa matla a tsosolositsoeng, le likoloi tsa likoloi tsa indasteri.

Lebelo la ho Fetola ka potlako: Lisebelisoa tsa SiC li na le matla a ho fetola ka potlako, a tlatsetsang ho fokotsa tahlehelo ea matla le boholo ba tsamaiso, e leng se etsang hore e be tse loketseng bakeng sa lisebelisoa tse phahameng tsa maqhubu.

Q2: Ke lits'ebetso life tsa mantlha tsa li-wafers tsa SiC indastering ea likoloi?

A2:

Indastering ea likoloi, li-wafers tsa SiC li sebelisoa haholo ho:

Likoloi tsa Motlakase (EV) Powertrains: Likarolo tse thehiloeng ho SiC tse kangli-inverterslematla a MOSFETntlafatsa bokgoni le tshebetso ya dikoloi tse tsamaisang motlakase ka ho etsa hore lebelo la ho tjhentjha ka potlako le matla a phahameng a matla. Sena se lebisa bophelong bo bolelele ba betri le ts'ebetso e ntle ka kakaretso ea koloi.

Li-charger tse ka Botong: Lisebelisoa tsa SiC li thusa ho ntlafatsa bokhoni ba lisebelisoa tsa ho tjhaja ka boto ka ho nolofalletsa linako tsa ho tjhaja ka potlako le tsamaiso e ntlafetseng ea mocheso, e leng ntho ea bohlokoa bakeng sa li-EV ho tšehetsa liteishene tsa ho tjhaja matla a phahameng.

Sistimi ea Taolo ea Battery (BMS): Theknoloji ea SiC e ntlafatsa katleho eatsamaiso ea betri, e lumellang hore ho be le taolo e betere ea motlakase, ho sebetsana le matla a holimo, le bophelo bo bolelele ba betri.

Lisebelisoa tsa DC-DC: Li-wafers tsa SiC li sebelisoa hoLi-converter tsa DC-DCho fetolela matla a DC a nang le matla a phahameng ho ea ho matla a tlaase a DC ka mokhoa o atlehileng haholoanyane, e leng sa bohlokoa likoloing tsa motlakase ho laola matla a tsoang betri ho ea likarolong tse sa tšoaneng tsa koloi.

Ts'ebetso e phahameng ea SiC ho li-voltage tse phahameng, mocheso o phahameng, le ts'ebetso e phahameng ea ts'ebetso e etsa hore e be ea bohlokoa bakeng sa phetoho ea indasteri ea likoloi ho ea ho motsamao oa motlakase.